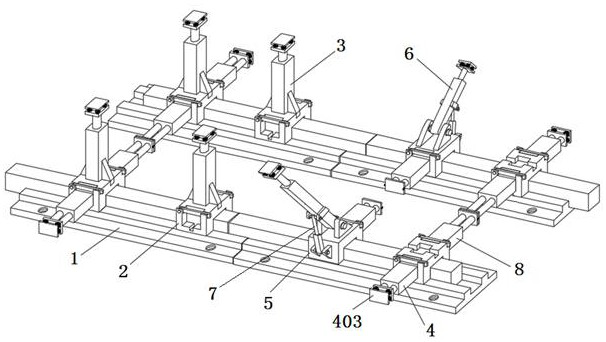

Fast-splicing and fast-dismounting type tunnel temporary rod piece supporting device

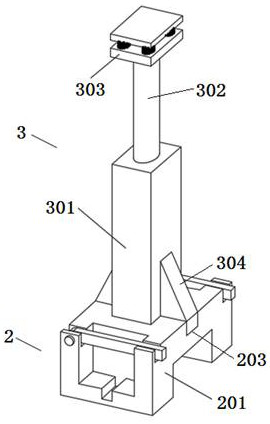

A supporting device and temporary rod technology, which is applied in the direction of tunnels, tunnel linings, temporary shields, etc., can solve the problems of affecting the overall support effect of rods, poor support ground contact effect, low material reuse rate, etc., to achieve the working form The conversion process is efficient and orderly, the support effect is good, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0064] s1. Preparatory work: Use relevant technical measures to clarify the cracking and deformation section of the tunnel structure, and then level the ground of the corresponding section. If necessary, add a layer of gravel cushion or use poor concrete mixed on site for ground reinforcement and maintenance. Leveling;

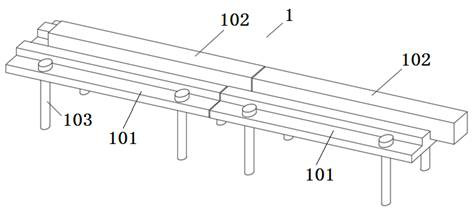

[0065] s2. According to the deformation of the tunnel structure, determine the temporary support reinforcement plan, including determining the support section spacing and section support form, and arrange the expanded steel beam foundation 1 on the ground of the corresponding section according to the temporary support reinforcement plan,

[0066] If the ground needs to keep the traffic of vehicles, when it is not suitable to arrange the telescopic connection unit body 8, the positioning steel pipe 103 should be opened to carry out the necessary positioning of the enlarged steel beam foundation 1; Open the positioning steel pipe 103;.

[0067]s3. After the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com