Modulator chip assembly for high rate optical signal generation

A high-speed signal and modulator technology, used in laser parts, lasers, semiconductor lasers, etc., can solve the problem of insufficient 50Gb/s signal modulation, and achieve the effect of ensuring mass production, realizing bandwidth, and overcoming bandwidth limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

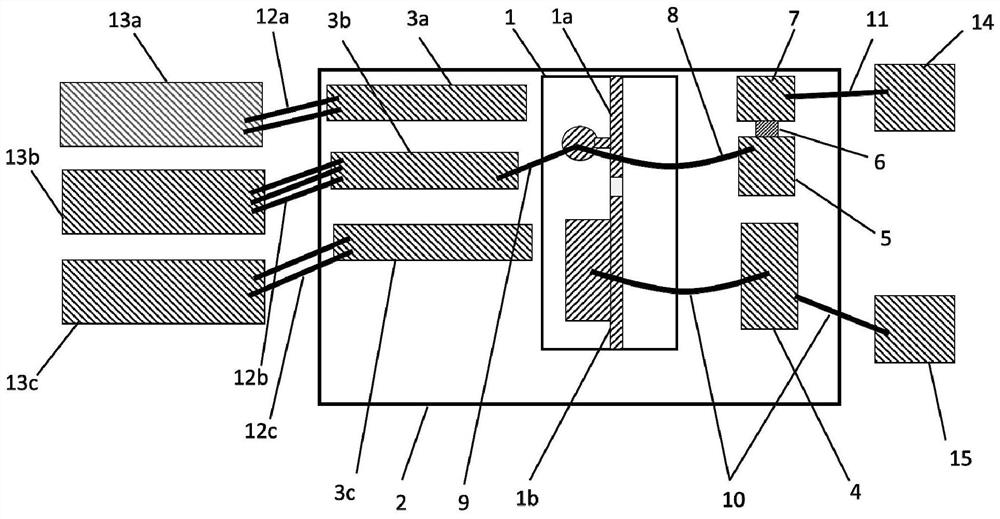

[0066] Such as Figure 5 As shown, the modulator chip assembly used for high-speed optical signal generation in the present invention includes an electroabsorption modulation laser 1, a capacitor 17, a second inductance 16, a first inductance 18, and a matching resistor 6; wherein the electroabsorption modulation laser 1 includes an electroabsorption modulator 1a and a semiconductor laser 1b. A high-speed electrical signal is applied to the electroabsorption modulator 1a to modulate the DC light emitted by the semiconductor laser 1b to generate a high-speed optical signal output; all these components (including the electroabsorption modulation laser 1, capacitor 17 , the second inductor 16, the first inductor 18 and the matching resistor 6) are all located on the same substrate 2;

[0067] The substrate 2 also includes a plurality of microwave transmission lines and electrodes for connecting external circuits and electroabsorption modulated lasers, and resistors 6 (generally 5...

Embodiment 2

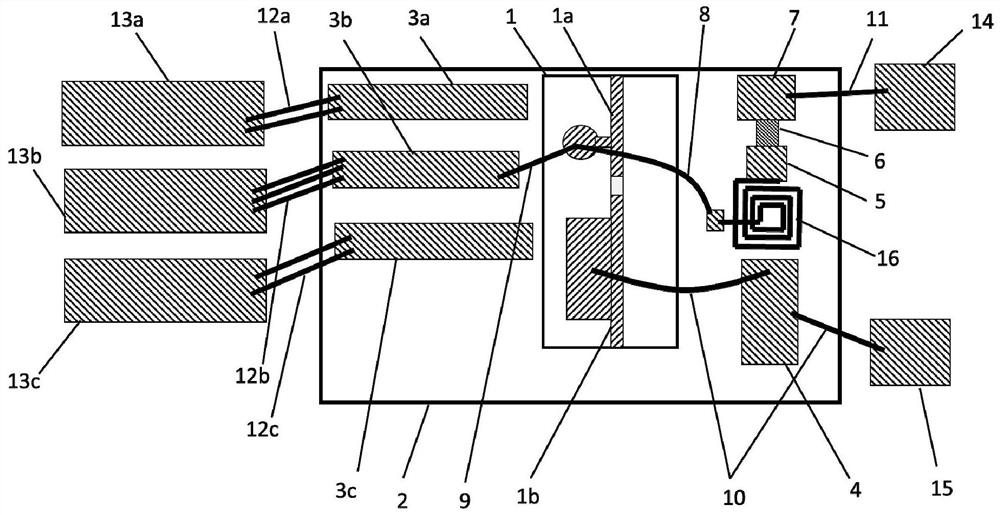

[0082] Such as Figure 12 As shown, the first inductor 18 that was originally located on the same substrate 2 as the capacitor 17 is replaced by a first gold wire 91 of a certain length; the first gold wire 91 not only provides the connection between the signal line 3b and the modulator chip 1a, but also acts as the first inductor 18. Compared with Embodiment 1, Embodiment 2 replaces the first inductor 18 with a gold wire, which can not only reduce the cost, but also because the length of the gold wire can be adjusted during chip packaging, and the inductance value also changes accordingly, so gold wires of different lengths The wire will be able to function as an adjustable inductance. Since the parameters of modulator chips from different suppliers are different, adjusting the inductance value by changing the length of the first gold wire 91 will greatly facilitate the adjustment of resonance characteristics for different modulator chips to obtain the best response performa...

Embodiment 3

[0084] Going a step further, as in Figure 13 As shown, the first inductor 18 originally located on the same substrate 2 as the capacitor 17 is replaced by a first gold wire 92 of a certain length, and the second inductor 16 is replaced by a second gold wire 82 . The first gold wire 92 not only provides the connection between the signal wire 3 b and the modulator chip 1 a, but also acts as the first inductor 18 , and the second gold wire 82 acts as the second inductor 16 . Compared with Embodiment 1, Embodiment 3 replaces the first inductance 18 and the second inductance 16 with two first gold wires 92 and second gold wires 82 of different lengths, which not only can further reduce the cost, but also because the length of the gold wires It can be adjusted when the chip is packaged, and the inductance value will also change accordingly, so gold wires of different lengths will be able to play the role of adjustable inductance. On the premise of considering the parasitic effect,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com