Storage layout structure and warehouse-in and warehouse-out method thereof

A technology of layout structure, warehouse entry and exit, applied in the field of warehouse management, can solve the problems of increasing the demand for warehouse space, increasing the logistics cost, and unable to reduce the operating distance, so as to achieve the effect of reducing the distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

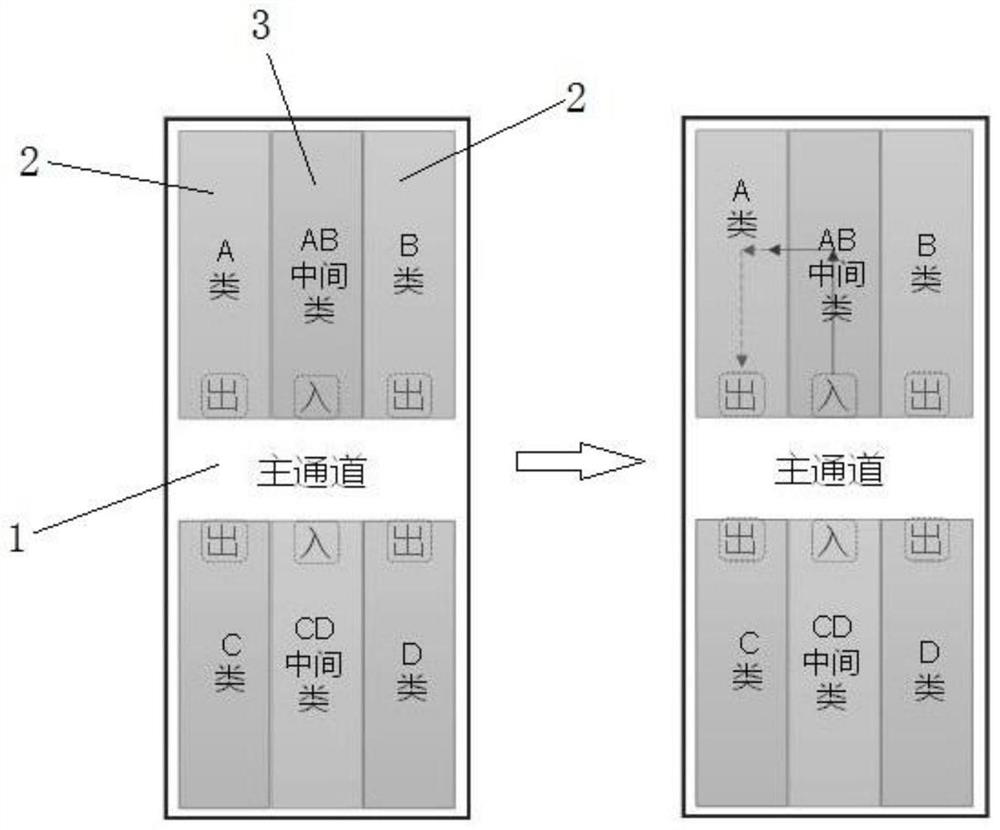

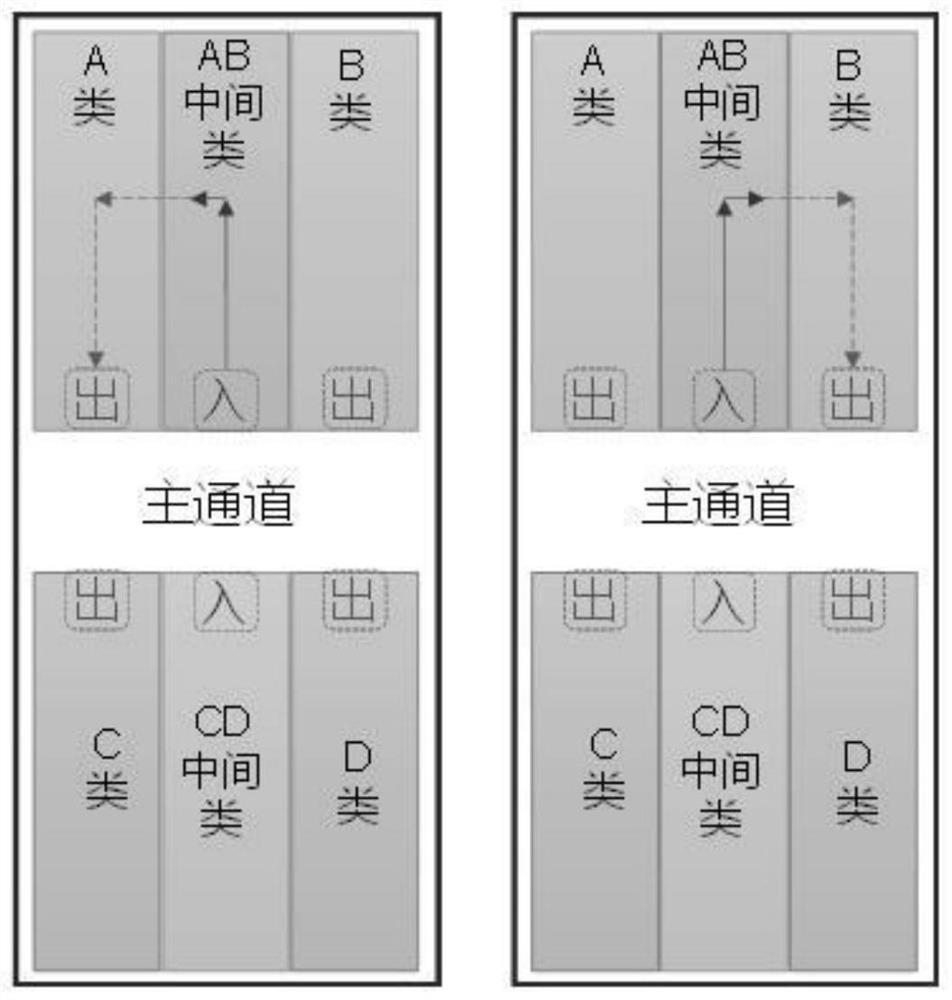

[0038] See figure 1 As shown, a warehouse layout structure of an embodiment is shown, wherein,

[0039] The warehouse is equipped with a main channel 1 that runs through to both ends in a straight line, and the two sides of the main channel 1 are sub-warehouse areas;

[0040] Based on the historical material sending and receiving information records, or the information about the same batch of incoming and outgoing information, the same batch of incoming or outgoing of the same batch is used as the main classification condition to classify the materials;

[0041] Two or more pieces of materials that are put into or out of the warehouse in the same batch are set as large-category materials and placed in sub-warehouse areas respectively to form large-category material area 2;

[0042] Set the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com