Energy feedback device in converter load test

A technology of energy feedback and load test, applied in the field of converters, to reduce costs, simplify the overall circuit, and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

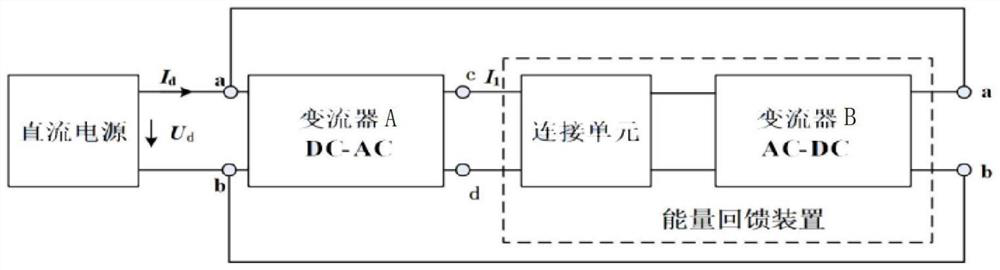

[0022] Such as figure 1 As shown, the present invention provides an energy feedback device in a converter load test, including an energy feedback device, a converter A and a DC power supply, the energy feedback device includes a connection unit and a converter B, and the converter carries out During the load test, a load must be connected to its output terminal. Normally, the output power is consumed at this load. In order to save energy, energy feedback should be carried out. During the load test, the converter A converts the DC power of the DC power supply into AC power, and its output is connected to the converter B through the connection unit. The converter B converts the AC power into a DC power and feeds it back to the input terminal of the converter A. Together with the DC power supply, power is supplied to the converter A, thereby realizing energy saving.

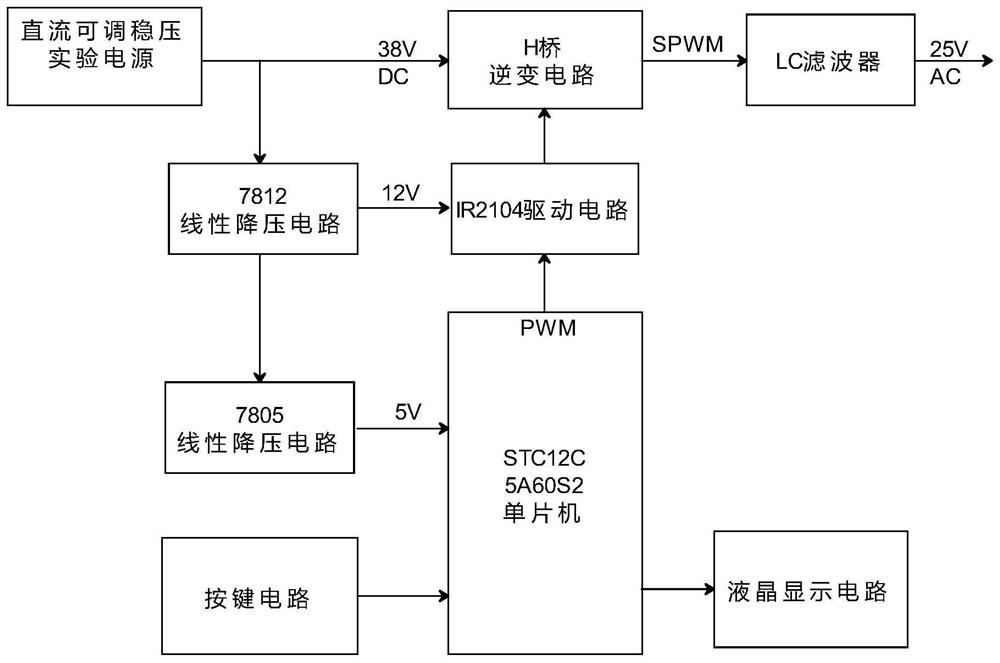

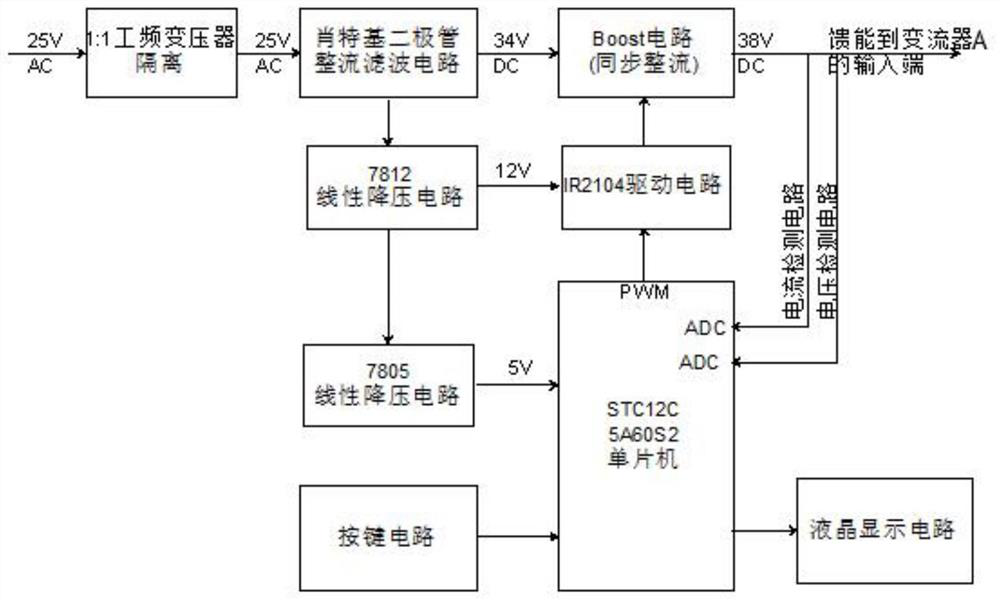

[0023] Specifically, the inverter part of the present invention adopts an open-loop design. After isolation wi...

Embodiment approach

[0036]Option 1: Hall current sensor. Current flows through the coil of the Hall sensor to generate a magnetic field. The magnetic field changes with the magnitude of the current. The magnetic field gathers in the magnetic ring, and the output voltage signal of the Hall element changes with the magnetic field. After detecting the voltage value, the magnitude of the current can be obtained.

[0037] Option 2: Resistor voltage divider detection circuit. By connecting the sampling resistor in series in the output circuit, the current passing through the resistor is converted into a voltage at both ends, and the current value is obtained by detecting the voltage value. The detection mode circuit and program control are relatively simple.

[0038] Converter A and converter B both include a system power supply circuit, a key circuit and a display circuit, the input end of the system power supply circuit of converter A is connected to the DC power supply, and the input end of the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com