Lithium ion battery electrode preparation process and intaglio printing equipment

A lithium-ion battery and a preparation process technology are applied in the field of lithium-ion battery electrode preparation technology and gravure printing equipment, and can solve problems such as easy precipitation of lithium, increase areal density, improve production efficiency and service life, and avoid pole piece deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

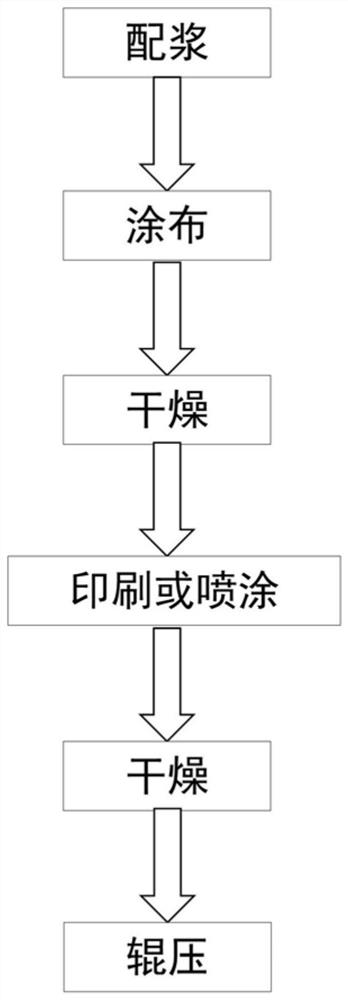

[0039] refer to figure 1 and image 3 In the lithium-ion battery electrode preparation process provided in this embodiment, after the coating is completed and dried, the negative electrode slurry layer is printed or sprayed on the negative electrode thinning area 51, and the thickness of the negative electrode slurry layer is less than 15 μm, preferably 4-5 μm , specifically 4 μm or 4.5 μm or 5 μm. The negative electrode slurry layer can be a common solid layered structure, or a hollowed-out layered structure.

[0040] In the lithium-ion battery electrode preparation process of this embodiment, after the drying is completed, the negative electrode slurry layer is printed or sprayed on the negative electrode thinned area 51, which can increase the area density of this area and increase the NP ratio, thereby improving the problem of lithium deposition in the negative electrode.

[0041] As a preferred solution of the above technical solution, the printing adopts gravure printi...

