Lithium iron phosphate and production method and application thereof

A technology of lithium iron phosphate and its production method, which is applied in the direction of chemical instruments and methods, phosphorus compounds, electrochemical generators, etc., can solve the problems of low electronic conductivity and ion diffusion rate, charge and discharge performance attenuation, etc., and achieve low temperature performance improvement , The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

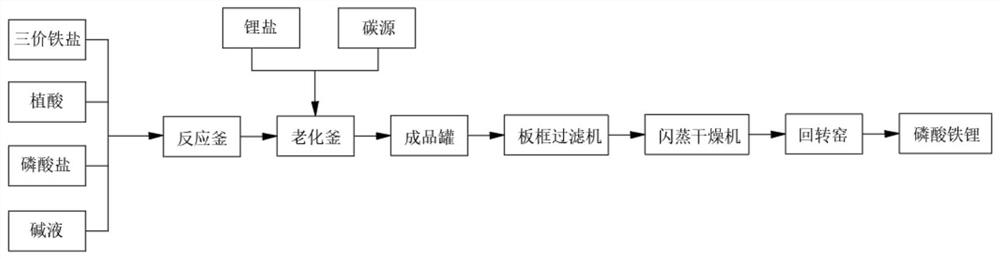

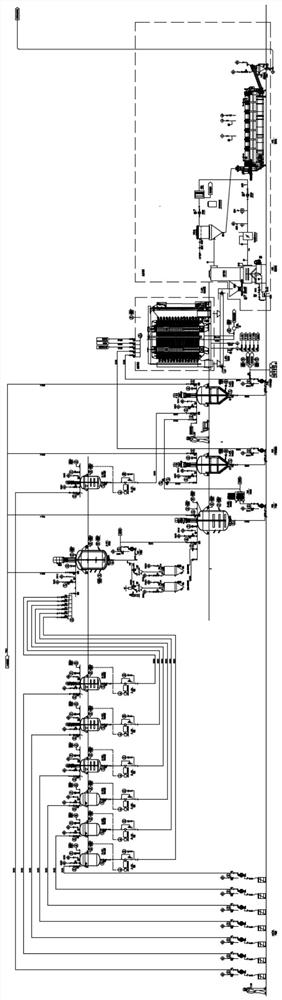

[0030] Such as Figure 1 to Figure 2 As shown, adopt the following steps to prepare lithium iron phosphate:

[0031] (1) ferric chloride solution, phytic acid, (NH 4 )H 2 PO 4 , Ammonia into the reactor, control phytic acid and (NH 4 )H 2 PO 4 The molar ratio is 1:99, and the pH value of the system is adjusted to about 2 by controlling the amount of ammonia water added, and then mixed and stirred in the reaction kettle at room temperature for 1 hour; then the reaction slurry is pumped into the aging kettle for aging for 1 hour to obtain Iron phosphate precursor fluid.

[0032] (2) Lithium carbonate and glucose are added into the aging kettle to fully mix and disperse with the ferric phosphate precursor body liquid, and the obtained mixed slurry is pumped into the finished product tank for temporary storage; then the mixed slurry is pumped into a plate and frame filter for filtration, and then The wet material is added to the flash dryer for flash drying, and then added ...

Embodiment 2

[0034] Such as Figure 1 to Figure 2 As shown, adopt the following steps to prepare lithium iron phosphate:

[0035] (1) ferric chloride solution, phytic acid, H 3 PO 4 , Ammonia into the reactor, control phytic acid and H 3 PO 4 The molar ratio is 1:99, and the pH value of the system is adjusted to about 2 by controlling the amount of ammonia water added, and then mixed and stirred in the reaction kettle at room temperature for 1 hour; then the reaction slurry is pumped into the aging kettle for aging for 1 hour to obtain Iron phosphate precursor fluid.

[0036] (2) Lithium carbonate and glucose are added into the aging kettle to fully mix and disperse with the ferric phosphate precursor body liquid, and the obtained mixed slurry is pumped into the finished product tank for temporary storage; then the mixed slurry is pumped into a plate and frame filter for filtration, and then The wet material is added to the flash dryer for flash drying, and then added to the rotary ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com