Aluminum-based diamond composite material with high smoothness and preparation method thereof

A technology with high smoothness and composite materials, which is applied in the field of diamond-containing alloys, can solve the problems of poor surface finish, difficult control of composite materials, and difficulty in ensuring the strength of composite materials. It achieves low thermal expansion, uniform distribution of diamonds, and adjustable thickness. tune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

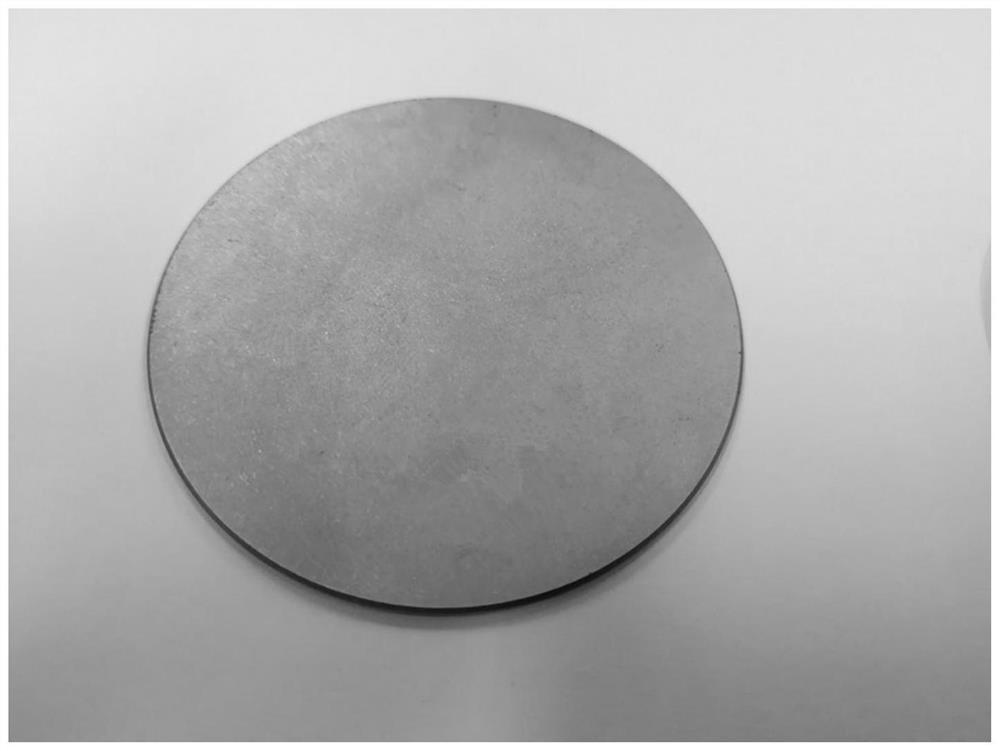

[0040] An aluminum-based diamond composite material with high smoothness, the specific preparation method is as follows:

