Efficient column chromatography system

A chromatography system and high-efficiency column technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems that column chromatography equipment cannot realize automatic operation, low purity and poor stability of the obtained products, etc. Achieve the effects of saving labor costs and time costs, avoiding manual replacement of chromatography columns, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

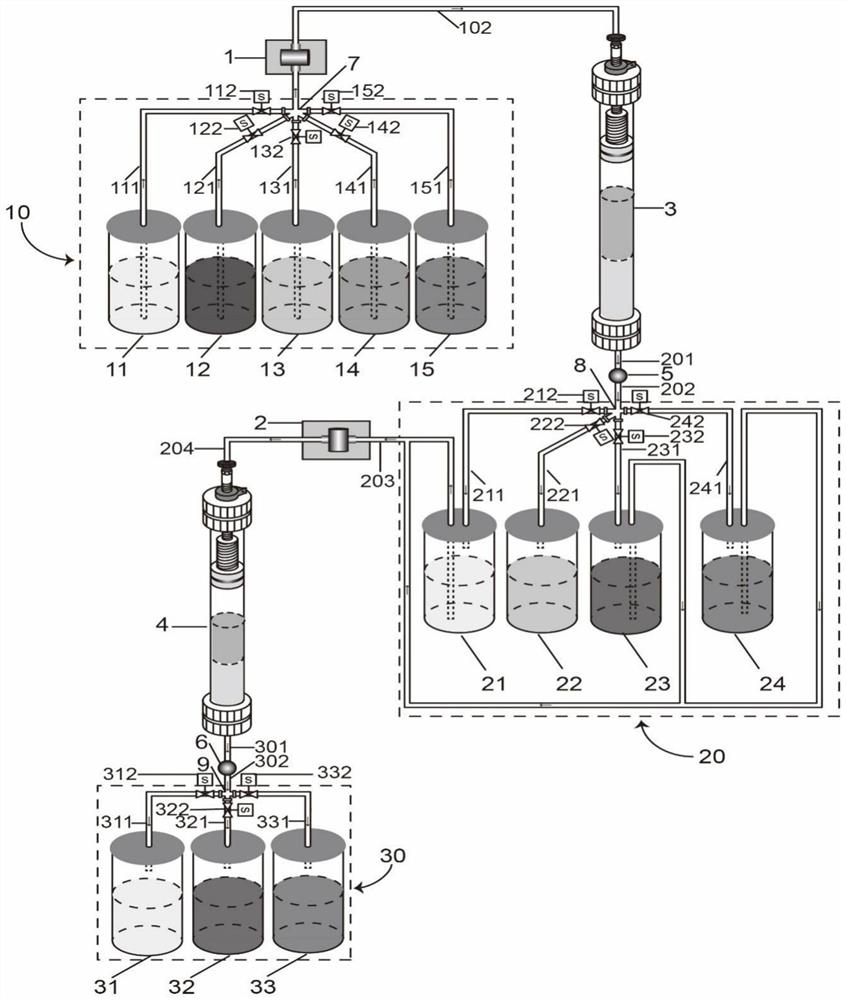

[0053] Embodiment 1 High-efficiency column chromatography system structure and operation mode

[0054] as attached figure 1 As shown, a high-efficiency column chromatography system of the present invention is mainly composed of a chromatography column 3, a deacidification column 4, a liquid storage unit 10, a temporary storage unit 20, and a collection unit 30. The liquid storage unit 10 passes through the first high-pressure The constant flow pump inlet pipe 101 communicates with the first high-pressure constant-flow pump 1, and the first high-pressure constant-flow pump 1 communicates with the chromatography column 3 through the first high-pressure constant-flow pump outlet pipe 102, and the chromatography column 3 passes through the first online The detector liquid inlet pipe 201 communicates with the first online detector 5, and the first online detector 5 communicates with the temporary storage unit 20 through the first online detector liquid outlet pipe 202, and the temp...

Embodiment 2

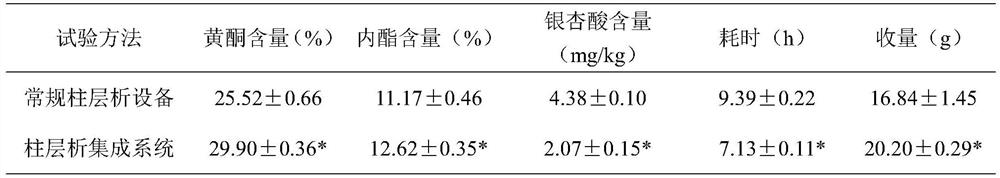

[0062] Example 2 The research on the purification of Ginkgo biloba extract by column chromatography integrated system

[0063] 1 material

[0064]Ginkgo biloba extract was provided by Lunan Houpu Pharmaceutical Co., Ltd. Drug Research and Development Center (Ginkgo biloba was purchased from Shandong Tancheng Shengqiang Ginkgo Co., Ltd.); LX-158 and LX-02 macroporous resins (Xi’an Lanxiao Technology New Materials Co., Ltd. ); 36×920mm protein compression column and 200mL microfluidic reactor pump (Shanghai Saifanke Separation Technology Co., Ltd.).

[0065] 2 methods

[0066] 2.1 Purification of Ginkgo biloba extract by conventional column chromatography equipment

[0067] Column packing: Take a clean protein compression column and pack it tightly and evenly with LX-158 macroporous resin (column volume is about 540mL), (this step can be omitted for regenerating the chromatography column).

[0068] Column flushing: set the pump flow rate of the microflow reactor to 35mL / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com