A high temperature resistant high density synthetic base drilling fluid

A synthetic base and drilling fluid technology, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of high drilling fluid circulation density, unfavorable suspension of drilling cuttings, high formation pressure coefficient, etc., and achieve the reduction of differential pressure stuck Drilling risk, good reservoir protection effect, good filtration and wall building effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

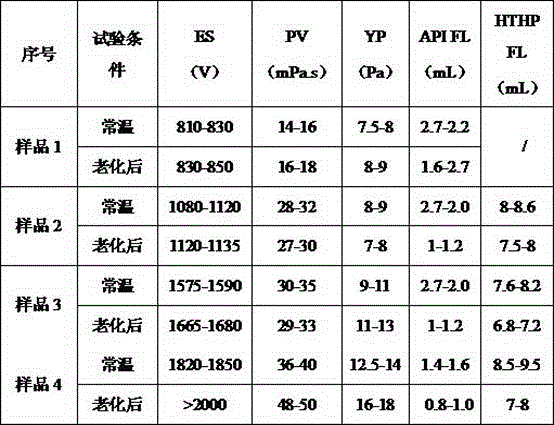

Examples

Embodiment 1

[0035] Use quaternary ammonium salt products and fatty amide polyvinyl ether products to configure a density of 0.85 g / cm 3 Put 60 liters of synthetic-based drilling fluid in a stirring container, put the stirring container in a 50°C water bath, then add 4 liters of polyoxyethylene ether product mixture, quaternary ammonium salt products and fatty acid amide into the stirring container in sequence 1 liter of auxiliary emulsifier formed by mixing polyvinyl ether products, 4.5 liters of organic soil obtained by modifying long carbon chain alkyl quaternary ammonium salts by montmorillonite clay minerals, stirred for 10 minutes to fully dissolve; Then add 1.5 liters of the mixture of glycerol products in turn, stir for 2 minutes, add 5 liters of wetting modifiers mixed with organic acid amide products and hydantoin products, stir for 2 minutes, add styrene-butadiene Mix 0.5 liters of synthetic product of rubber and polystyrene, stir for 10 minutes to fully dissolve; add 4 liters o...

Embodiment 2

[0037] Use quaternary ammonium salt products and fatty amide polyvinyl ether products to configure a density of 1.2 g / cm 3 Put 90 liters of synthetic-based drilling fluid in a stirring container, put the stirring container in a 50°C water bath, and then add 2 liters of a mixture of polyoxyethylene ether products, quaternary ammonium salt products and fatty amide to the stirring container in sequence 3 liters of co-emulsifiers mixed with polyvinyl ether products, 2 liters of organic soil obtained by modifying long carbon chain alkyl quaternary ammonium salts by montmorillonite clay minerals, stirred for 10 minutes to fully dissolve; Then add 3 liters of the mixture of glycerol products in turn, stir for 2 minutes, add 1 liter of wetting regulator mixed with organic acid amide products and hydantoin products, stir for 2 minutes, add butylbenzene Add 1.5 liters of rubber and polystyrene synthetic product, stir for 10 minutes to fully dissolve; add 1.5 liters of modified asphalt, ...

Embodiment 3

[0039] Use quaternary ammonium salt products and fatty amide polyvinyl ether products to configure a density of 1.2 g / cm 3 Put 70 liters of synthetic base drilling fluid in a stirring container, put the stirring container in a 50°C water bath, and then add 3 liters of a mixture of polyoxyethylene ether products, quaternary ammonium salt products and fatty acid amide into the stirring container in sequence 2 liters of co-emulsifiers mixed with polyvinyl ether products, 3 liters of organic soil obtained by modifying long carbon chain alkyl quaternary ammonium salts by montmorillonite clay minerals, stirred for 10 minutes to fully dissolve; Then add 2 liters of the mixture of glycerol products in turn, stir for 2 minutes, add 3 liters of wetting modifiers mixed with organic acid amide products and hydantoin products, stir for 2 minutes, add styrene-butadiene Mix 1 liter of synthetic product of rubber and polystyrene, stir for 10 minutes to fully dissolve; add 3 liters of modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com