Fluid driving method based on algae cells

A fluid-driven, algae cell technology, applied in biochemical equipment and methods, specific-purpose bioreactors/fermenters, biochemical instruments, etc., to achieve the effect of solving energy supply and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

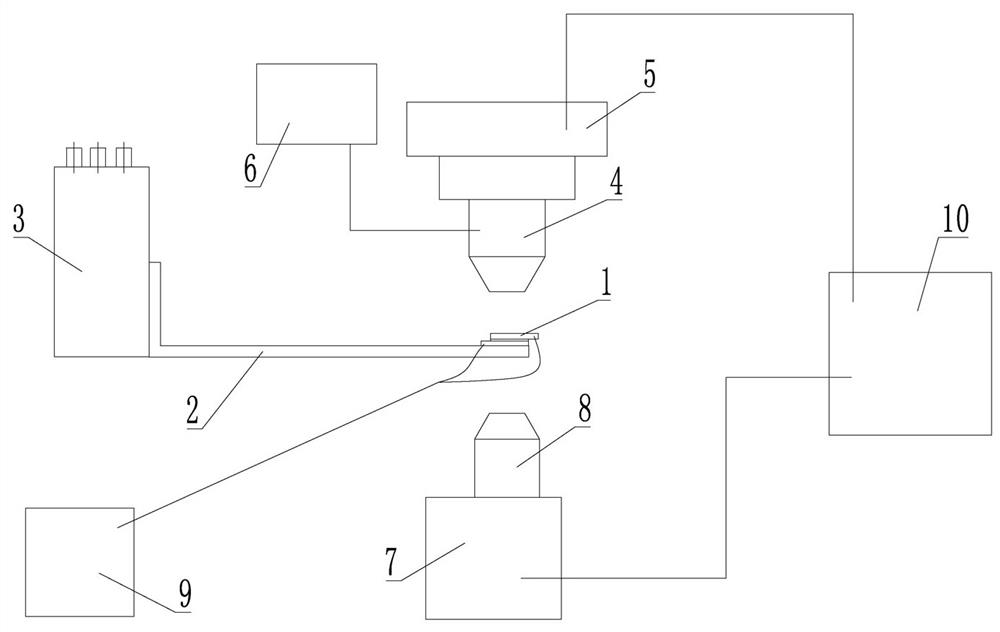

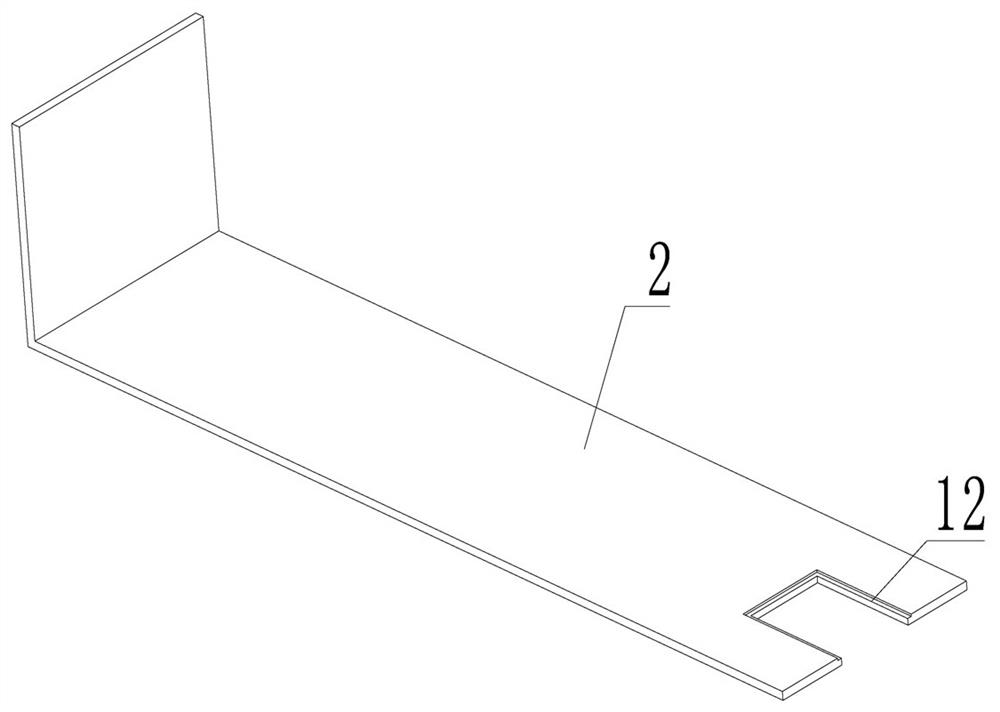

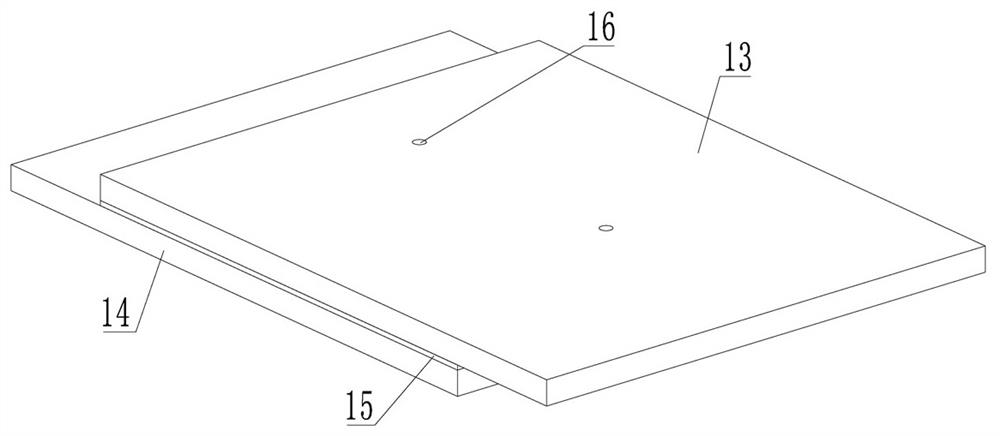

[0036] Such as Figure 1-Figure 6 As shown, based on the fluid drive method of algae cells, (1), design a viscous micropump, which includes a fluid drive chip 1, an L-shaped adapter plate 2, a three-dimensional nano-mobility platform 3, a microscope 4, a CCD5, a high Precision Z-direction translation stage 6, projector 7, focusing objective lens 8, signal generator 9 and computer 10, fluid drive chip 1 is arranged horizontally, and the upper surface of fluid drive chip 1 is provided with fluid inlet and fluid outlet at intervals on the left and right, fluid drive chip 1 A micro-pipe 11 between the fluid inlet and the fluid outlet is provided along the left and right direction, the fluid inlet is connected to the left end of the micro-pipe 11, the fluid outlet is connected to the right end of the micro-pipe 11, and the L-shaped adapter plate 2 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com