Method for preparing collagen with triple-helix structure through spray drying

A collagen and spray dryer technology, applied in the field of protein preparation, can solve problems such as restricting the use in the field of bio-3D printing, and achieve the effects of good resolubility, reduced energy consumption, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

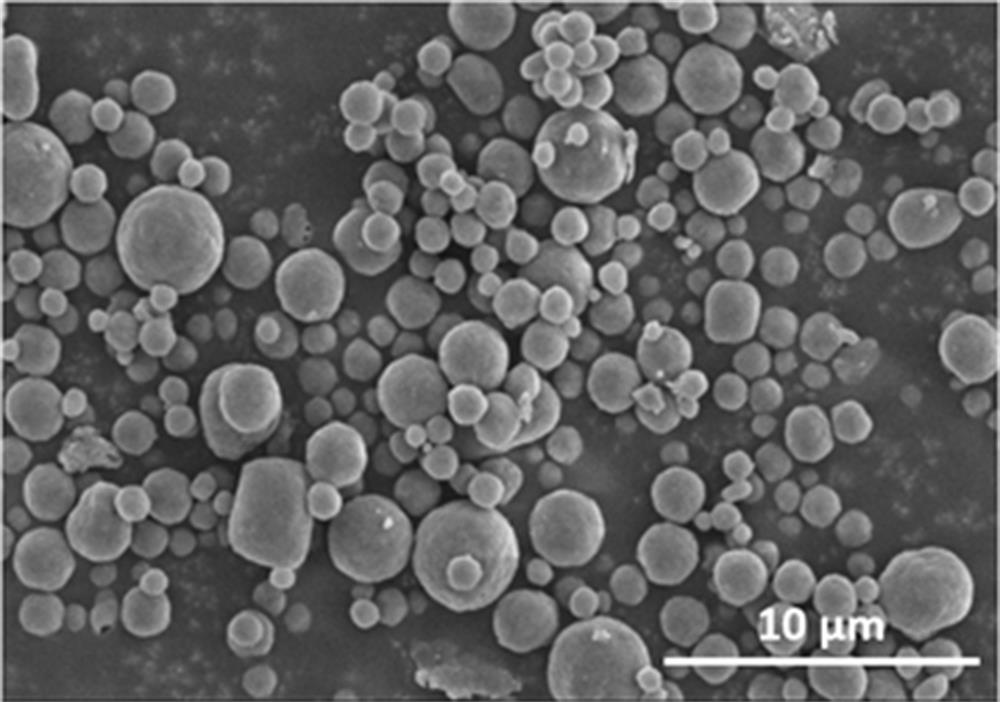

Embodiment 1

[0060] The collagen stock solution used is prepared from pig Achilles tendon with a purity of 99.8%, a concentration of 8 mg / mL, and an rpn value of triple helix structure integrity of 0.12;

[0061] Spray drying: the inlet air temperature is 60±1°C, the feed speed is 30rpm, the outlet air temperature is 50-58°C, and the obtained powder is collected.