Embodiment 2

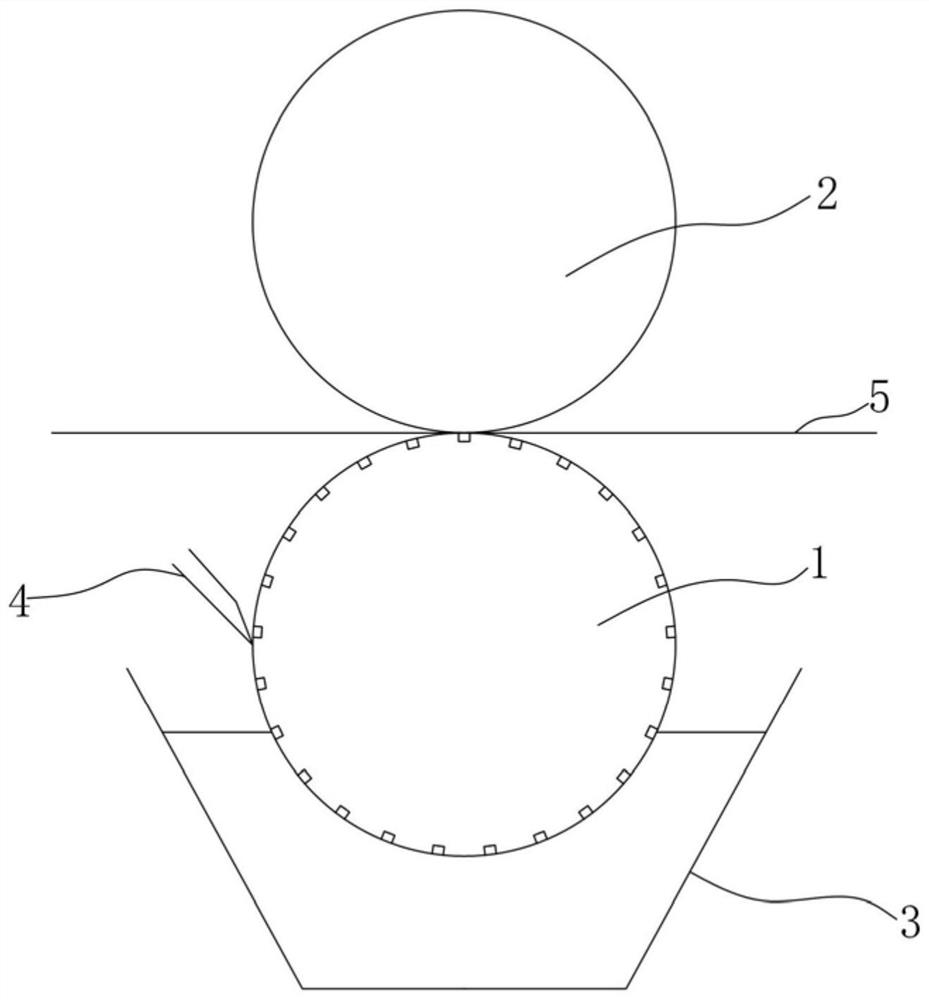

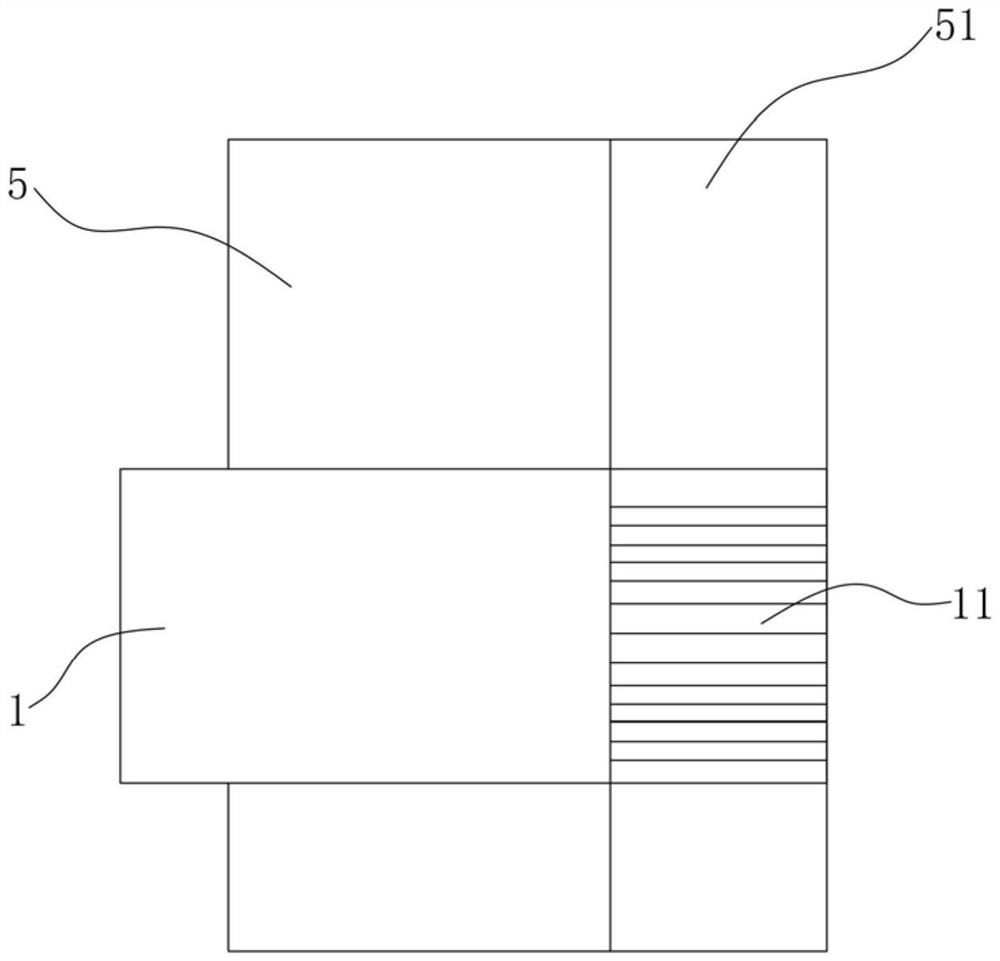

[0051] refer to figure 2and image 3 , the gravure printing equipment provided in this embodiment includes a printing plate cylinder 1 and an embossing cylinder 2 .

[0052] The printing plate cylinder 1 has a plurality of grooves evenly distributed along the circumferential direction on the circumferential surface of part of the shaft section to form a scoring area 11; the circumferential surface of the remaining part of the shaft section is a smooth surface, which is used to remove the thinning area of the pressing pole piece other parts of. The shape of the grooves is not limited, and can be strip grooves, circular grooves, triangular grooves or other common groove shapes. No matter what groove shape is used, as long as it is evenly distributed, it will increase the surface density of the negative electrode thinned region 51 . Preferably, the groove is a strip-shaped groove, and the length direction of the strip-shaped groove is parallel to the axial direction of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com