Rapid drilling rig for solid mineral exploration

A mineral and fast technology, applied in the field of fast drilling devices for solid mineral exploration, can solve the problems of insufficient fixation, insufficient fixation effect, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

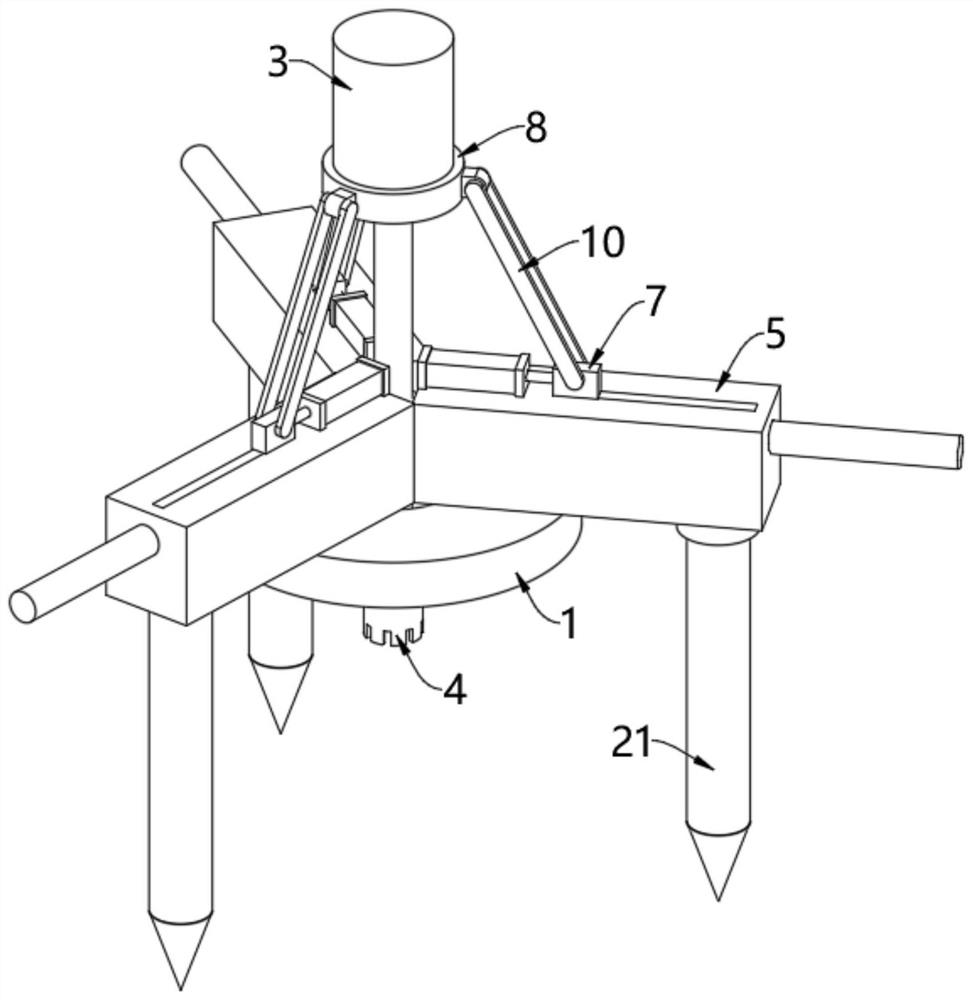

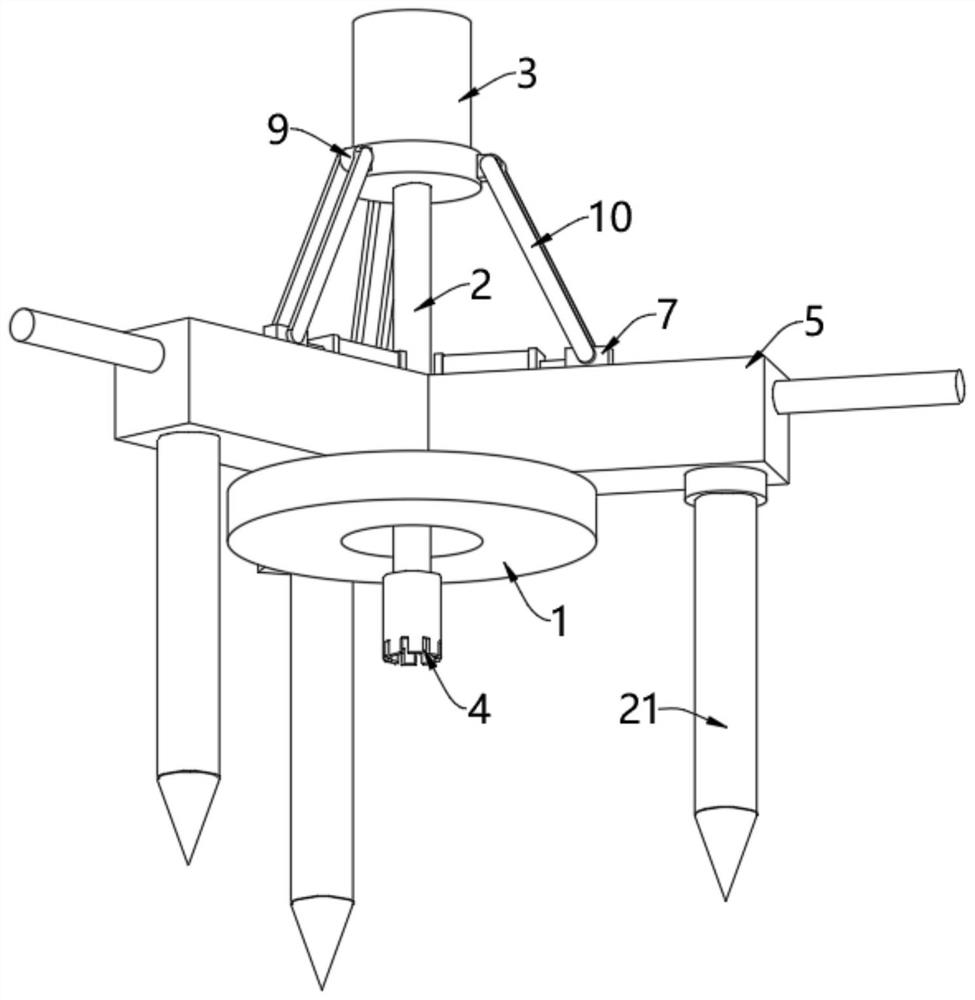

[0046] see figure 1 and figure 2 , a fast drilling device for solid mineral exploration, comprising a mounting ring 1, a drill rod 2 is arranged to rotate inside the mounting ring 1, the drill rod 2 is fixedly mounted on the bottom of the output shaft of a driving motor 3, and a drill bit is fixedly mounted on the bottom of the drill rod 2 4. Several fixed cabinets 5 are evenly arranged on the top of the installation ring 1, and several fixed cabinets 5 are arranged around the drill pipe 2. The tops of several fixed cabinets 5 close to the end of the drill pipe 2 are all fixedly installed with electric push rods 6, and the electric push rods A movable block 7 is fixedly installed on the top of the output shaft of the rod 6. In this embodiment, there are three fixed cabinets 5, electric push rods 6 and movable blocks 7;

[0047] The bottom of the drive motor 3 is fixedly installed with a mounting plate 8, and the edge of the mounting plate 8 is provided with a number of conne...

