Composite structure superhard material cutter capable of machining soft and hard metal

A composite structure and superhard material technology, applied in lathe tools, manufacturing tools, metal processing equipment, etc., can solve the problems of limiting the application of superhard material tools and limiting the application of superhard material tool processing technology, to achieve The effect of expanding the application field of superhard material cutting tools, saving tool changing time and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

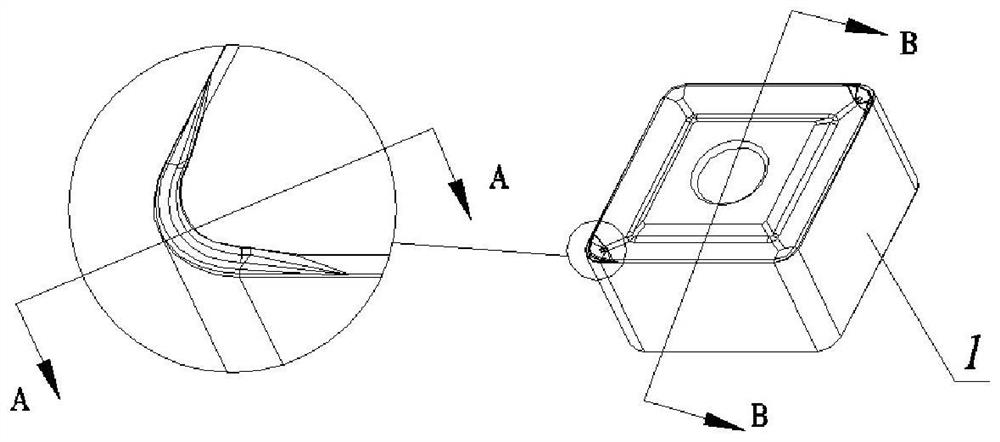

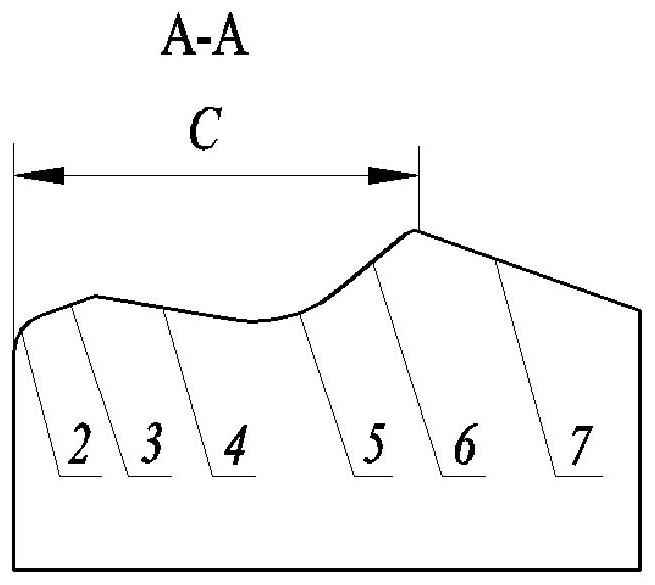

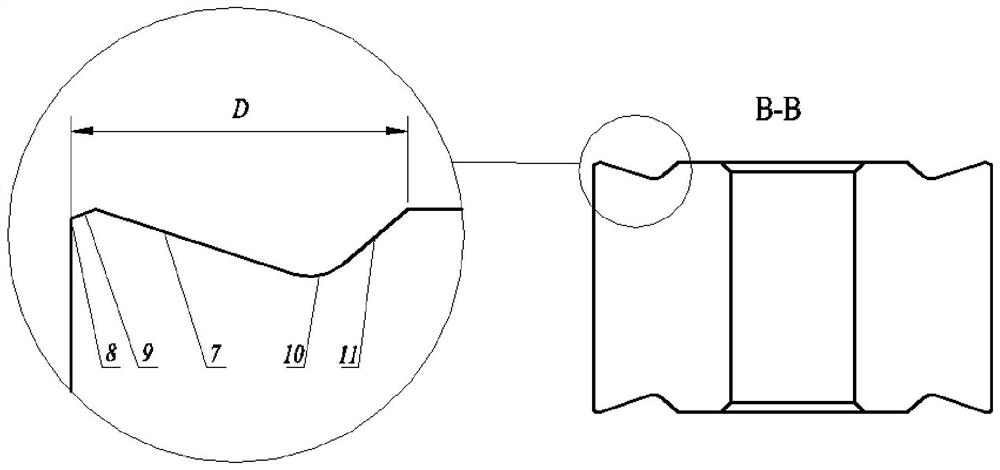

[0026] Please check Figure 1 to Figure 4 , a composite structure superhard material tool capable of processing soft and hard metals, including a superhard material blade 1, the blade 1 is provided with a large depth-of-cut groove D in an annular arrangement, and the cross-section of the bottom of the deep-cut groove includes sequentially connected from outside to inside The first cutting edge 8, the first negative chamfer 9, the first rake face 7, the first transition arc 10 and the first anti-chip surface 11; Small depth of cut groove C, the bottom cross section of the small depth of cut groove includes the second cutting edge 2, the second negative chamfer 3, the second rake face 4, and the second transition arc 5 sequentially connected from outside to inside And the second anti-chip surface 6, the second anti-chip surface 6 is connected with the second rake surface 7. The blade 1 includes a blade substrate 13 and a blade coating 12 coated on the blade substrate 13, the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com