Material detection alarm device for pyrolytic carbon black screening and drying process

A material detection and alarm device technology, applied in the direction of alarm, filter screen, solid separation, etc., can solve the problem that the performance indicators of pyrolysis primary carbon black cannot meet the industrial application requirements, pollute the production site and the surrounding environment, and restrict the development of enterprises, etc. problems, to achieve the effect of improving adjustability, timely warning and alarming, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

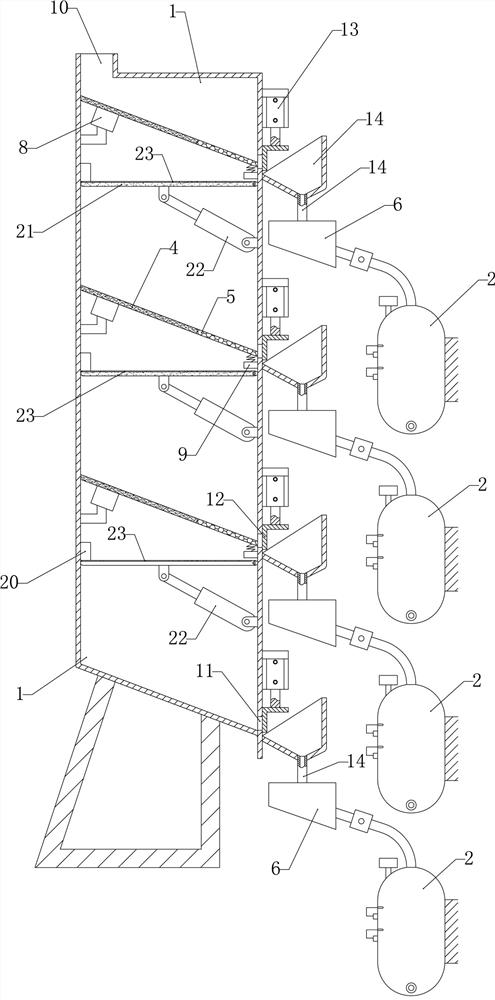

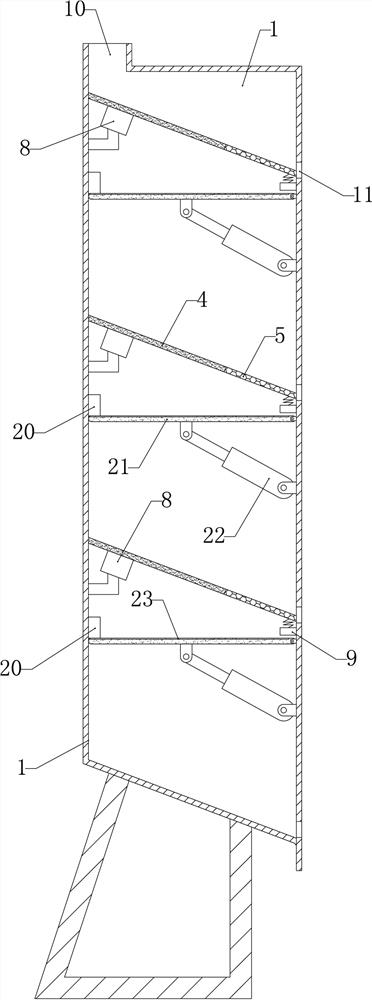

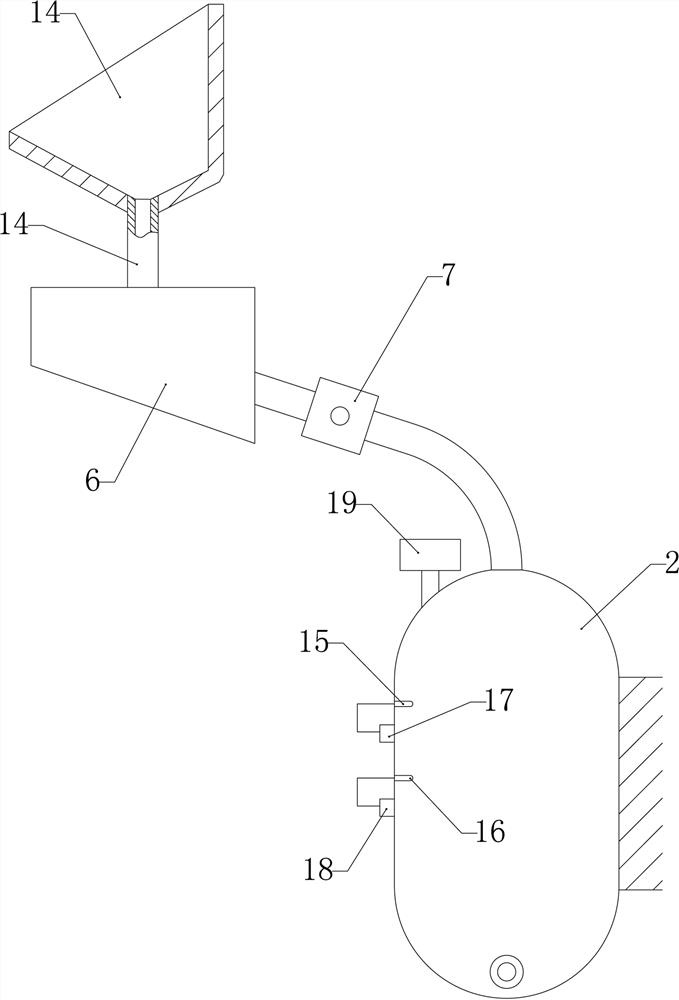

[0028] The material detection and alarm device for pyrolytic carbon black sieving and drying process includes two fixed cubic tubes 1, and several sieves are arranged at intervals from top to bottom on the side wall of the inner cavity of the cubic tube 1. Material mechanism, a pretreatment mechanism is respectively installed between adjacent sieving material mechanisms, and each described sieving material mechanism is used to cooperate to realize the multistage screening of pyrolysis carbon black material, at the lower end of each described sieving material mechanism One side is respectively connected with a comparison reaction tank 2, each of the comparison reaction tanks 2 is arranged on the outside of the cubic tube 1, and a reaction detection alarm unit is installed on each of the comparison reaction tanks 2, each of the reaction The detection and alarm units are respectively used to detect the reaction state in the corresponding contrast reaction tank 2 and realize the al...

Embodiment 2

[0048] The material detection and alarm device for pyrolytic carbon black sieving and drying process includes two fixed cubic tubes 1, and several sieves are arranged at intervals from top to bottom on the side wall of the inner cavity of the cubic tube 1. material mechanism, a pretreatment mechanism is respectively installed between the adjacent sieve material mechanisms, each of the sieve material mechanisms is used to cooperate to realize the multi-stage screening of pyrolysis carbon black materials, at the lower end of each of the sieve material mechanisms One side is respectively connected with a comparison reaction tank 2, each of the comparison reaction tanks 2 is arranged on the outside of the cubic tube 1, and a reaction detection alarm unit is installed on each of the comparison reaction tanks 2, each of the reaction The detection and alarm units are respectively used to detect the reaction state in the corresponding contrast reaction tank 2 and realize the alarm; on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com