Isolated temperature sensing for electrical terminals

A technology of electrical terminals and electrical isolation, applied in the direction of thermometers, thermometers, and thermometers with physical/chemical changes that are directly sensitive to heat, electric/magnetic components, etc., can solve the problem of pin cross-sectional area reduction and ohmic heating increase , resistance increase and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

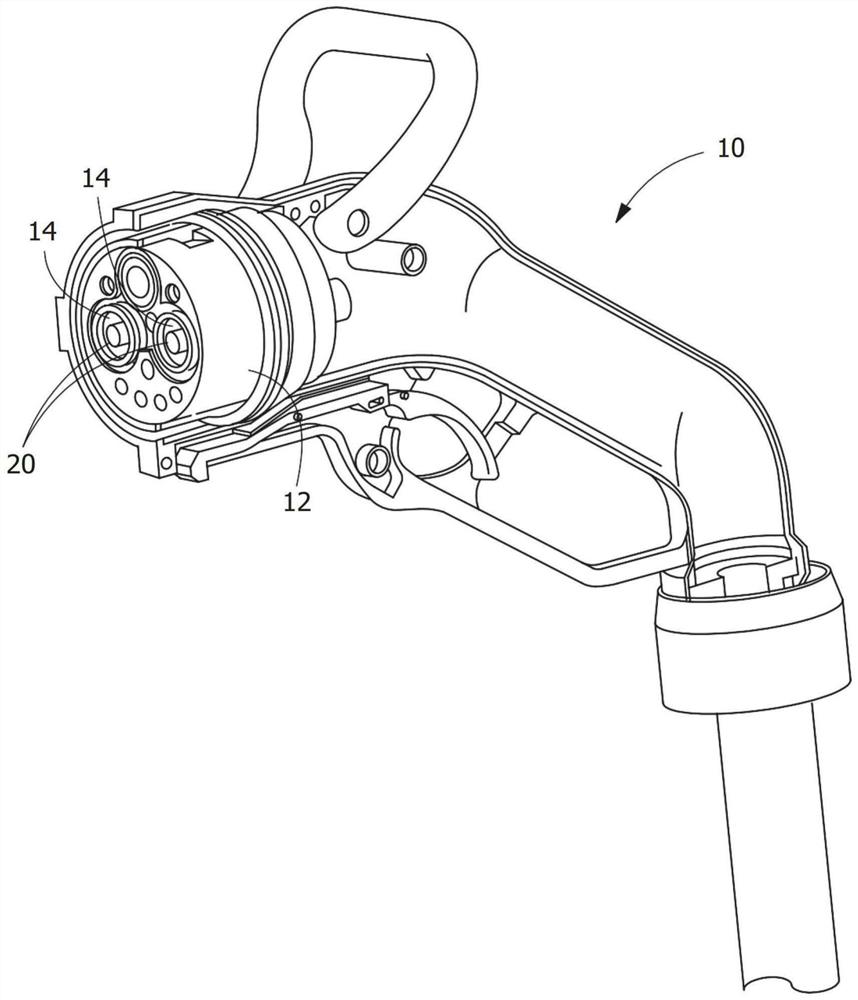

[0016] refer to figure 1 , shows a representative charging port connector 10 incorporating electrical terminals 20 and an isolated temperature sensing system, as will be described more fully, for sensing the temperature of electrical terminals 20 . The connector 10 has a housing 12 in which a terminal accommodating chamber 14 is disposed. The terminal accommodating cavity 14 is configured to accommodate the terminal 20 therein. The specific configuration and shape of the connectors may vary without departing from the scope of the present invention.

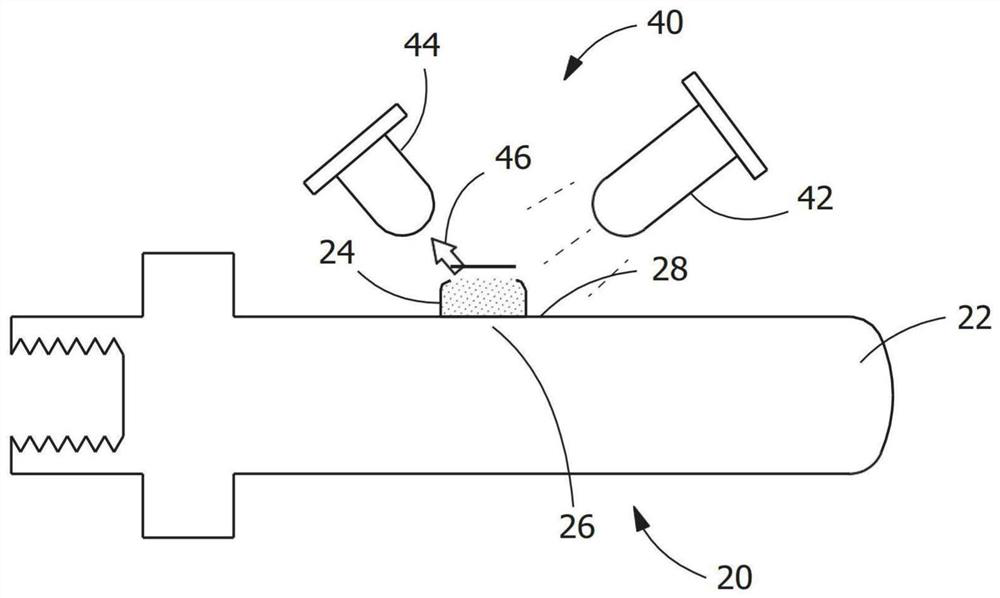

[0017] exist figure 2 In the illustrative embodiment shown, terminal 20 is in the shape of a pin having a free end 22 configured to mate with a mating connector (not shown) provided in a vehicle or the like. The size and shape of the terminal 20 can vary depending on the application and the amount of current that the terminal 20 must carry.

[0018] A sheet of material 24 is applied to a region 26 of each terminal 20 . The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com