Assembly for guiding gas circulation in silicon wafer epitaxial process and epitaxial growth device

An epitaxial process and guide technology, which is applied in the field of semiconductor silicon wafer production, can solve the problems of gas loss on the surface of silicon wafers, the inability to realize the thickness of the epitaxial layer, and insufficient guarantee of installation accuracy, so as to avoid overall uneven distribution and avoid Effect of Local Gas Loss, Flatness and Thickness Uniformity Guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

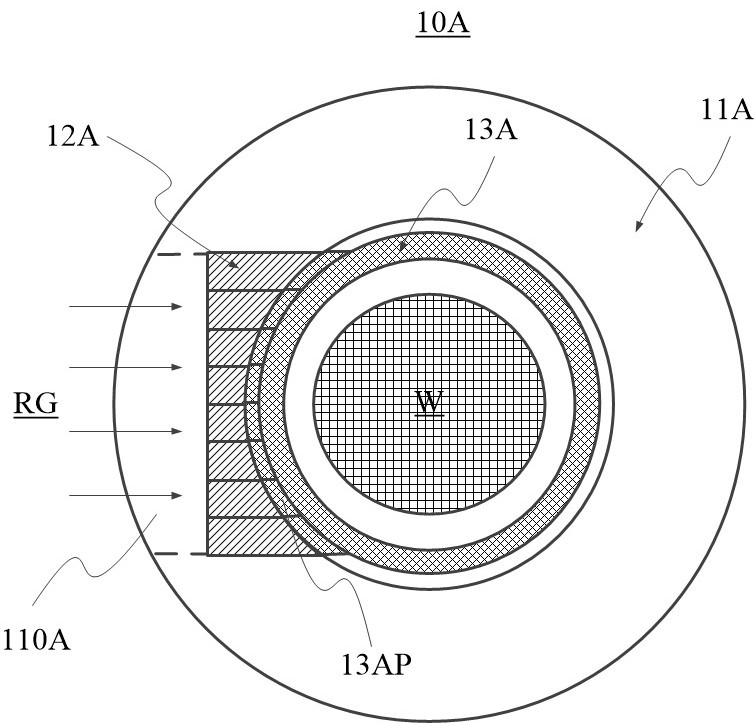

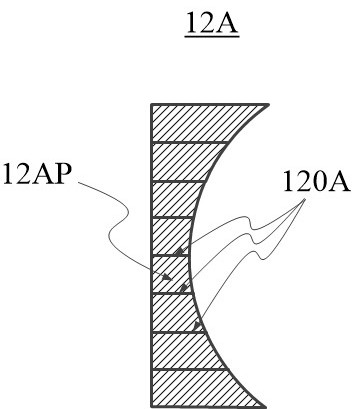

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

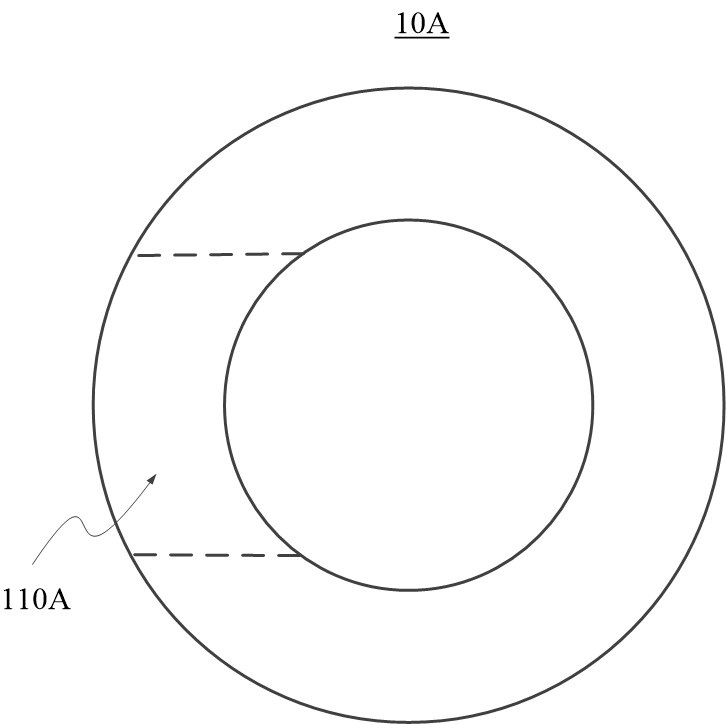

[0043] see Figure 8 , which shows a top view of an assembly 10 for guiding the flow of gas G during the epitaxial process of a silicon wafer W provided by an embodiment of the present invention. Figure 8In , the silicon wafer W is schematically shown by the hatched area filled by the box, and the gas G is schematically shown by the parallel arrow lines. It should also be noted that in this article, there will be no flow to the silicon wafer W or The gas G that has not yet reacted with the silicon wafer W is called the reactive gas RG, and the gas G that has flowed through the silicon wafer W or has reacted with the silicon wafer W is called the reaction tail gas TG. The assembly 10 may include:

[0044] Surrounding the base ring 11 of the silicon wafer W, the base ring 11 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com