A hand-automatic integrated flower basket silo transmission system and control method

A transmission system and integrated technology, which is applied in the field of manual and automatic flower basket silo transmission system and control, can solve problems such as affecting product quality, flower basket silo weight, instability, etc., so as to reduce the risk of production stagnation and improve stability. reliability and reliability, the effect of reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

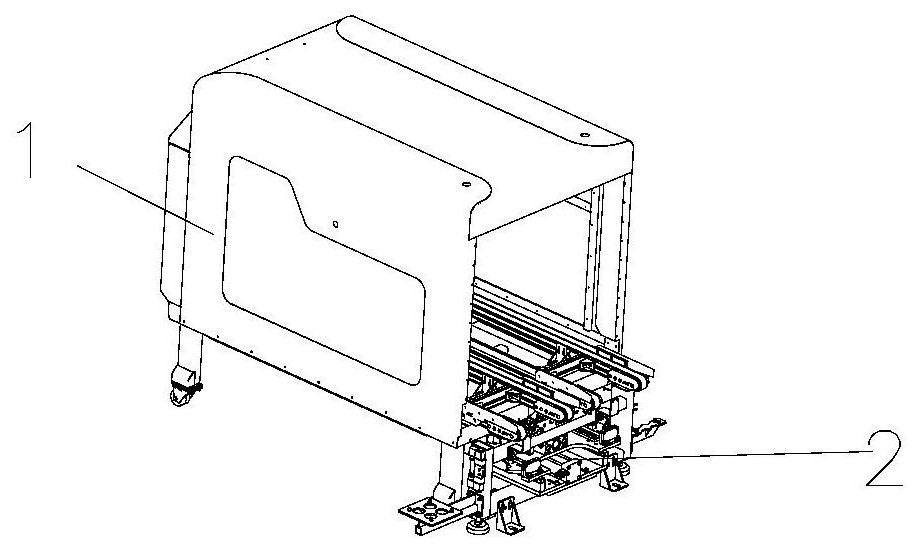

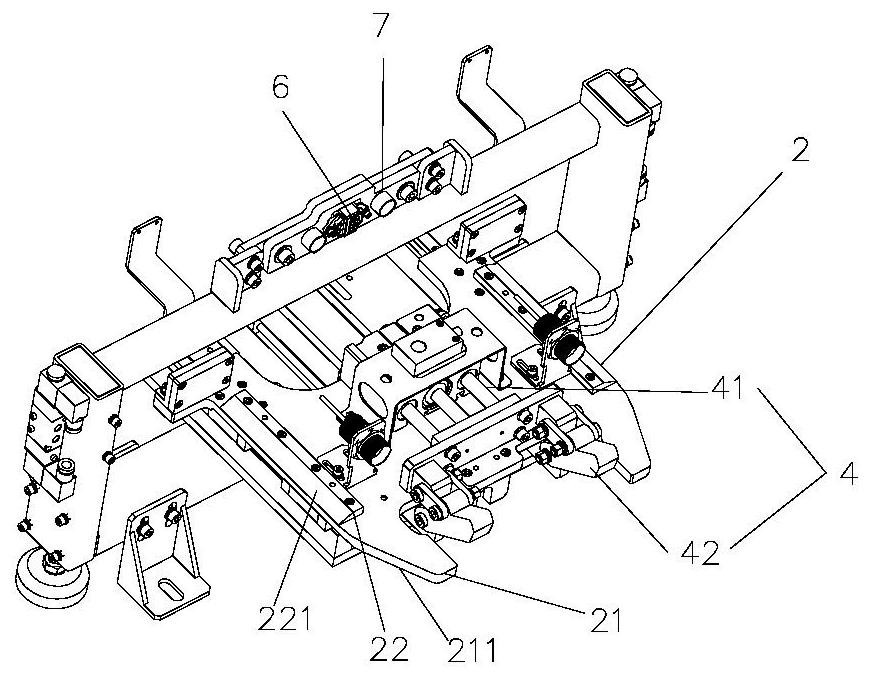

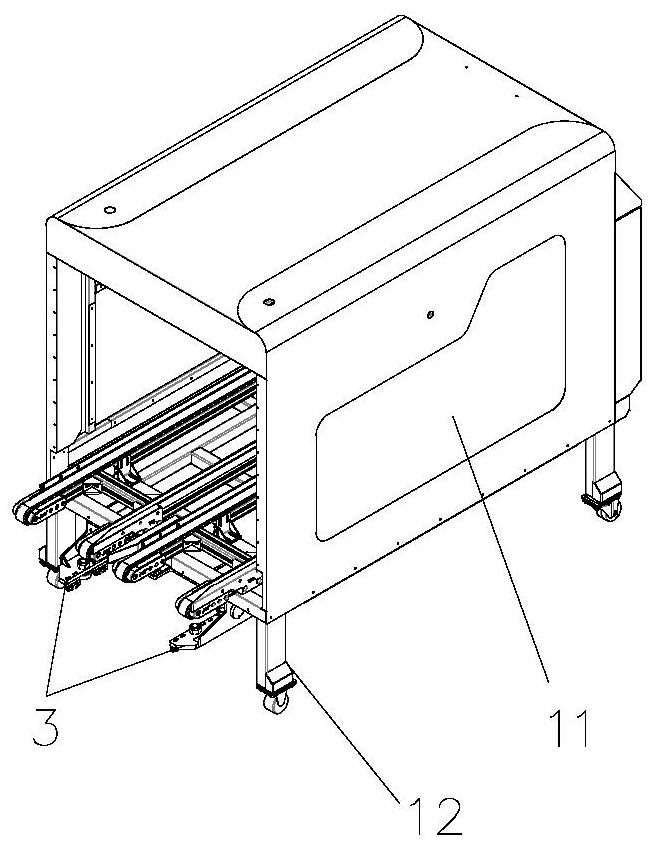

[0046] Such as Figure 1 to Figure 4 As shown, the present invention discloses a hand-automatic flower basket silo transmission system, which includes a silo 1 and a positioning mechanism 2 for positioning the silo. The silo 1 includes a box 11 for storing battery slices. The bottom of the box body 11 is provided with a bottom bracket 12 with a walking mechanism, and the bottom of the box body 11 is also provided with a symmetrically arranged roller guide mechanism 3. The roller guide mechanism 3 includes a guide bracket 31 arranged at the entrance and exit of the box body 11, several Horizontal guide roller 32 and some vertical guide rollers 33, horizontal guide roller 32 and vertical guide roller 33 are arranged on the guide support 31, and the central axis of horizontal guide roller 32 is perpendicular to the central axis of vertical guide roller 33; Positioning mechanism 2 comprises symmetrical Arranged guide plate 21, guide plate 21 cooperates with horizontal guide roller...

Embodiment 2

[0056] This embodiment provides a control method for a manual-automatic flower basket silo transmission system, including an automatic control mode and a manual control mode:

[0057] In the manual control mode, manually push the bin 1 close to the positioning mechanism 2, so that the roller guide mechanism 3 of the bin 1 is in contact with the guide plate 21 of the positioning mechanism 2 to realize the left and right positioning of the bin 1;

[0058] In the automatic control mode, the automatic transport mechanism 8 transports the bin 1 to the preset position, and controls the descent of the bin 1, so that the roller guide mechanism 3 of the bin 1 is in contact with the guide seat 22 of the positioning mechanism 2 to realize the left and right of the bin 1. position.

[0059] The control method of the transmission system in this embodiment includes two modes of manual control and automatic control, both of which can realize fast, accurate, stable and reliable positioning of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com