Lithium iron phosphate positive electrode active material, preparation method thereof, positive electrode plate and battery

A positive electrode active material, lithium iron phosphate technology, applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problem that the particle size and ratio of lithium iron phosphate materials cannot meet the closest packing and cannot effectively improve the compaction density And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of lithium iron phosphate cathode active material, comprising:

[0041] (1) Weigh lithium source (specifically lithium carbonate) and anhydrous ferric phosphate (wherein anhydrous ferric phosphate is used as phosphorus source and iron source at the same time) according to the molar ratio of Li:Fe:P at 1:1:1, Mix them with a carbon source (specifically glucose monohydrate), add a certain proportion of ethanol, and mix the above-mentioned materials uniformly through a high-speed disperser to make the first mixed slurry with a solid content of 45%; wherein, the carbon source The amount added can ensure that the theoretical carbon content of the first mixed slurry is 1.8% after being calcined at 790°C;

[0042] Transfer the first mixed slurry to a sand mill, grind until the particle size D50 of the slurry is about 550nm, obtain the first spray material, and spray dry the first spray material to obtain the first dry material; wherein, spray drying The i...

Embodiment 2

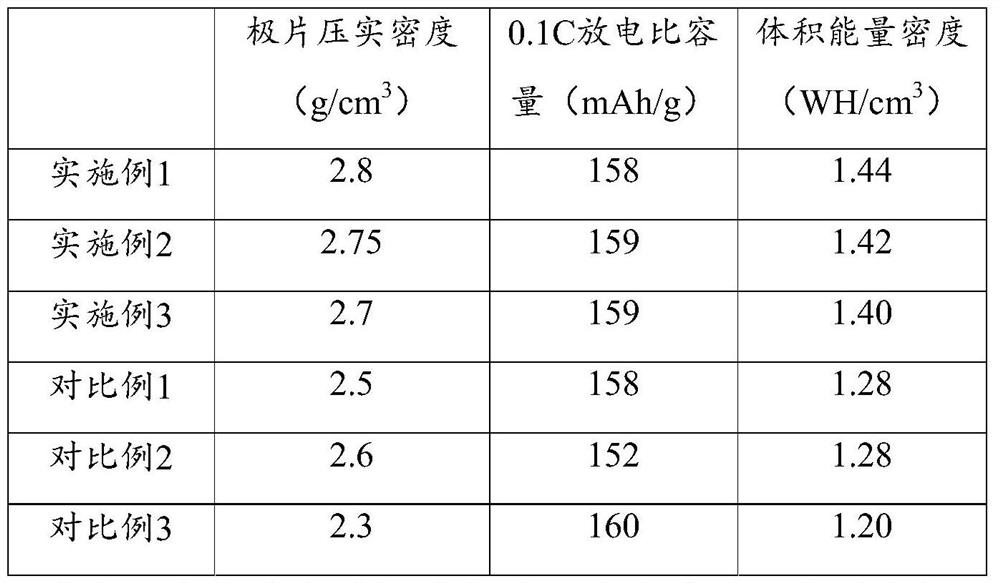

[0063]A method for preparing a lithium iron phosphate positive electrode active material, the difference from Example 1 is that: the amount of carbon source added in the first mixed slurry makes the theoretical carbon content of the first dry material after roasting at 750°C 1.6%; the second The amount of carbon source added in the second mixed slurry makes the theoretical carbon content of the second dry material after roasting at 750°C be 1.2%; the added amount of carbon source in the third mixed slurry makes the third dried material after roasted at 750°C The theoretical carbon content is 0.9%; the first dry material, the second dry material and the dry material are mixed in a mass ratio of 20%:20%:60%. The carbon content in the lithium iron phosphate cathode active material obtained in Example 2 was 1.1%.

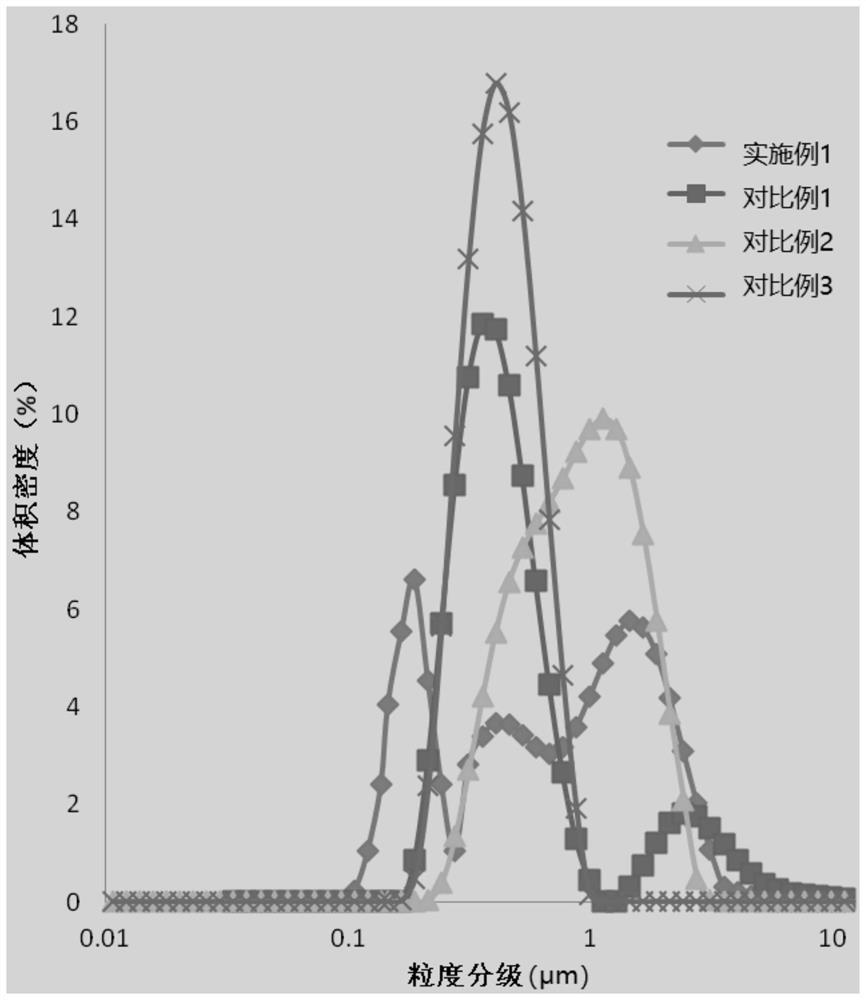

[0064] There are three peaks in the particle size distribution frequency curve (by volume percentage) of the lithium iron phosphate cathode active material in Example 2...

Embodiment 3

[0066] A method for preparing a lithium iron phosphate positive electrode active material, the difference from Example 1 is that: the amount of carbon source added in the first mixed slurry makes the theoretical carbon content of the first dry material after roasting at 700°C 1.4%; the second The amount of carbon source added in the second mixed slurry makes the theoretical carbon content of the second dried material at 1.0% after roasting at 700°C; the added amount of carbon source in the third mixed slurry makes the third dried material after roasted at 700°C The theoretical carbon content is 0.8%; the first dry material, the second dry material and the dry material are mixed in a mass ratio of 15%:19%:66%. The carbon content in the lithium iron phosphate cathode active material obtained in Example 3 was 0.95%.

[0067] There are three peaks in the particle size distribution frequency curve (by volume percentage) of the lithium iron phosphate cathode active material in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com