Miniaturized non-contact waveguide transmission line and application

A waveguide transmission line, non-contact technology, applied in the direction of waveguide, waveguide-type devices, circuits, etc., can solve the problems of passive intermodulation interference, affecting the performance of circuit components and systems, and increasing the size of waveguide, so as to reduce surface treatment process and Assembly process requirements, realize small compactness and light weight, and reduce the effect of lateral size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

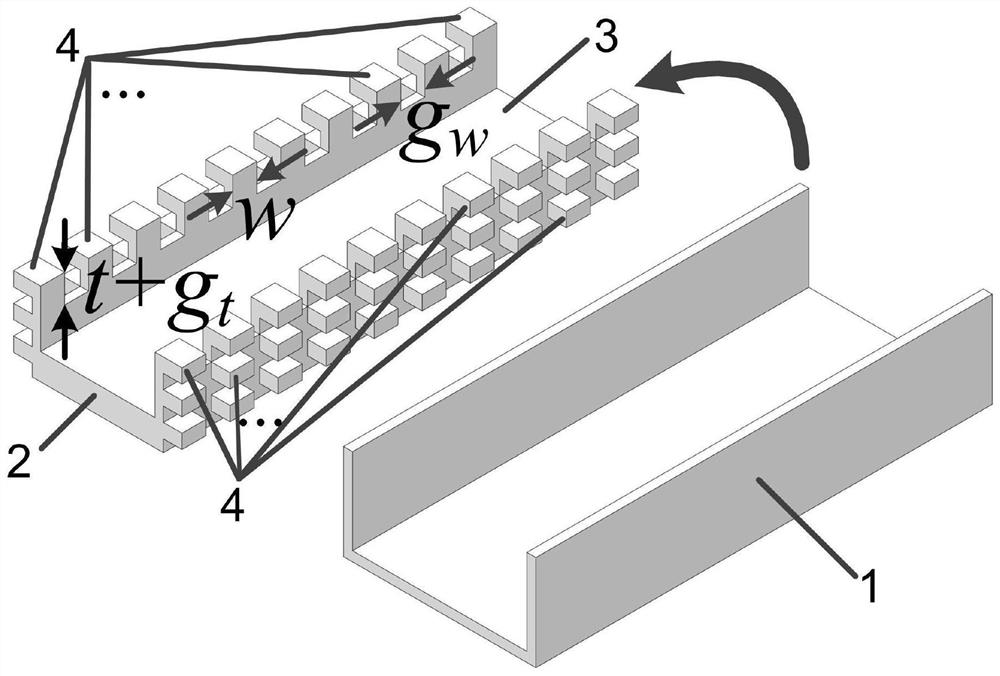

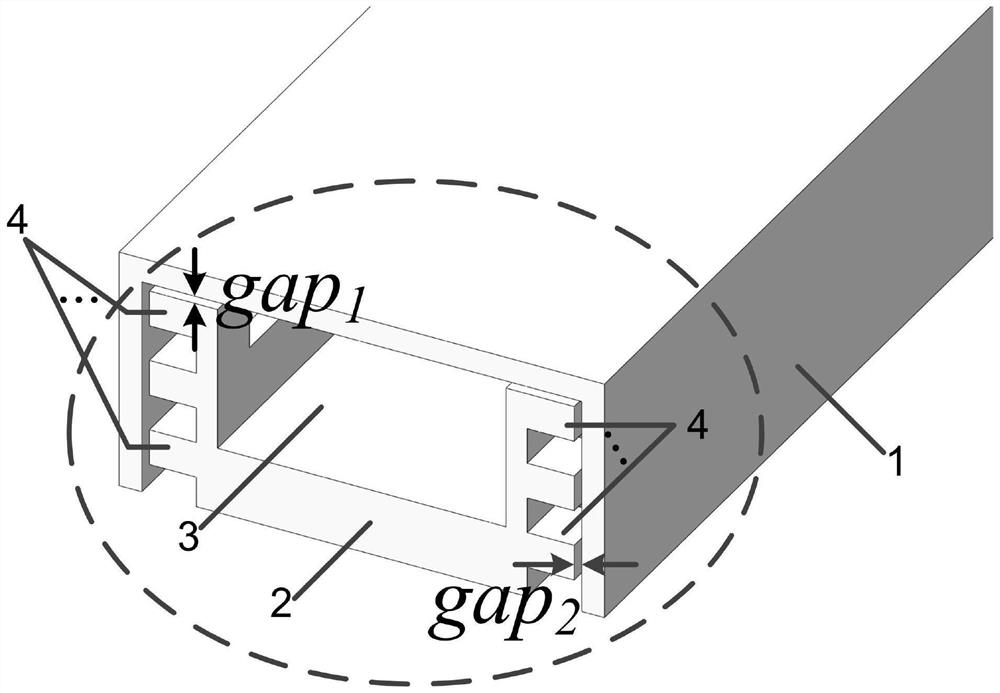

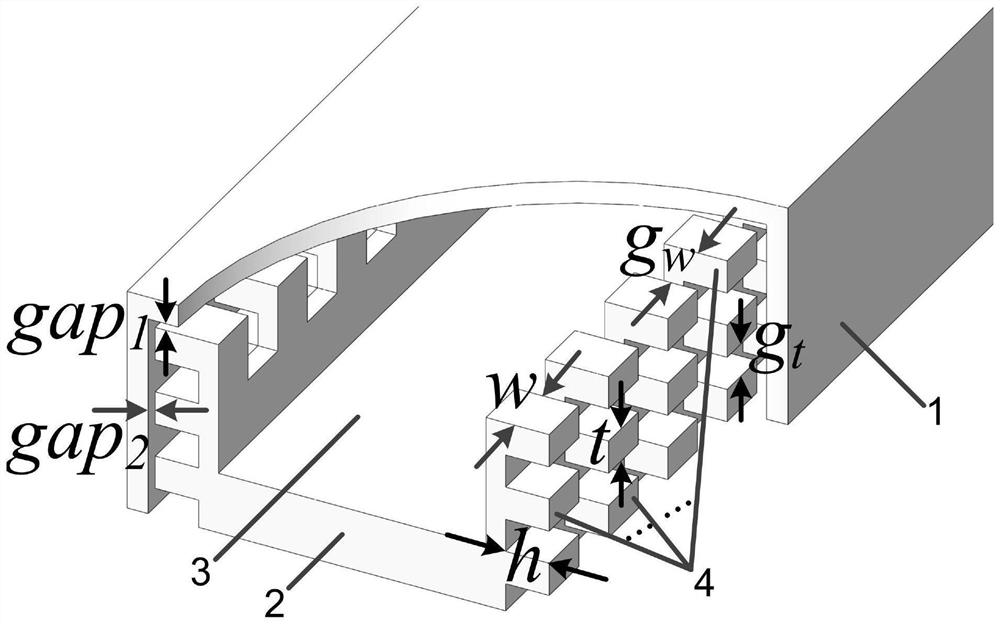

[0070] like Figure 1 - Figure 3 As shown, the miniaturized non-contact waveguide transmission line provided by the present invention includes at least a waveguide upper cover 1 and a waveguide substrate 2, wherein the waveguide upper cover 1 is a rectangular groove-shaped structure, the length of the groove is equal to the length, groove of the waveguide base 2. The width is greater than or equal to the width of the waveguide base 2, the groove depth is greater than or equal to the height of the waveguide substrate 2; the waveguide base 2 includes a waveguide groove 3 and a periodic metal protrusion array 4. The periodic metal protrusion array 4 includes several highly identical rectangular columnar metal protrusions, uniformly disposed of a rush of a row, uniformly disposed on both sides of the waveguide groove 3; the waveguide upper cover 1 is nested on the waveguide matrix 2, waveguide The upper surface of the inner wall of the cover 1 is between the surface of the side wall of...

Embodiment 2

