Manganin shunt welding device with rapid cooling function

A manganese-copper shunt and rapid cooling technology, which is applied to auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of large size, inconvenient operation, and low efficiency of welding manganese-copper shunts, so as to improve processing efficiency and facilitate Effect of cooling and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

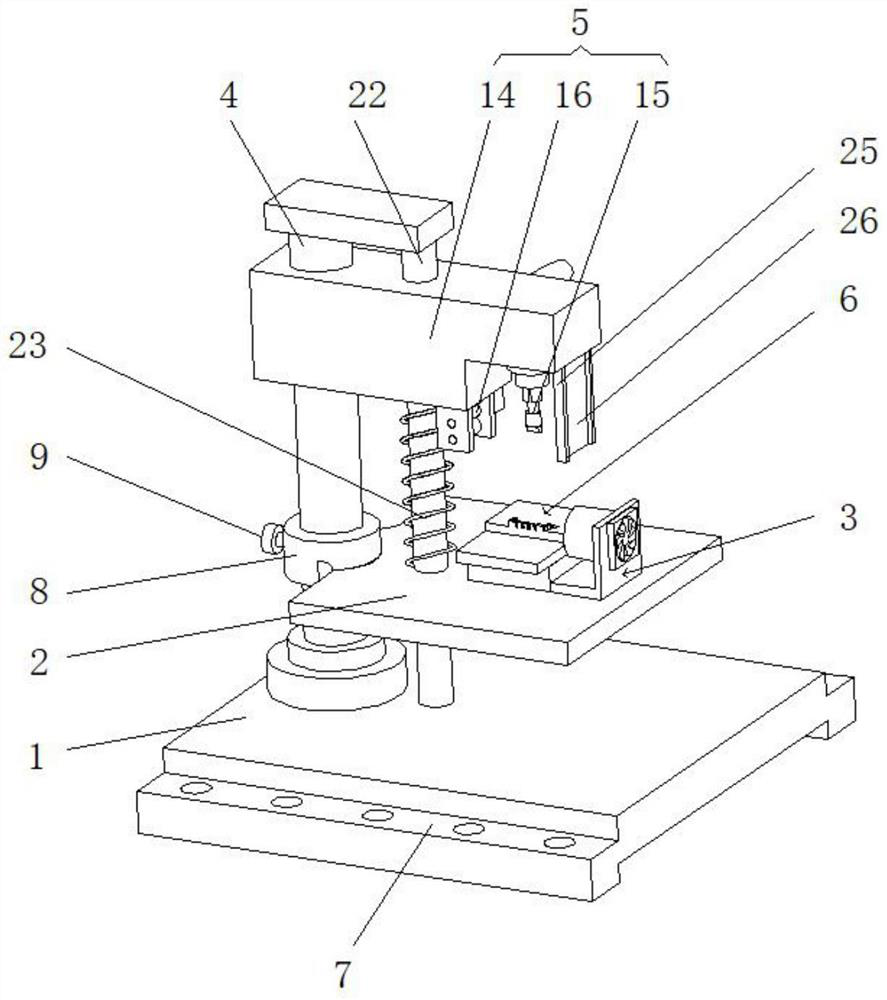

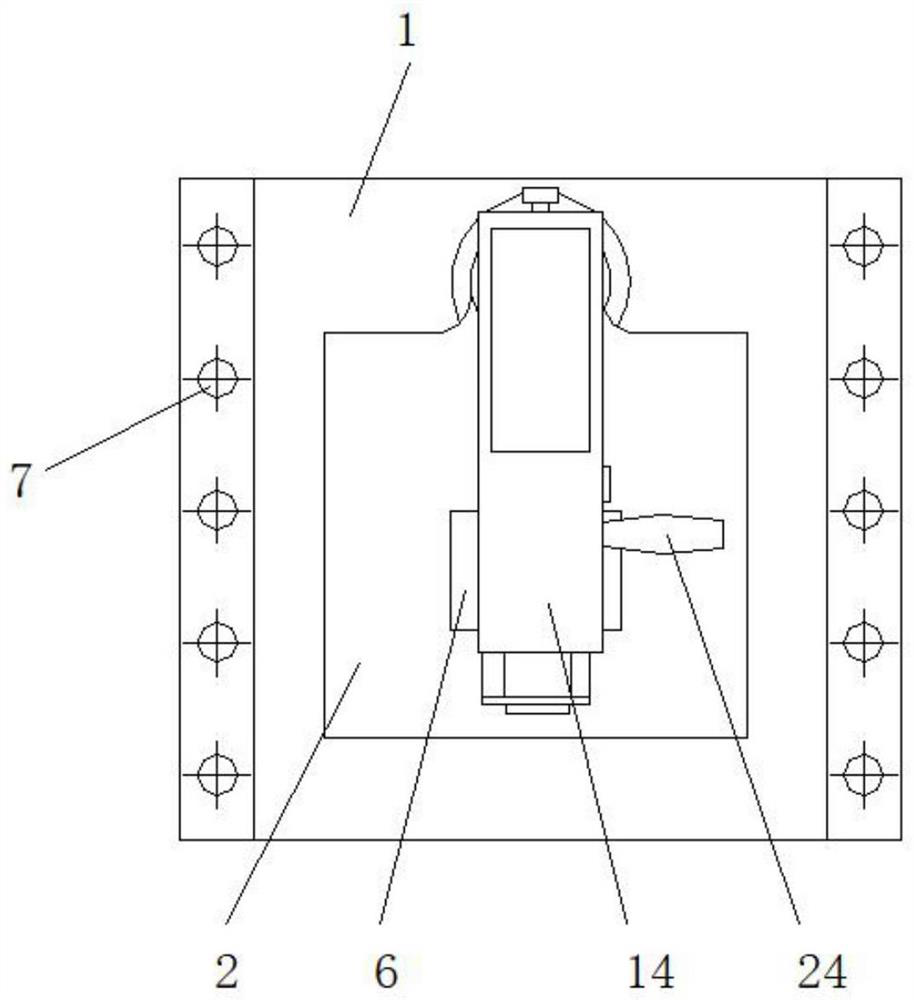

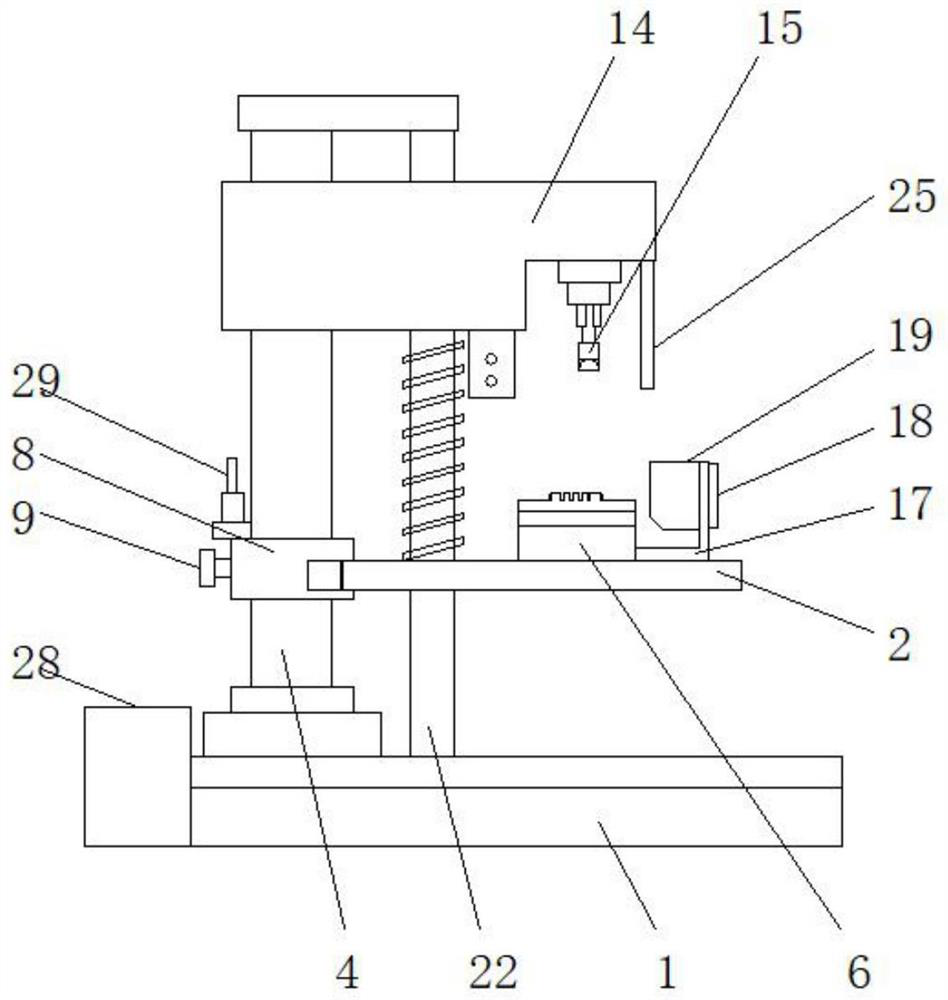

[0025] Example 1, see Figure 1-7 , the present invention provides a technical solution: a rapid cooling manganin shunt welding device, including a base 1, a welding table 2, a cooling mechanism 3, a vertical arm 4, a welding mechanism 5 and a fixing clamp seat 6, the base 1 The edges of the left and right sides are provided with evenly distributed installation holes 7, and the rear edge of the base 1 is fixedly connected with a vertical arm 4, and the vertical arm 4 is vertically distributed with the base 1, and the vertical arm 4 is vertically distributed. The surface is provided with a welding mechanism 5 for sliding connection, and