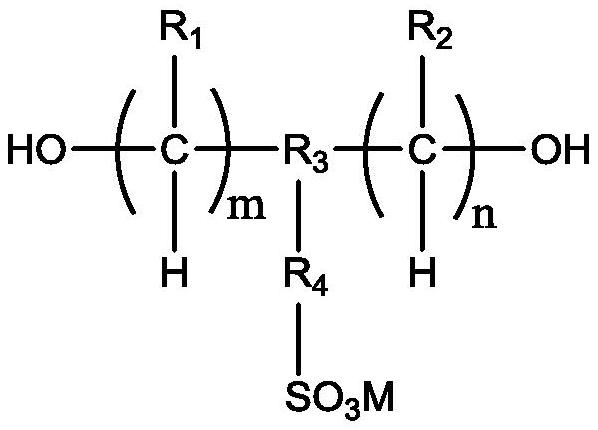

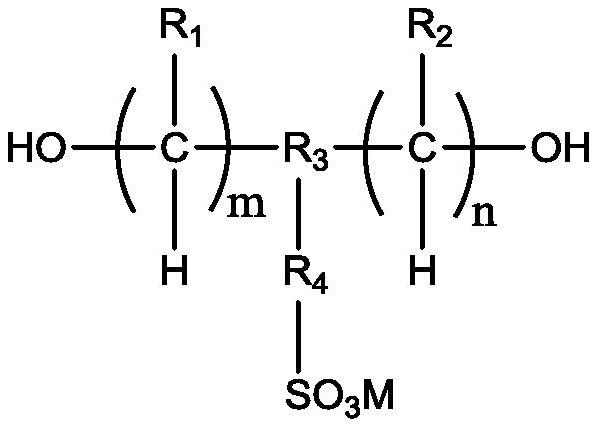

Amphiphilic polycaprolactone polyol as well as preparation method and application thereof

A polycaprolactone and amphiphilic technology, applied in the field of polyols, can solve the problems of increasing VOC content, poor acid and alkali resistance of carboxylates of hydrophilic groups, poor storage stability and pH stability of polyurethane emulsion, etc., to achieve The effect of stable storage and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

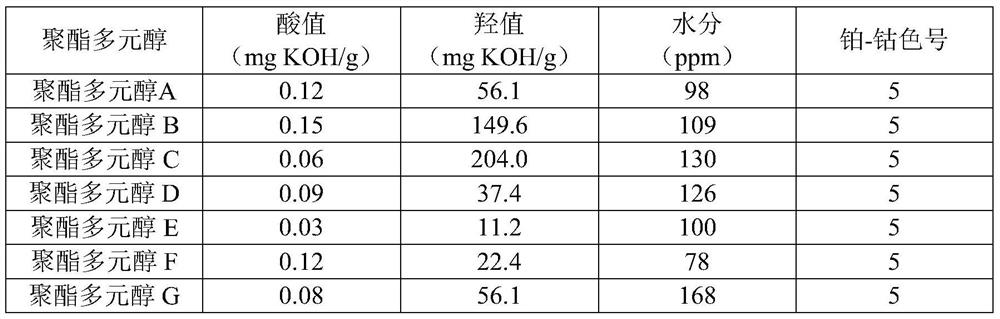

Embodiment 1

[0061] Add 2.50kg of initiator 1,4-butanediol-2-sodium sulfonate and 23.61kg of caprolactone into the reaction kettle, raise the temperature to 180°C, add 1.31g of stannous octoate, react for 4h, - Vacuumize at 0.090 kPa gauge pressure for 2 hours to remove unreacted monomers, cool to 150°C and discharge to obtain amphiphilic polycaprolactone polyol A with a hydroxyl value of 56.1 mg KOH / g.

Embodiment 2

[0063] Add 2.50kg of initiator 1,4-butanediol-2-sodium sulfonate and 7.27kg of caprolactone into the reaction kettle, raise the temperature to 180°C, add 1.66g of dibutyltin dilaurate, and react for 5h , Vacuum at -0.090kPa gauge pressure for 1h to remove unreacted monomers, cool down to 150°C and discharge to obtain amphiphilic polycaprolactone polyol B with a hydroxyl value of 149.6mg KOH / g.

Embodiment 3

[0065] Add 2.50kg of initiator 1,4-butanediol-2-sodium sulfonate and 4.68kg of caprolactone into the reaction kettle, raise the temperature to 160°C, add 2.15g of zinc 2-hexylhexanoate, and react 5h, vacuumize at -0.090kPa gauge pressure for 1.5h to remove unreacted monomers, cool down to 150°C and discharge to obtain amphiphilic polycaprolactone polyol C with a hydroxyl value of 204.0mg KOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com