Method for constructing coal mine transparent working surface by using borehole radar

A technology of drilling radar and working face, which is applied in the field of geophysical exploration, can solve the problems of difficult instrument development and lack of attention, and achieve the effects of fast data processing and interpretation, fast construction, and short drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

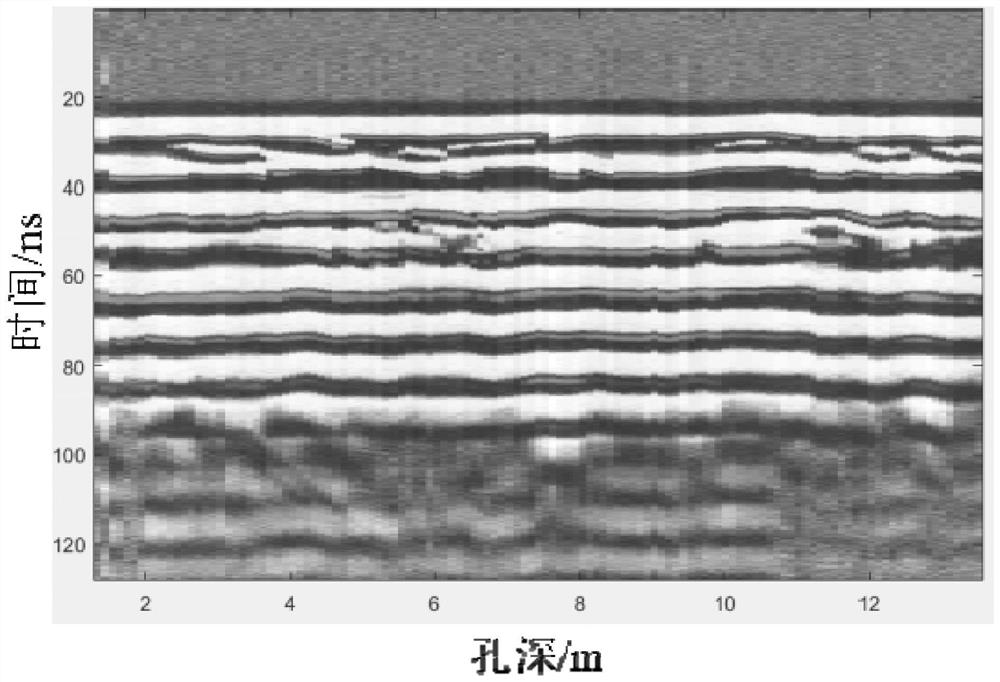

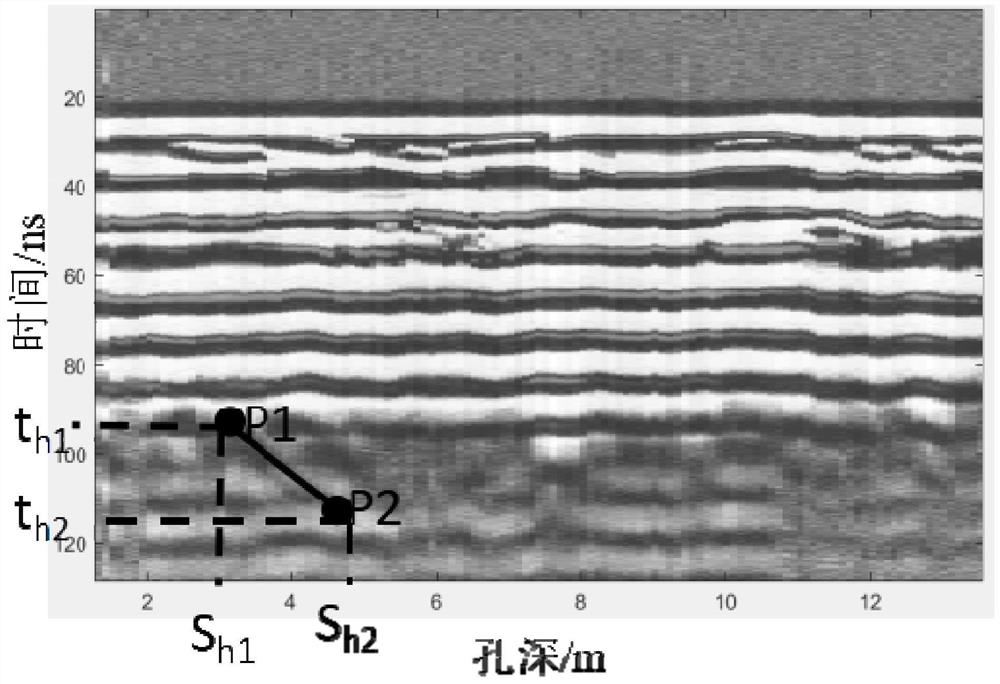

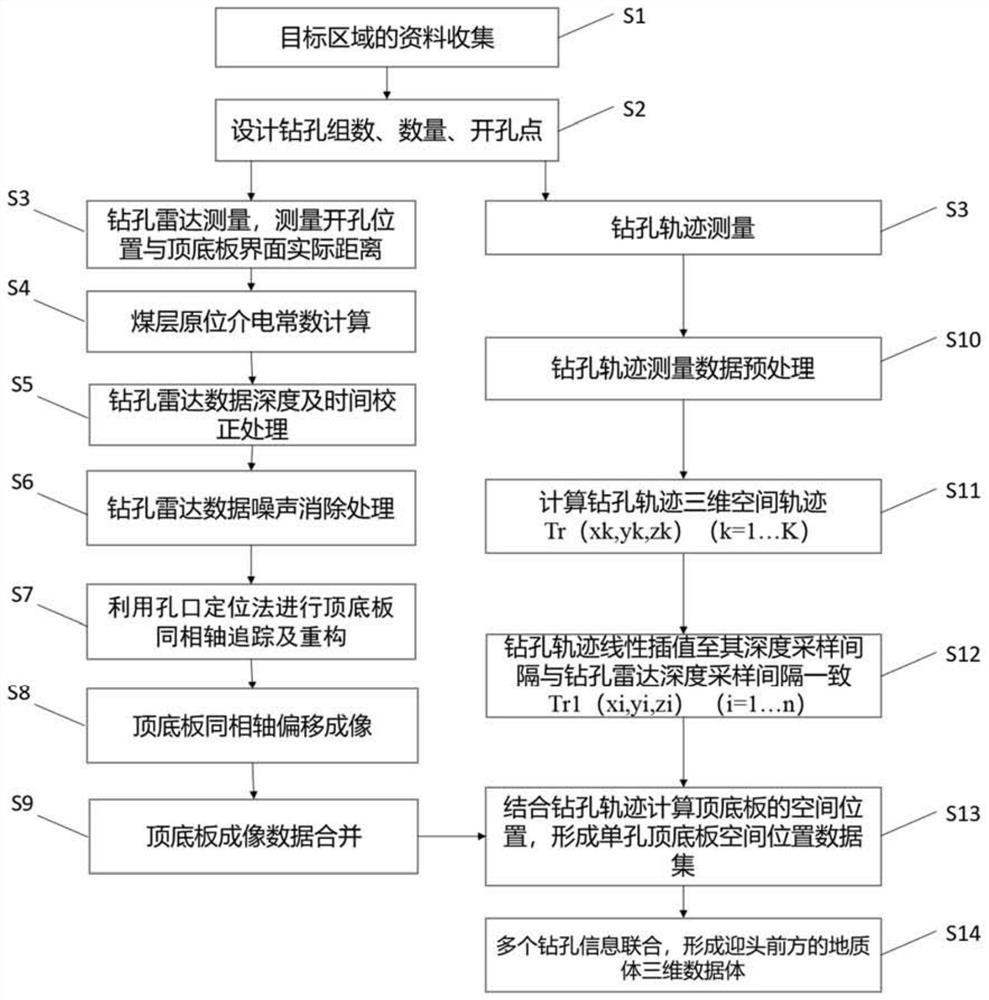

[0049] This embodiment provides a method of using borehole radar to construct a transparent working face in a coal mine, such as figure 1 As shown, the method includes the following steps:

[0050] Step S1, data collection of the target area:

[0051] Collect data on the mining area and the mining face, which includes the length L of the mining face k , the width of the mining face W k , the height H of the mining face k and mining coal seam thickness H c ;

[0052] The plan of the mining face is as follows: figure 2 As shown, the section diagram of the mining working face is shown in image 3 shown.

[0053] Step S2, designing the number, quantity and opening points of drilling groups;

[0054] The length of each borehole is l s , in order to ensure the rapid construction of geological bodies during mining, l s Requirements to meet 10ms z , N z Satisfy the following formula:

[0055] N z = L k / l s ;

[0056] According to the width W of the mining face k , e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com