System and method for preventing irregular rolled material throwing output

An irregular and transmission system technology, applied in the direction of guiding/positioning/alignment devices, etc., can solve problems such as mechanical performance finished product indicators, finished product appearance, abnormal noise of supporting reducer, etc., to achieve overall ductility and Precise control, improving the quality of finished products and comprehensive quality, and improving the effect of precise delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

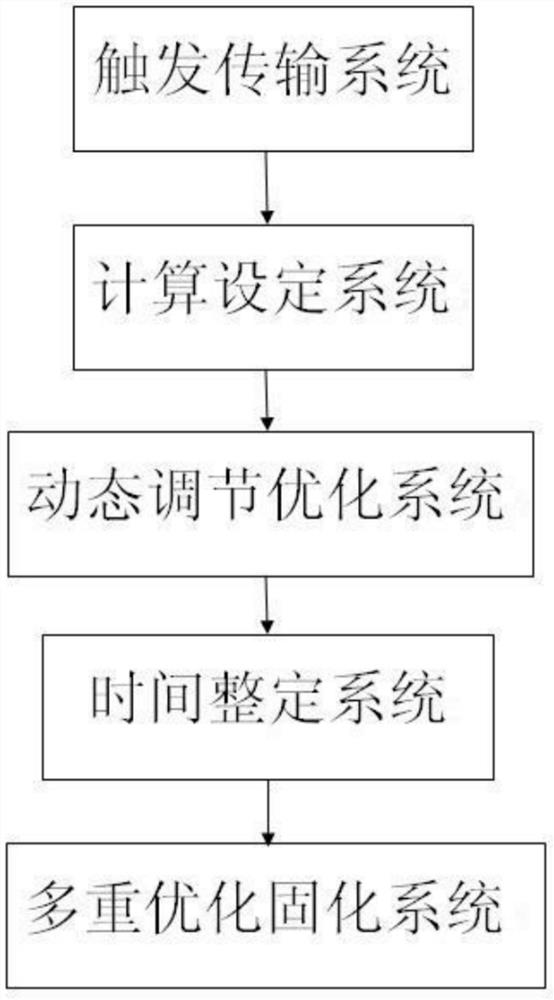

[0029] according to figure 1As shown, this embodiment proposes a system for preventing irregular output of rolled materials, including a trigger transmission system, a calculation setting system, a dynamic adjustment optimization system, a time setting system, and a multiple optimization curing system. The trigger transmission system It is used to collect the steel signal of the digital quantity of the detector of the horizontal looper before the finishing rolling, and then transmit it to the first transmission frame after the finishing rolling after the signal trigger and the steel passing delay in the fixed area; the calculation setting system is in the finishing rolling After the first transmission stand receives the signal, first remove the speed lead rate based on the finishing rolling group, and then set the rear lag rate of the first transmission stand after finishing rolling to a negative number, the absolute value of which is based on the finishing rolling group speed...

Embodiment 2

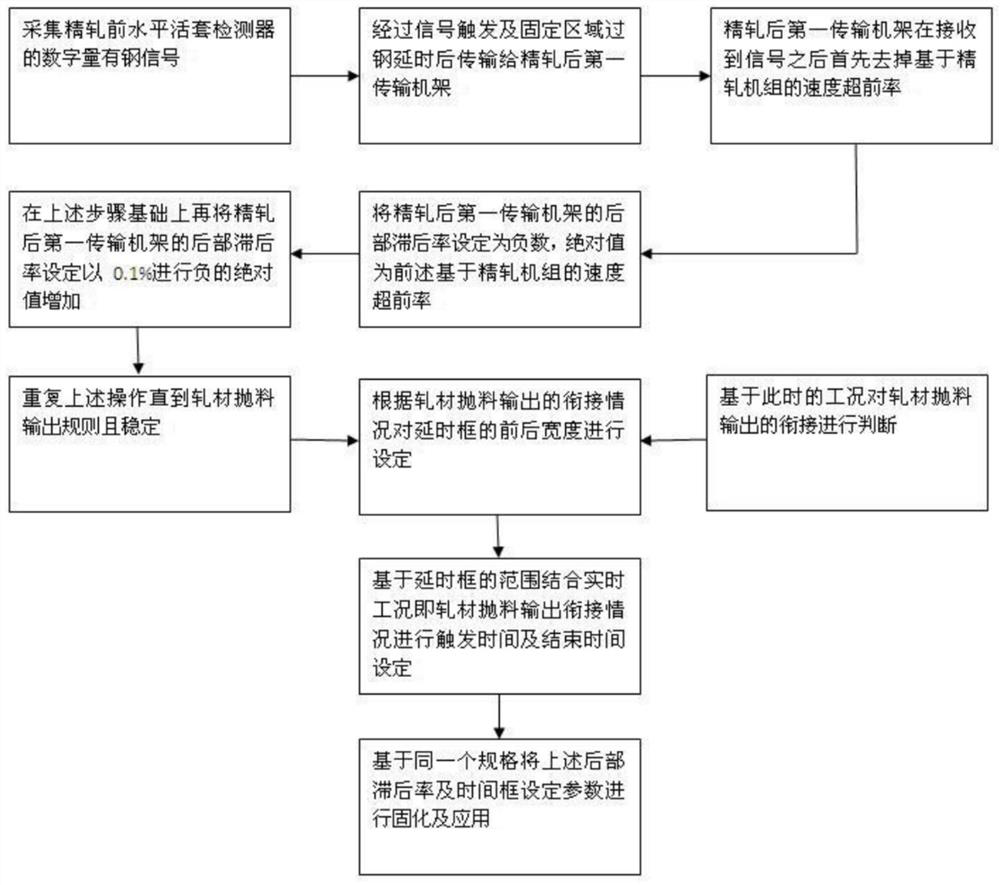

[0037] according to figure 2 As shown, the present embodiment proposes a method for preventing irregular output of rolled material throwing, including the following steps:

[0038] Step 1: Start the trigger transmission system, collect the digital steel signal of the detector of the horizontal looper before finishing rolling, and transmit it to the first transmission rack after finishing rolling after signal triggering and steel passing delay in the fixed area;

[0039] Step 2: After receiving the signal, the first transmission rack after finishing rolling starts the calculation and setting system, removes the speed advance rate based on the finishing rolling unit, and sets the rear lag rate of the first transmission rack after finishing rolling as Negative number, the absolute value is the aforementioned speed lead rate based on the finishing mill;

[0040] Step 3: Start the dynamic adjustment and optimization system. On the basis of the above steps, set the rear hysteresis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com