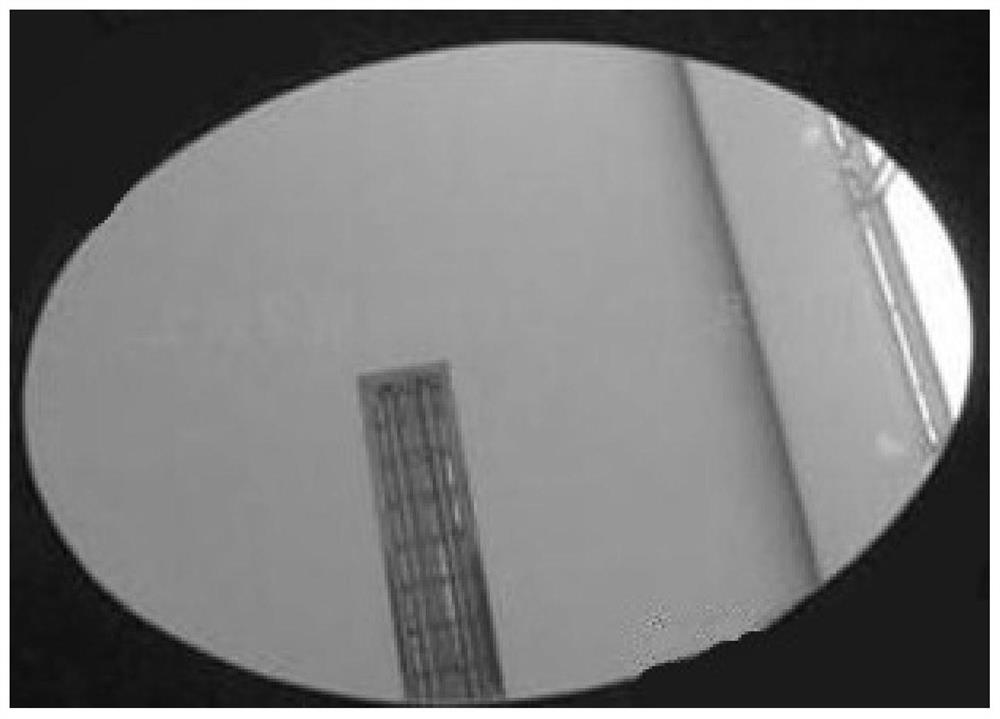

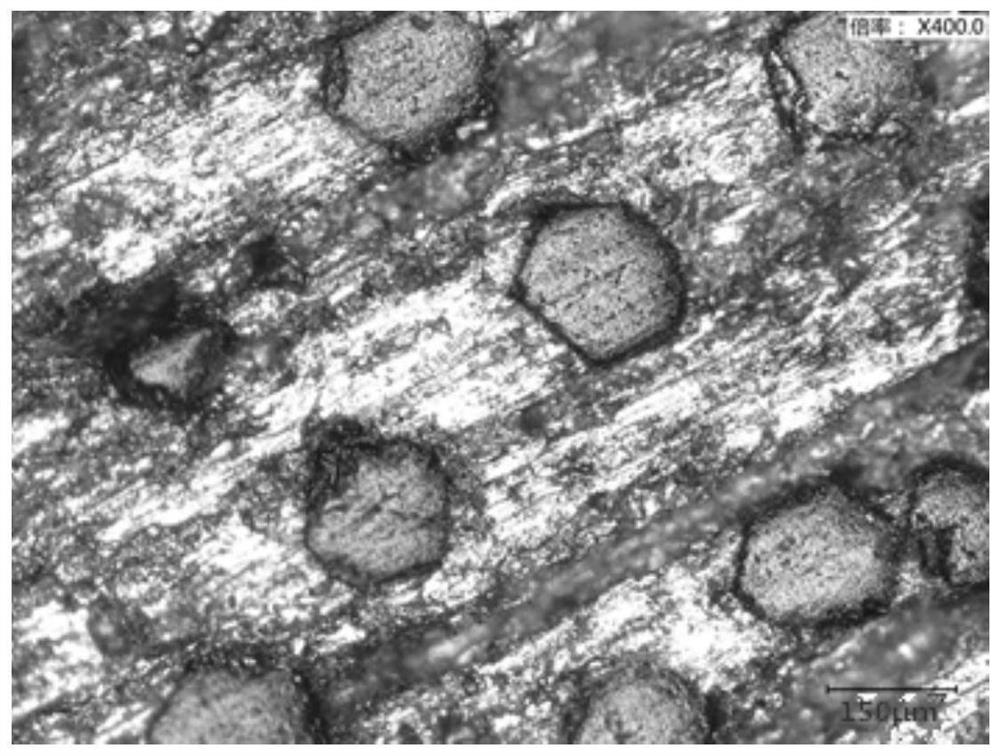

[0041] 1) Mix aluminum powder (average particle size 85 μm) and kerosene at a mass ratio of 100:5, and use a coating machine to make aluminum powder flakes with a thickness of 0.2 mm; use the diamond distribution machine of YOFC Co., Ltd. (patent No.: CN213439170U) SiC-Si coated diamond particles (particle size 300 μm, coating thickness 0.3 μm) are evenly arranged in an array on the surface of the aluminum powder sheet at 200 μm equal intervals, to obtain an aluminum-diamond composite sheet with diamond particles arranged on the surface A;

[0042] 2) Metal AlSi 12 Pre-alloyed powder (average particle size 68μm) and kerosene are mixed evenly at a mass ratio of 100:3, and made into 0.2

[0043] ㎜ thick aluminum-silicon alloy powder flake B;

[0044] 3) 5 layers of the above-mentioned aluminum-silicon alloy powder flakes B are superimposed as the upper an...

Embodiment 2

[0060] A kind of aluminum base diamond composite material with high smoothness, its preparation method is as follows:

[0061] 1) Mix aluminum powder (average particle size 50 μm) and kerosene evenly at a mass ratio of 100:5, and use a coating machine to make a 0.1 mm thick aluminum powder sheet; -Ti-coated diamond particles (particle size 150 μm, coating thickness 0.2 μm) are uniformly arranged in an array on the surface of the aluminum powder sheet at equal intervals of 150 μm, and an aluminum-diamond composite sheet A with diamond particles arranged on the surface is obtained;

[0062] 2) Metal AlSi 10 Mg pre-alloyed powder (average particle size 56μm) and kerosene mass ratio 100:3 are evenly mixed, and a 0.1mm thick aluminum-silicon alloy powder flake B is made into the upper and lower surface layers by a coating machine;

[0063] 3) The above-mentioned 5-layer aluminum-silicon alloy powder sheet B is superimposed as the upper and lower surface layers, and the 6-layer alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com