Double-in-and-out chamber type filter plate assembly and corresponding double-in-and-out chamber type automatic filter press

A filter plate and component technology, which is applied in the field of box-type automatic filter presses, can solve the problems of low single input and output efficiency, leakage of filter plates, etc., and achieve the effect of reducing the area occupied by the filter plate, high production efficiency, and increasing the effective volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

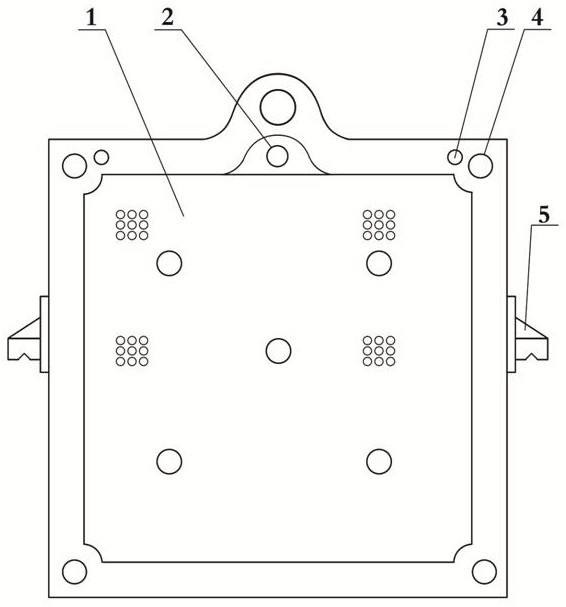

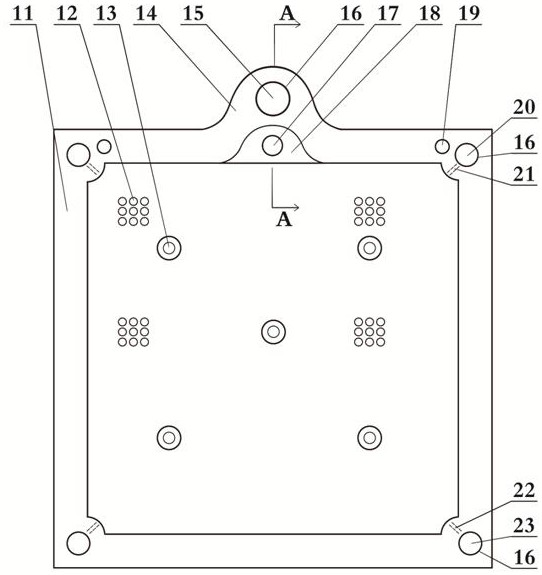

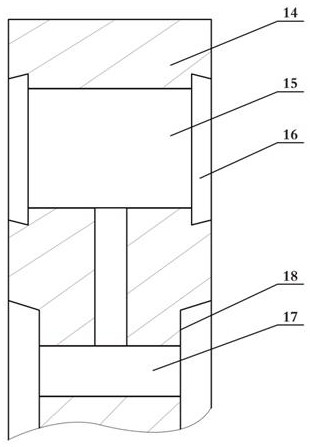

[0022] An upper single-ear feed box filter plate 1 (abbreviation: upper ear filter plate), the main points of the innovative overall implementation plan are: to give the filter plate 1 single-hole two-way feed, double-hole one-way water or air, and double-hole The double-inlet and outflow characteristics of the one-way undercurrent effluent, in which the existing double-hole one-way feeding method is improved to a single-ear hole two-way feeding method, which reduces the area of the filter plate occupied by the feeding hole and improves the uniformity of the feeding; Some fluid orifice-mounted sealing rings are improved to orifice-mounted trapezoidal double-lip sealing rings 4, which reduces the area of the filter plate occupied by the sealing groove and improves the high-pressure automatic sealing performance; an elastic rubber pad 3 is added to automatically spring (correct) the filter The plate verticality deviation ensures that the surrounding filter frames are uniforml...

Embodiment 2

[0040] A double-inlet box-type filter plate assembly (hereinafter referred to as: filter plate assembly), mainly composed of an upper single-ear feed filter plate 1, a cloth distributor 2, a pull plate correction spring washer 3, and a trapezoidal double-lip sealing ring 4 , filter plate support handle 5 and other components; the main points of the innovative overall implementation plan are: to give the filter plate 1 the dual-inlet and outlet characteristics of single-hole two-way feeding, double-hole one-way water or gas, and two-hole one-way dark outflow. Among them, the existing double-hole one-way feeding method is improved to a single ear hole two-way feeding method, which reduces the area of the filter plate occupied by the feeding hole 15, and improves the uniformity of feeding; the existing fluid hole end embedded seal ring It is improved to an orifice-mounted trapezoidal double-lip sealing ring 4, which reduces the area of the filter plate 1 occupied by the sealin...

Embodiment 3

[0048] An automatic filter press with double entry and exit chambers uses the double entry and exit chamber filter plate assembly provided by the invention. The double-inlet box-type automatic filter press is mainly composed of a frame, a pressing mechanism, a double-inlet filter mechanism, a plate pulling mechanism, a cloth washing mechanism, a liquid flap mechanism, a hydraulic drive mechanism, and a PLC program control system. The double inlet and outlet filter mechanism is the core mechanism of the filter press, mainly composed of double inlet and outlet box-type filter plate assemblies (invention), head and tail anti-corrosion filter plates, filter cloth, external pipelines for each inlet and outlet functions, and other components. The double-inlet box-type filter plate assembly is the key component of the double-inlet filter mechanism. It mainly consists of the upper single-ear feed filter plate 1, the cloth distributor 2, the pulling plate correction spring washer 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com