Full-reverse type low-loss lithium carbonate battery recycling and regenerating equipment

A technology of battery recycling and regeneration equipment, applied in battery recycling, secondary batteries, recycling technology, etc., can solve the problems of recycling efficiency and low utilization rate, waste battery sorting, etc., to achieve efficiency and utilization rate improvement, The effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0042] Such as Figure 26 As shown, a lithium battery generally includes a battery case, a battery cell, a negative terminal arranged at the closed end of the battery case, a positive terminal embedded in the open end of the battery case, and a paste between the positive terminal and the battery cell, which includes a diaphragm, electrolyte, etc. , the diaphragm is generally wound in a layer-by-layer helical order.

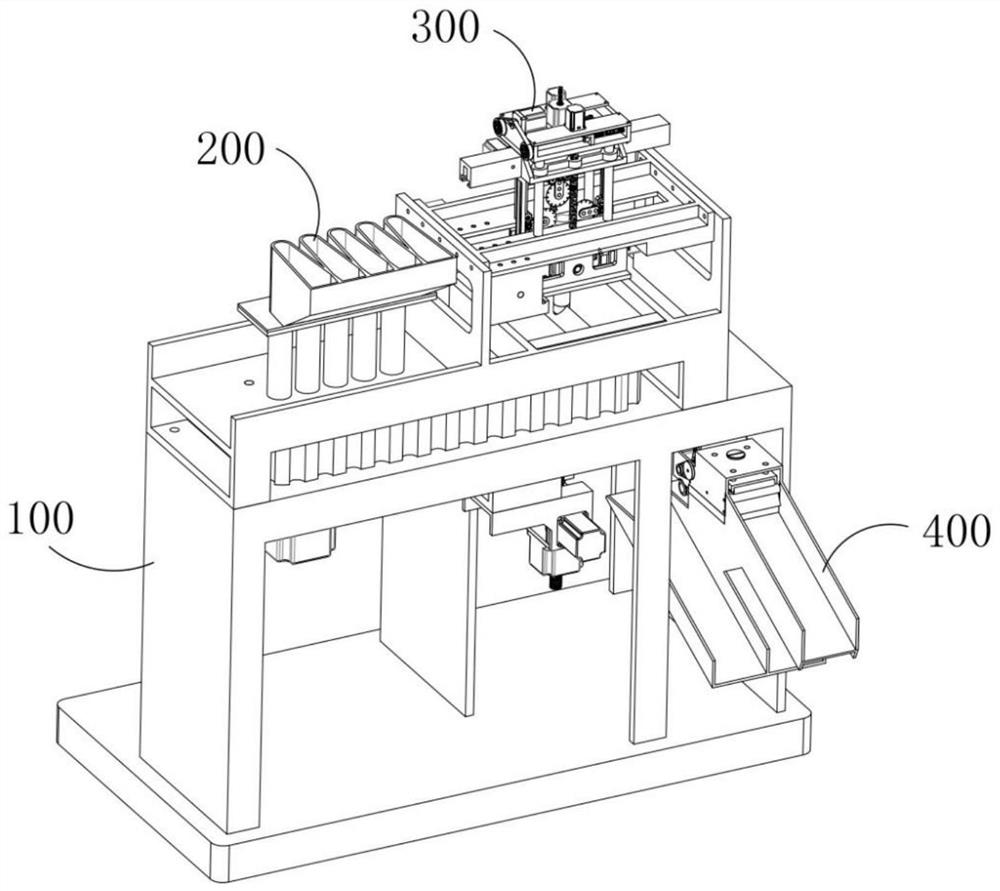

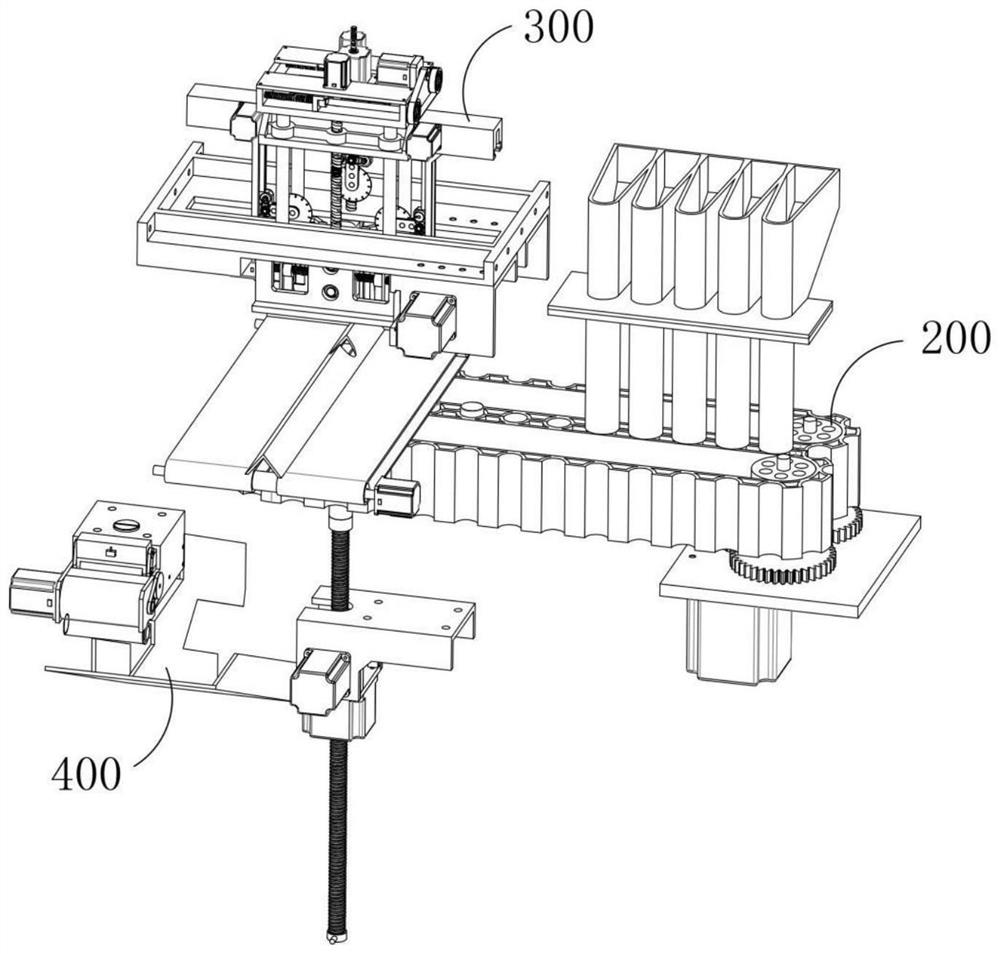

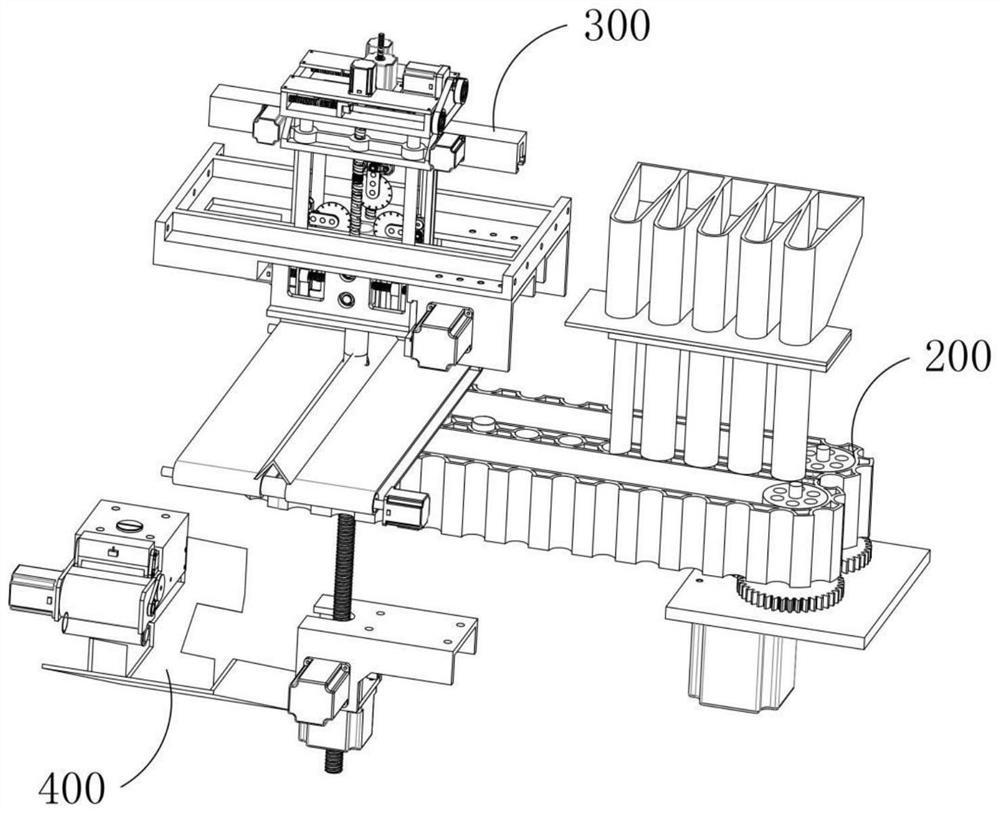

[0043] Such as Figure 1-5 As shown, a full-reverse low-loss lithium carbonate battery recovery and regeneration equipment includes a frame 100, a feeding device 200, a shell separation device 300, and a core separation device 400 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com