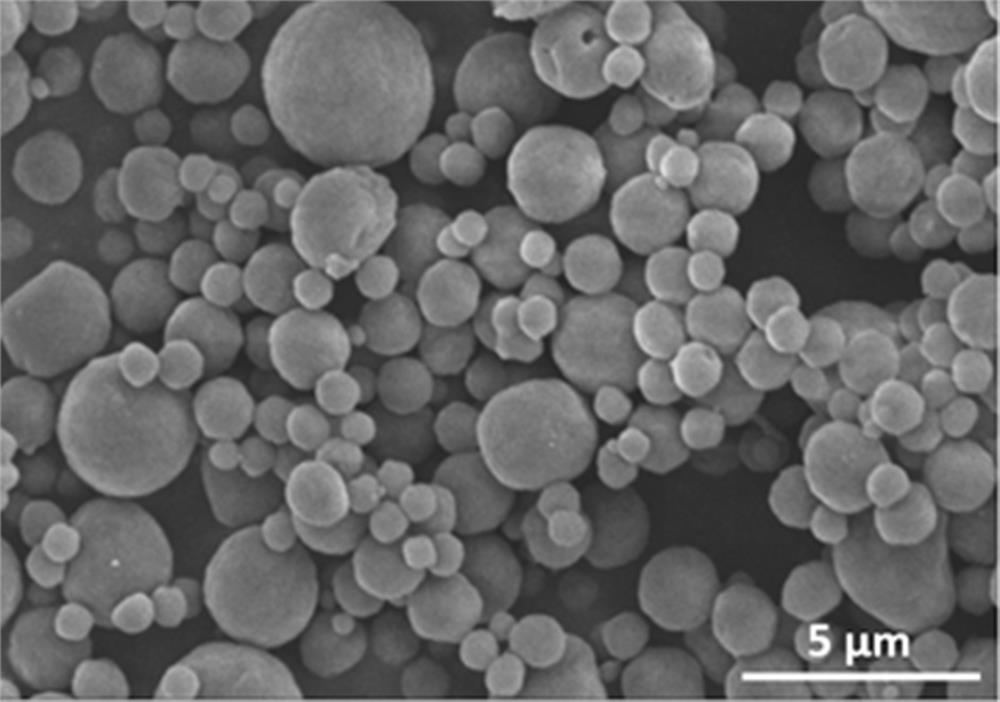

Embodiment 2

[0069] The collagen stock solution used is prepared from bovine Achilles tendon with a purity of 99.8%, a concentration of 15 mg / mL, and an rpn value of triple helix structure integrity of 0.12;

[0070] Spray drying: inlet air temperature: the inlet air temperature is 50±1°C, the feed speed is 25 rpm, the outlet air temperature is 30-40°C, and the obtained powder is collected.

Embodiment 3

[0078] The collagen stock solution used was prepared from rat tail with a purity of 99.8%, a concentration of 20 mg / mL, and an rpn value of triple helix structure integrity of 0.12;

[0079] Spray drying: the inlet air temperature is 40±1°C, the feed speed is 18 rpm, the outlet air temperature is 20°C-30°C, the obtained powder is collected, and sterilized by irradiation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak temperature | aaaaa | aaaaa |

| Heat denaturation temperature | aaaaa | aaaaa |

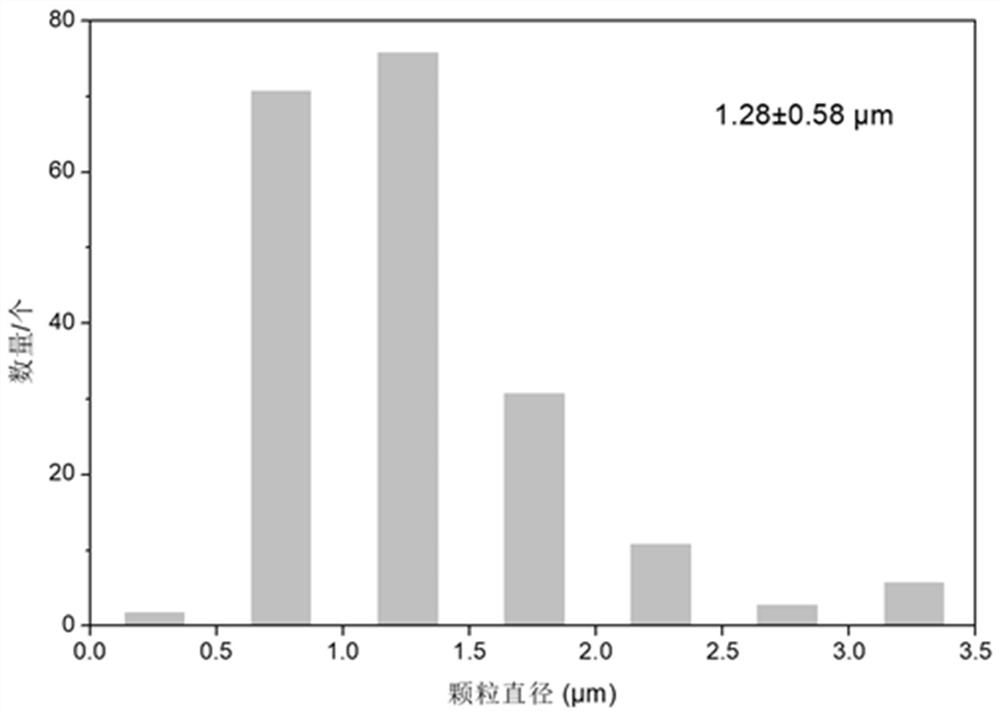

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com