Embodiment 2

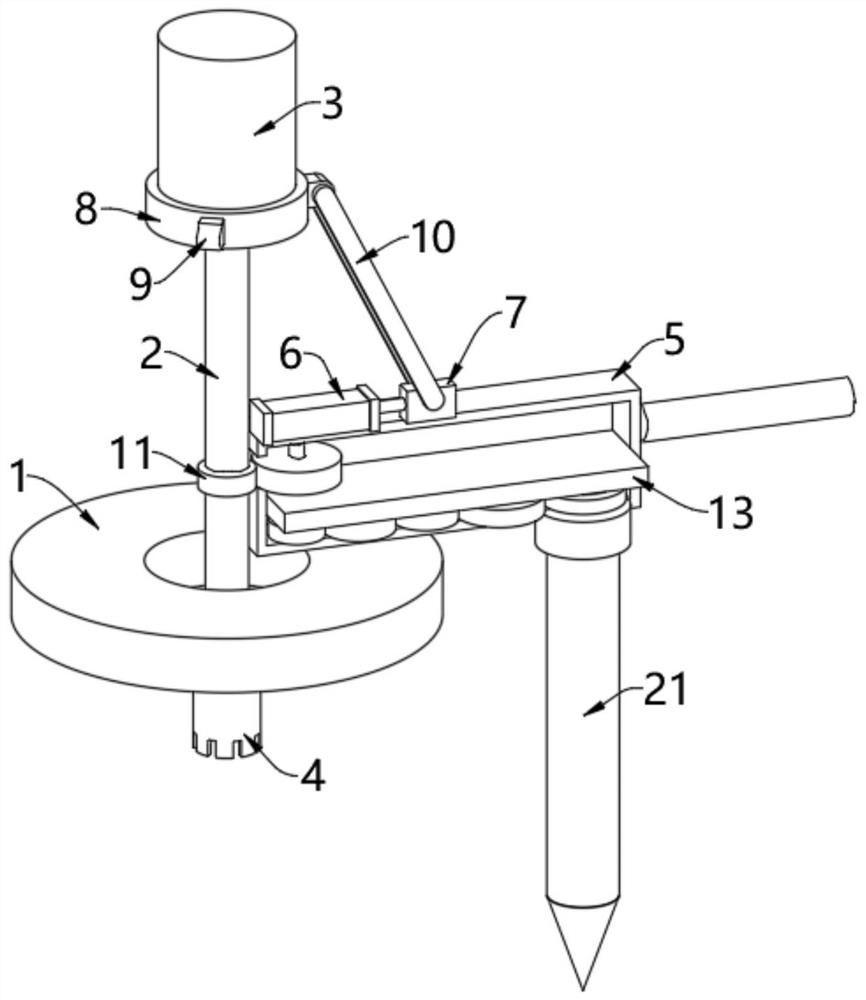

[0050] see Figure 3-Figure 5 , on the basis of Embodiment 1, the insides of several fixed cabinets 5 are all formed with inner chambers 12, and the insides of several inner chambers 12 are all horizontally provided with partitions 13, and partitions 13 divide the inner chambers 12 into upper control chambers and the lower drive chamber, the bottom of several fixed cabinets 5 is provided with bearings 22 at the end away from the drill pipe 2, and the inner walls of several bearings 22 are fixedly equipped with struts 21, which are arranged in the linkage between the drill pipe 2 and the struts 21. The mechanism is used to synchronously drive the support rod 21 to rotate when the drill rod 2 is at a preset position and is driven by the drive motor 3 to rotate. In this embodiment, specifically:

[0051] The linkage mechanism comprises a driving wheel 11, a first gear 14, a vertical shaft 15, a second gear 16, a third gear 17, a fourth gear 18, a fifth gear 19 and a driven wheel ...

Embodiment 3

[0055] see Figure 6-Figure 10 , on the basis of Embodiment 1 or Embodiment 2, handles 23 are fixedly installed on the ends of several fixed cabinets 5 away from the drill pipe 2, and the fixed cabinets 5 and the installation ring 1 are conveniently lifted through the handles 23, which is more convenient to use , and easy to carry;

[0056] The inside of the pole 21 is provided with two push plates 29 opposite to each other, and the opposite side of the two push plates 29 is provided with an insertion rod 30, which is inserted into the slot 31, and the slot 31 is opened on the pole 21. On the outer wall of the two push plates 29, when the two push plates 29 are far away from each other, the insertion rod 30 provided on the opposite side will protrude through the slot 31, so as to be inserted horizontally into the ground, and the insertion rod 30 can be inserted laterally into the ground to increase the size of the pole. The grasping force between 21 and the ground makes the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com