Low-resistance integrated lubricating oil filter

An integrated, low-resistance technology, which is applied to the installation/connection of pressure lubricants, lubricating components, and lubricant purification devices, can solve the problems of large resistance loss of one-way valves, and achieve reduced resistance loss, reduced resistance, The effect of stroke increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

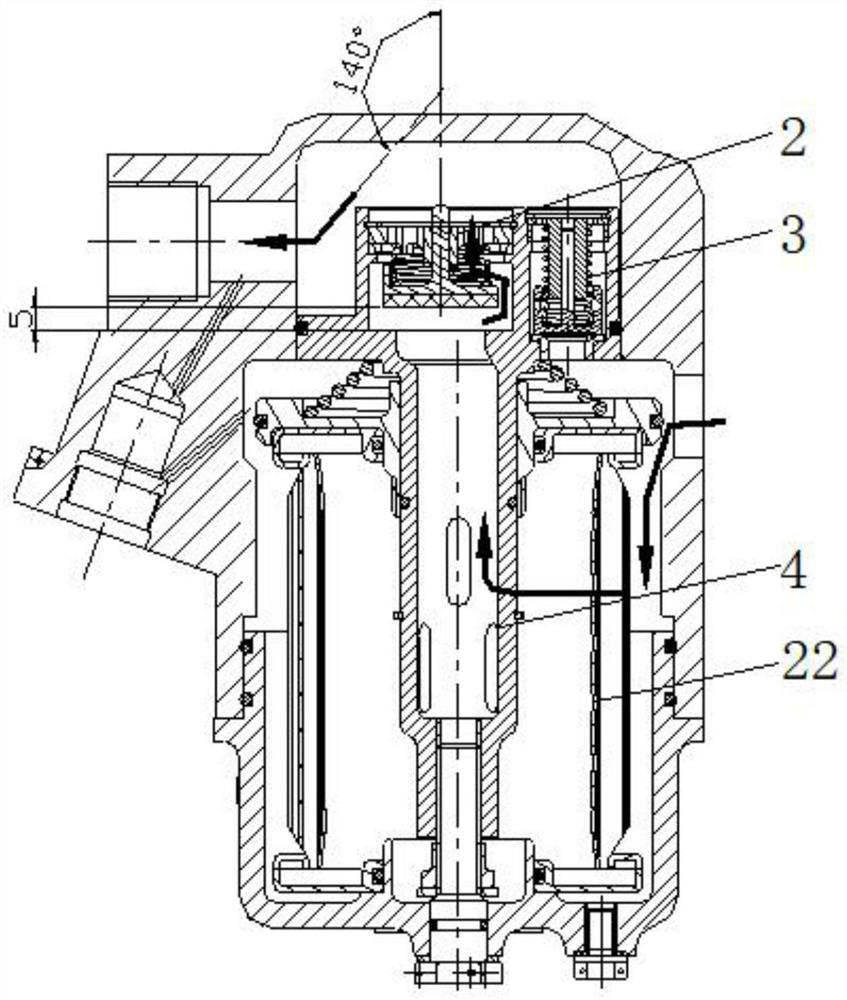

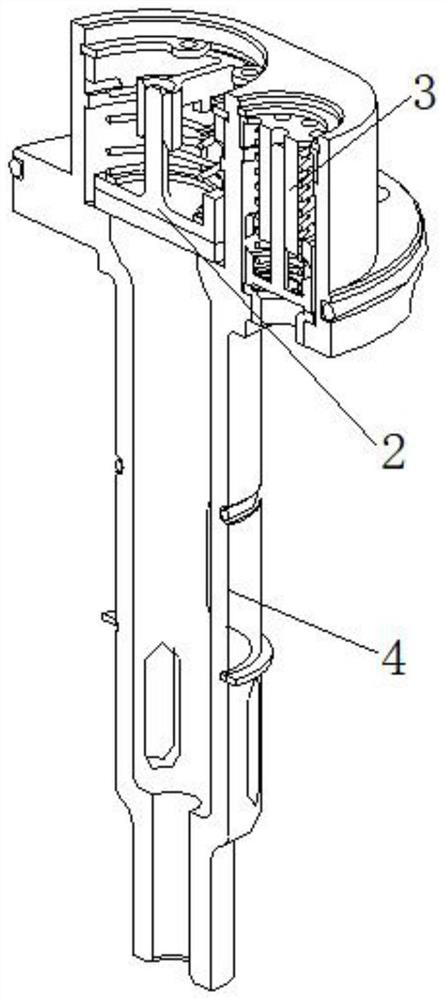

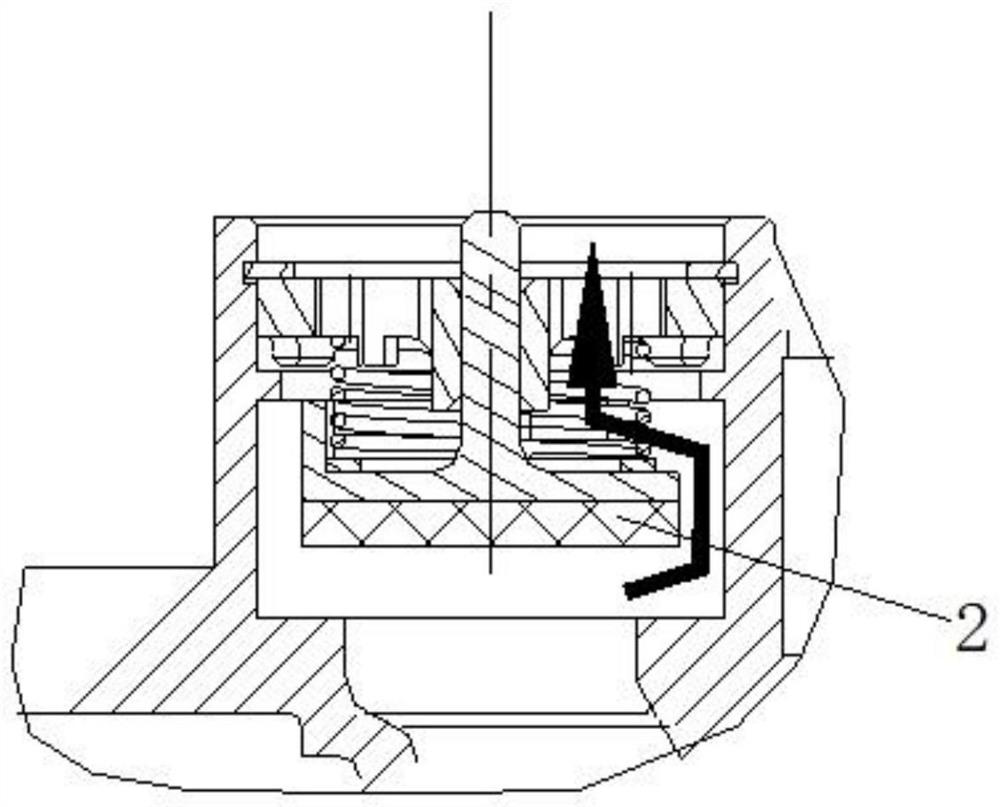

[0029] A low-resistance integrated lubricating oil filter, such as Figure 5-7 As shown, it includes a casing 1, an oil filter element 22, a one-way valve 2, a bypass valve 3 and a lubricating oil filter frame 4. The housing 1 is provided with an inner chamber for containing filter elements, the oil filter element 22, the one-way valve 2, the bypass valve 3 and the lubricating oil filter frame 4 are all arranged in the inner chamber, and the middle part of the housing 1 is provided with a lubricating oil inlet, and the housing 1 There is a lubricating oil outlet on the top. The oil filter element 22 is arranged coaxially along the center line of the casing 1 of the casing 1, and the lubricating oil filter f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com