[0093] Structure Figure 9 As shown, a miniaturized non-contact waveguide transmission line includes at least the waveguide upper cover 1 and the waveguide base 2, the waveguide upper cover 1 is a rectangular groove-shaped structure, the length of the groove is equal to the length of the waveguide base 2, and the groove width is greater than or equal to. The width of the waveguide base 2, the groove depth is greater than or equal to the height of the waveguide base 2; the waveguide base 2 includes a waveguide groove 3 and a periodic metal protrusion array 4. The periodic metal protrusion array 4 includes several highly identical rectangular columnar metal protrusions, uniformly disposed of a rush of a row, uniformly disposed on both sides of the waveguide groove 3; the waveguide upper cover 1 is nested on the waveguide matrix 2, waveguide The upper surface of the inner wall of the cover 1 is between the surface of the side wall of the waveguide groove 3 presents a gap GAP 1 , There...

Embodiment 3

[0096] Structure Figure 11 As shown, a miniaturized non-contact waveguide transmission line includes at least the waveguide upper cover 1 and the waveguide base 2, the waveguide upper cover 1 is a rectangular groove-shaped structure, the length of the groove is equal to the length of the waveguide base 2, and the groove width is greater than or equal to. The width of the waveguide base 2, the groove depth is greater than or equal to the height of the waveguide base 2; the waveguide base 2 includes a waveguide groove 3 and a periodic metal protrusion array 4. The periodic metal protrusion array 4 includes several highly identical rectangular columnar metal protrusions, uniformly disposed of a rush of a row, uniformly disposed on both sides of the waveguide groove 3; the waveguide upper cover 1 is nested on the waveguide matrix 2, waveguide The upper surface of the inner wall of the cover 1 is between the surface of the side wall of the waveguide groove 3 presents a gap GAP 1 , Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com