Water-lubricated overload protection lubricating oil line supply system and water-lubricated overload protection method

An overload protection and water lubrication technology, which is applied in lubricating parts, engine lubrication, hydropower generation, etc., can solve problems such as lubrication failure, wear failure, and low water film bearing capacity, and achieve the effect of increased thickness and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

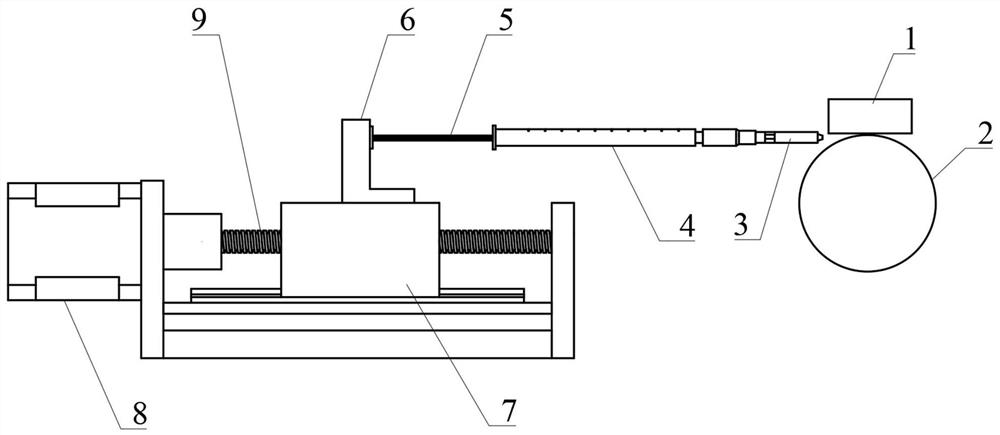

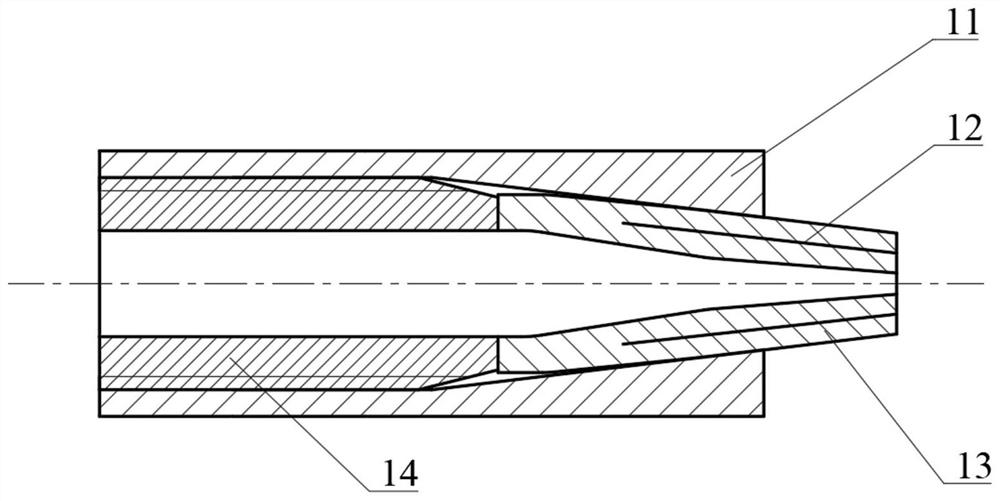

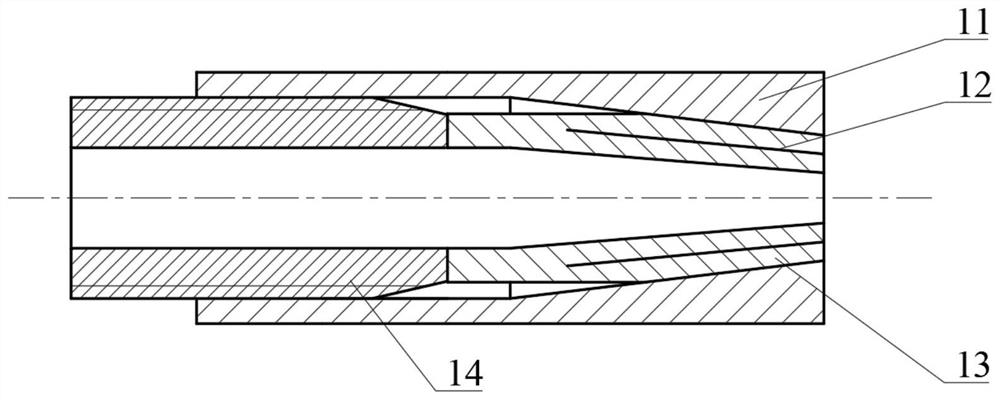

[0036] This embodiment relates to a water-lubricated overload protection method. When the water-lubricated friction pair is overloaded, lubricating oil enters the water-lubricated friction pair in the form of an oil thread in the water for auxiliary lubrication of the lubricating oil, so as to protect the water-lubricated friction pair. The purpose of the friction pair material, taking the ring block testing machine as an example, the specific steps are as follows:

[0037] S1. According to the load W between the materials of the water-lubricated friction pair and the viscosity μ of the lubricating medium, use a ring block testing machine to measure the curve of the friction coefficient changing with the speed of the steel ring. The specific measurement method is: use the common water-lubricating material nitrile rubber As the grinding block 1, the surface roughness is 0.4; 316 stainless steel is used as the grinding ring 2, and the surface roughness is 0.3; tap water is used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com