Multifunctional intelligent detection and diagnosis integrated equipment for automobile chassis

An automotive chassis and intelligent detection technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of low work efficiency, cannot become a car chassis, and outdated detection technology, so as to improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

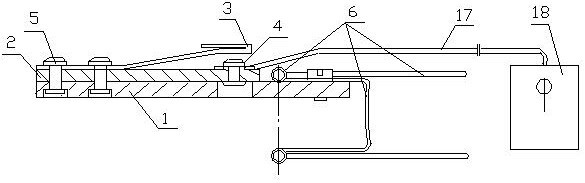

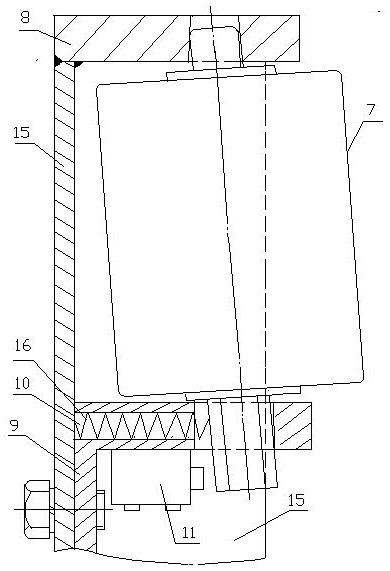

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

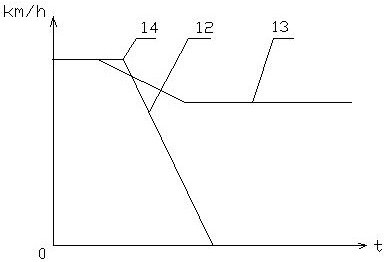

[0020] 1. First, solve the existing problems of the inertial table: 1. The serious noise of high-speed detection is caused by the use of sleeve roller chain transmission. The sprocket speed exceeds 1500rpm, which will produce harsh noise similar to air defense alarm. The higher the speed, the more noise Large, the present invention replaces the sleeve roller chain with a toothed chain (silent chain) and the noise is very small; 2. It is difficult to drive the vehicle body upright, but in high-speed detection, as long as the longitudinal axis of the vehicle body and the longitudinal axis of the detection equipment If the axes are not parallel, it is easy to cause the wheel to slide sideways on the high-speed rotating drum. The more inclined the swing car or the higher the rotation speed, the greater the speed and inertia of the sideways slide, which makes the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com