Refrigerating machine oil composition, refrigerant and refrigerating machine oil composition and air conditioning system

A technology of refrigerating machine oil and composition, applied in the fields of refrigerant and refrigerating machine oil composition, air-conditioning system, refrigerating machine oil composition field, can solve problems such as poor lubricity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

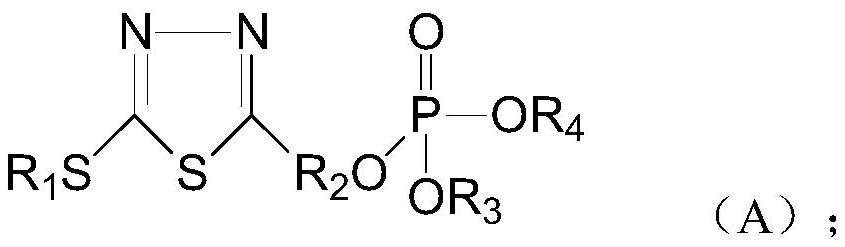

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Hereinafter, the present invention will be more specifically described based on examples and comparative examples, but the present invention is not limited at all by the following examples.

[0088] Base Oil: Polyol Esters.

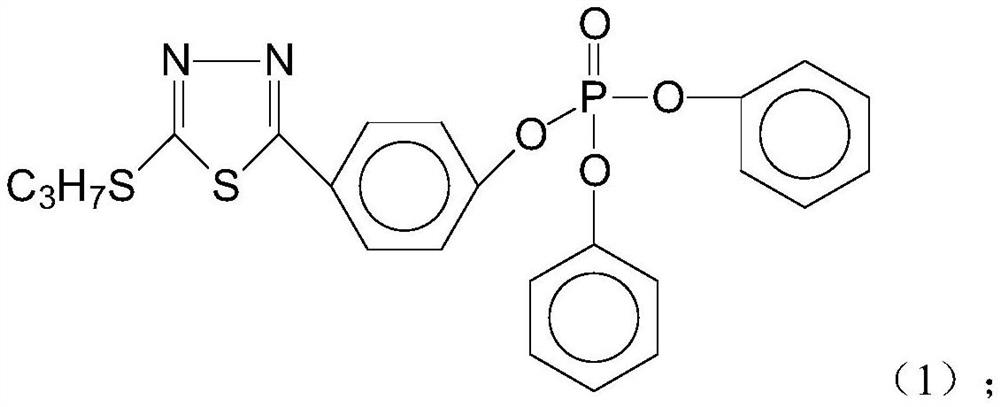

[0089] Additive 1: compound represented by formula (1)

[0090]

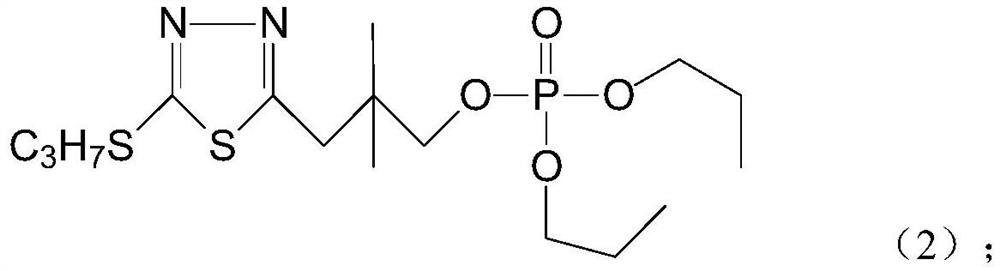

[0091] Additive 2: compound shown in formula (2)

[0092]

[0093] Additive 3: compound shown in formula (3)

[0094]

[0095] Additive 4: 2,6-di-tert-butyl-p-cresol

[0096] Additive 5: Octyl glycidyl ether

[0097] Additive 6: Simethicone oil

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com