the side wall of the vertical arm 4 is provided with a welding platform 2 that is detachably connected. The edge of the welding platform 2 is fixedly connected with a sliding sleeve 8, and the sliding sleeve 8 is connected to the vertical The arm 4 is slidingly connected and the side wall is provided with a locking bolt 9 that is threaded. The w...

Embodiment 2

[0026] Example 2, see Figure 5 , the technical solution of the present embodiment is the fixing clip seat installed on the welding table. In order to facilitate the fixing and positioning of the manganin shunt, the fixing clip seat on the welding table, the surface of the fixing clip seat 6 is provided with positioning Slot 10, the surface of the positioning groove 10 is provided with a positioning column 11, the left side of the positioning groove 10 is provided with a clamping block 12, the surface of the clamping block 12 is provided with a clamping groove 13, through the fixed clip The surface of the seat 6 is provided with a positioning groove 10 with a positioning column 11, which is convenient for limiting and fixing the manganin shunt. The cables with welding are fixed, which is convenient for welding multiple cables at the same time, and improves the work efficiency of manganese-copper shunt welding.

Embodiment 3

[0027] Example 3, see Figure 1-4 , the technical solution of the present embodiment is a welding mechanism installed on the vertical arm. In order to facilitate the welding operation of the manganin shunt, the welding mechanism is fixed on the vertical arm. The welding mechanism 5 includes a slider 14, a welding head 15 and The wire feeding roller 16, the slider 14 is sleeved on the surface of the vertical arm 4 and is slidably connected with the vertical arm 4, the end of the slider 14 is fixedly connected with a welding head 15, and the bottom of the slider 14 There is a wire feeding roller 16 connected by rotation, and a sliding block 14 is provided on the surface of the vertical arm 4 to facilitate the lifting movement of the sliding block 14. Cooperating with the welding head 15 fixedly connected at the end, it is convenient for manganese copper The shunt is welded, and the bottom of the slider 14 is provided with a wire feeding roller 16, which facilitates automatic del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com