Preparation method of anti-aging agent 6PPD

An anti-aging agent and decarboxylation technology, applied in the field of preparation of anti-aging agent 6PPD, can solve the problem of high oxide content, and achieve the effects of improving melting point, improving safety and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

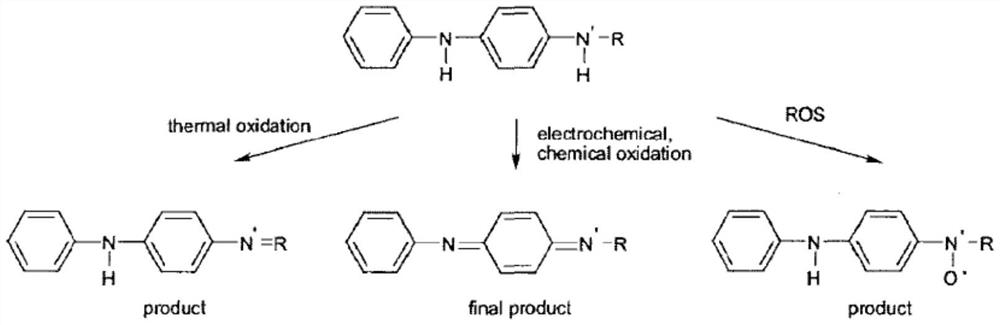

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Step 1: Cashew nut shell oil is decarboxylated and rectified at high temperature to obtain cardanol;

[0031] Step 2: reacting the cardanol obtained by rectification with the alkyl halide to generate the corresponding cardanol;

[0032] Step 3: react cardanol with anti-aging agent 6PPD to generate macromolecular anti-aging agent 6PPD containing cardanol structure.

[0033] Further, the temperature of high-temperature decarboxylation in step 1 is 50°C to 350°C.

[0034] Further, the decarboxylation rectification in step one is atmospheric rectification or vacuum rectification.

[0035] Further, the pressure of vacuum rectification is 0-20kPa.

[0036] Further, the haloalkane in step 2 is chloroalkane or bromoalkane.

[0037] Further, the etherification reaction temperature in step 2 is 55°C-85°C.

[0038] Furthermore, the reaction temperature of the cashew nut ether and the anti-aging agent 6PPD in step 3 is 35°C-80°C.

[0039] The invention discloses a method for...

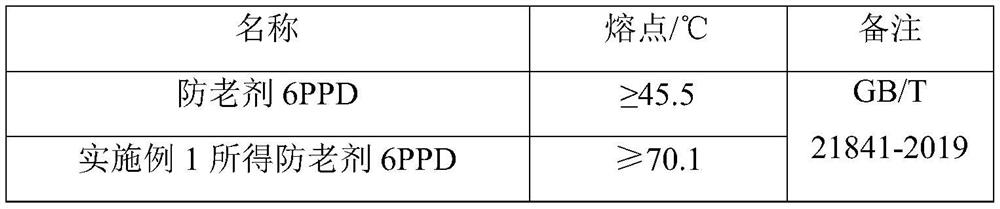

Embodiment 1

[0042] Weigh 60g of cashew nut shell oil and heat it in an oil bath in a 100mL three-necked flask, and carry out decarboxylation and rectification at atmospheric pressure. React with 14.5g of 1,2-dibromoethane at a constant temperature of 60°C for 5 hours. After the reaction, process the reaction solution to obtain a brown-red liquid cashew ether. Weigh 20g of anti-aging agent 6PPD and polymerize it with cashew ether. The polymerization temperature is 65°C , after reacting for 5 hours, the anti-aging agent 6PPD containing cardanol structure was obtained.

Embodiment 2

[0044] Weigh 60g of cashew nut shell oil and heat it in an oil bath in a 100mL three-neck flask to carry out decarboxylation rectification under reduced pressure. The distillate was reacted with 21.4g of 1,2-dibromoethane under the action of potassium hydroxide at a constant temperature of 55°C for 6 hours. After the reaction, the reaction solution was processed to obtain a light yellow liquid cashew ether. Weighed 29.5g of anti-aging agent 6PPD and Cardanol ether is polymerized at a temperature of 60° C. After 5 hours of reaction, an antioxidant 6PPD containing a cardanol structure is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com