Disposable medical surgical sterilization mask production process

A production process, one-off technology, applied in applications, special outerwear, biochemical fiber treatment, etc., can solve problems such as poor antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

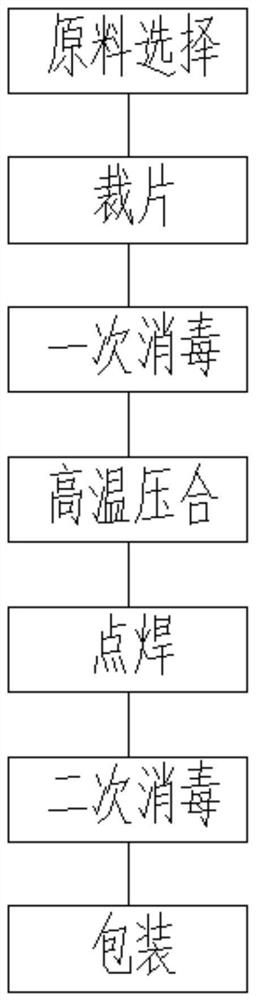

[0027] The production process of disposable medical surgical sterilized masks, through the steps of raw material selection, cutting, primary disinfection, high temperature pressing, spot welding, secondary disinfection and packaging, completes the production process of disposable medical surgical sterilized masks; the specific steps are as follows:

[0028] (1) Selection of raw materials: select the fabrics for making masks, which are non-woven surface layer, antibacterial fabric layer, melt-blown non-woven fabric layer and skin-friendly inner layer;

[0029] (2) Cutting pieces: place the non-woven surface layer, antibacterial fabric layer, melt-blown non-woven fabric layer and skin-friendly inner layer under the cutting machine in sequence, and cut according to the production size;

[0030] (3) One-time disinfection: transport the cut fabric to the disinfection area through the conveyor belt for one-time disinfection treatment;

[0031] (4) High-temperature pressing: The fabr...

Embodiment 2

[0046] The production process of disposable medical surgical sterilized masks, through the steps of raw material selection, cutting, primary disinfection, high temperature pressing, spot welding, secondary disinfection and packaging, completes the production process of disposable medical surgical sterilized masks; the specific steps are as follows:

[0047] (8) Raw material selection: select the fabrics for making masks, which are non-woven surface layer, antibacterial fabric layer, melt-blown non-woven fabric layer and skin-friendly inner layer;

[0048] (9) Cutting pieces: place the non-woven surface layer, antibacterial fabric layer, melt-blown non-woven fabric layer and skin-friendly inner layer under the cutting machine in sequence, and cut according to the production size;

[0049] (10) One-time disinfection: transport the cut fabric to the disinfection area through the conveyor belt for one-time disinfection treatment;

[0050] (11) High-temperature pressing: process th...

Embodiment 3

[0065] The production process of disposable medical surgical sterilized masks, through the steps of raw material selection, cutting, primary disinfection, high temperature pressing, spot welding, secondary disinfection and packaging, completes the production process of disposable medical surgical sterilized masks; the specific steps are as follows:

[0066] (15) Raw material selection: select the fabrics for making masks, which are non-woven surface layer, antibacterial fabric layer, melt-blown non-woven fabric layer and skin-friendly inner layer;

[0067] (16) Cutting pieces: place the non-woven surface layer, antibacterial fabric layer, melt-blown non-woven fabric layer and skin-friendly inner layer under the cutting machine in sequence, and cut according to the production size;

[0068] (17) One-time disinfection: transport the cut fabric to the disinfection area through the conveyor belt for one-time disinfection treatment;

[0069] (18) High-temperature pressing: process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com