Variable-rigidity vibration isolation device for punching machine

A technology of rigidity and punching, which is applied in the field of machine tool equipment, can solve the problems of reduced machining accuracy, lack of shock absorption effect, and influence on machine tool stability, etc., and achieve good vibration reduction effect, small vibration amplitude, and high machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

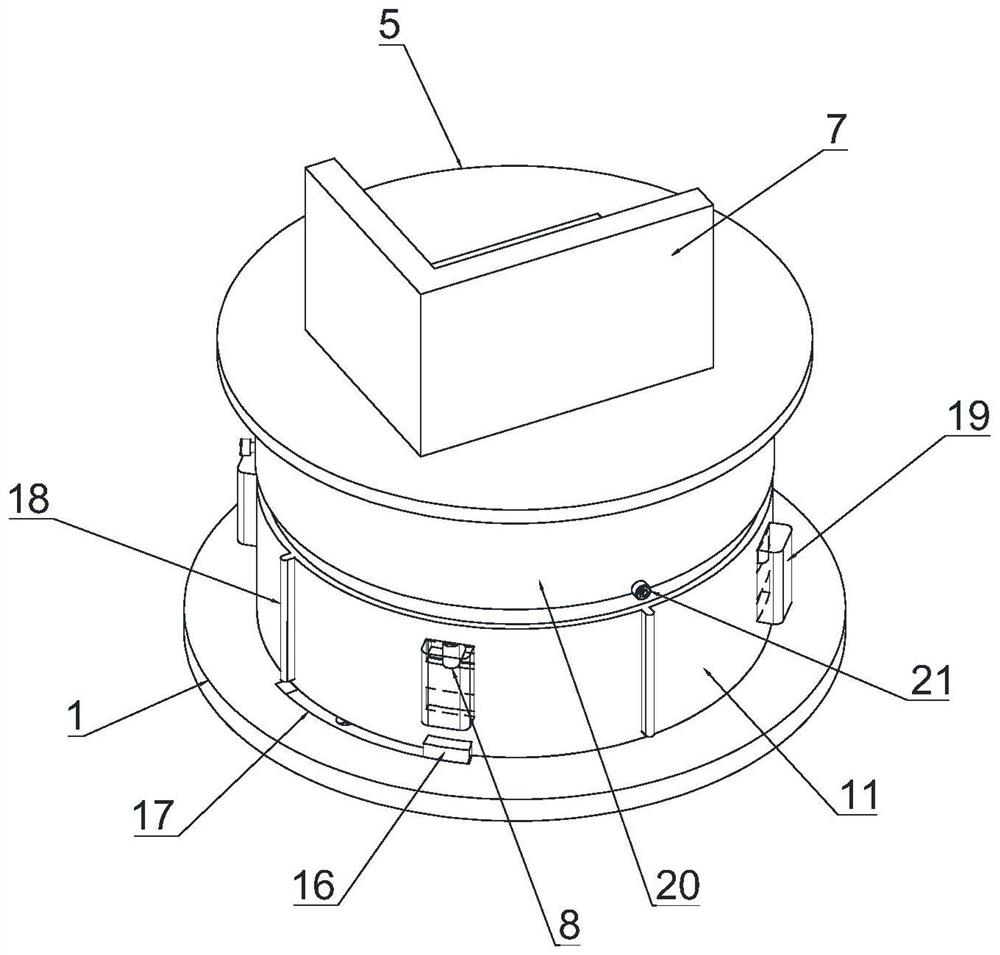

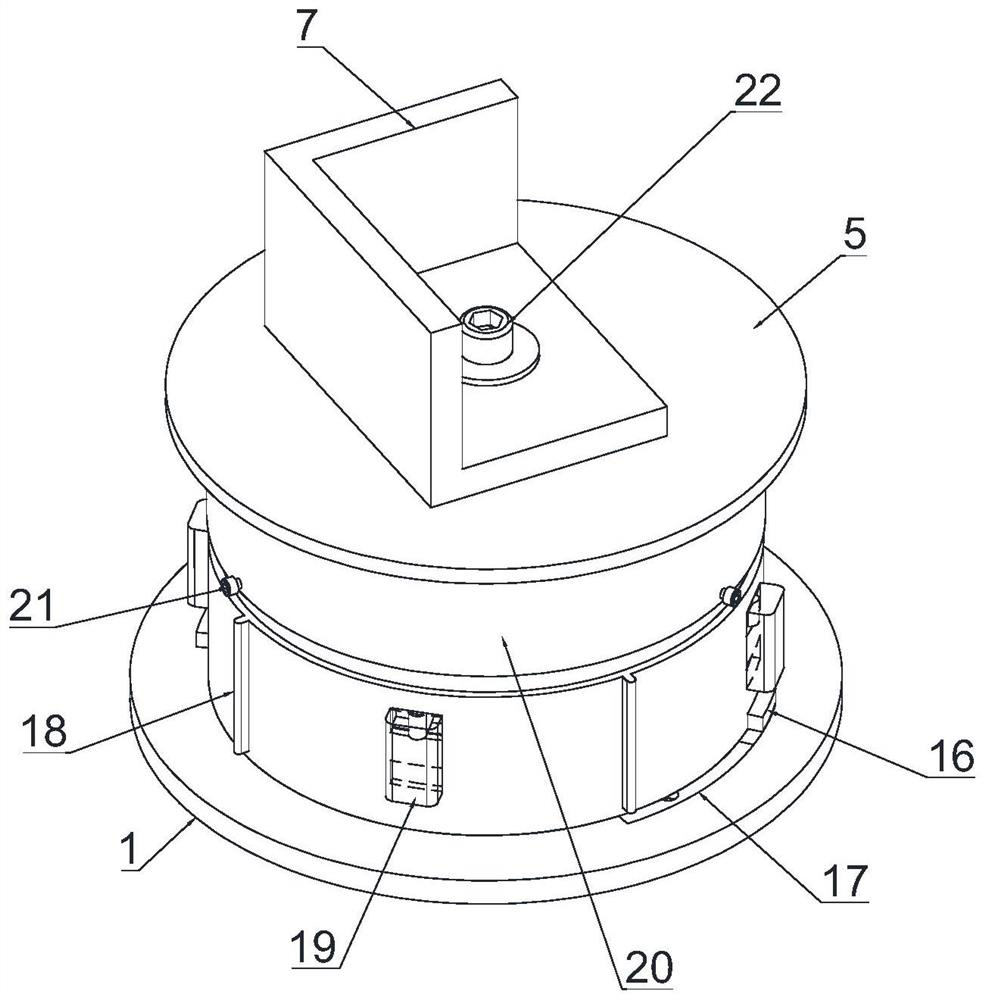

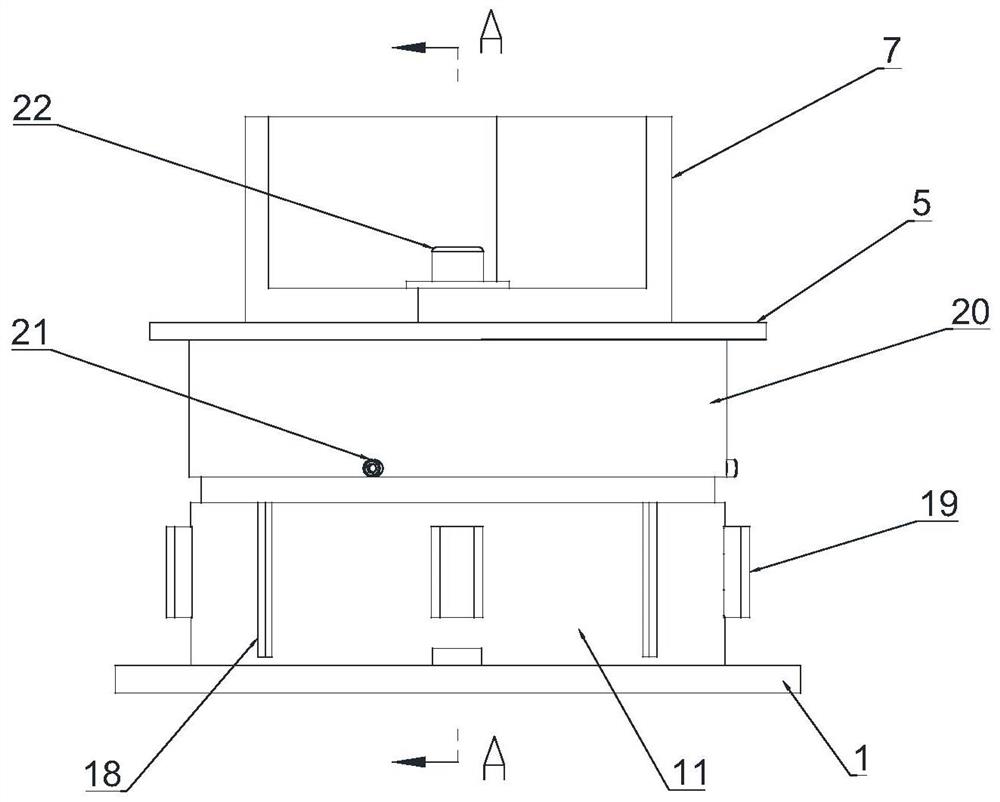

[0036] see Figure 1-Figure 4 , this embodiment discloses a punch press vibration isolation device with variable stiffness, including a base 1, a cylinder 2, a guide cylinder 3, a pressure plate 4, a support plate 5, eight disc reeds 6 and a disc reed for adjusting 6 working quantity adjustment mechanism; the lower end of the cylinder 2 and the guide cylinder 3 are fixedly connected to the base 1, the guide cylinder 3 is located inside the cylinder 2 and coaxially arranged with the cylinder 2; The pressure plate 4 is arranged between the support plate 5 and the guide cylinder 3, the upper end of the pressure plate 4 is connected with the support plate 5, and the lower end is slidingly connected with the outer wall of the guide cylinder 3; the machine foot 7 of the machine tool is set On the support plate 5, the machine foot 7, the support plate 5 and the pressure plate 4 are fixedly connected by bolts 22 between the machine foot 7 and the pressure plate 4; eight disc springs 6...

Embodiment 2

[0055] Other structures in this embodiment are the same as in Embodiment 1, the difference is that the sliding sleeve 20 and the pressure plate 4 are integrally structured, and the advantage is that the sliding sleeve 20 and the pressure plate 4 can slide up and down stability, thereby improving the stability of the machine foot 7.

Embodiment 3

[0057] Other structures in this embodiment are the same as in Embodiment 1, except that the number of disc springs 6 can be other numbers, such as nine, and each area is divided into three evenly. The thickness of each disc spring 6 can be different from each other, and the thickness of the disc springs 6 in each region can also be different from each other; the advantage can make the disc spring 6 have better rigidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com