Beta-gallium oxide crystal and growth method and application thereof

A growth method, gallium oxide technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of polycrystalline β-gallium oxide crystals, reduce the growth quality of β-gallium oxide crystals, and improve the growth quality , less oxygen vacancy defects, and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

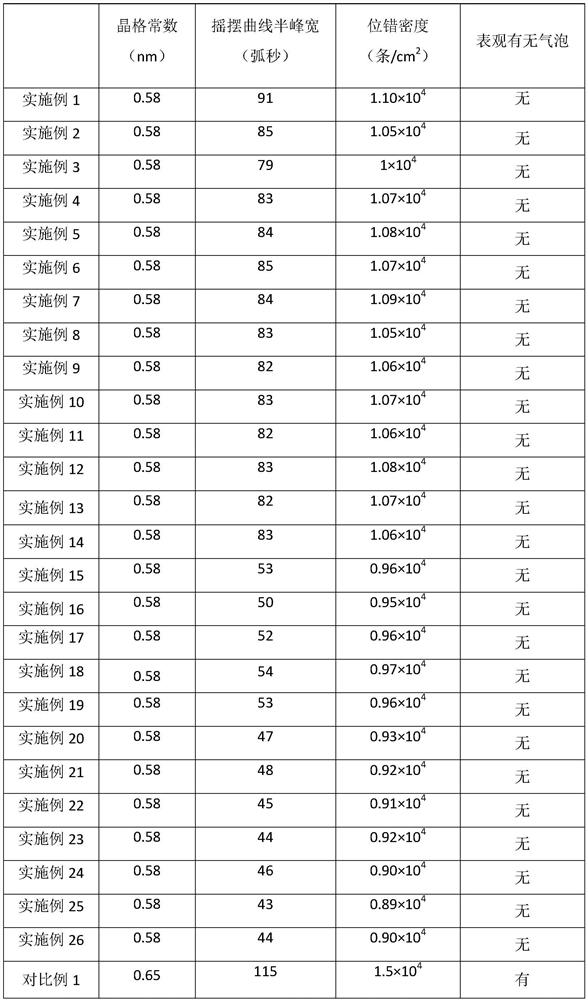

Examples

Embodiment 1

[0039] The β-gallium oxide crystal of Example 1 was prepared by the following method:

[0040] (1) Add the gallium oxide raw material into the mold in the crucible, insert one end of the seed rod into the growth furnace, and connect the other end with a lifting device, place the seed crystal at the lower end of the seed rod and directly above the mold, so that When the seed rod is pulled, the seed crystal touches the liquid surface at the top of the mold;

[0041] Under the condition of 0.5MPa pure argon, the temperature in the furnace is heated to 1840°C to melt the gallium oxide raw material in the crucible;

[0042] (2) Lower the seed rod to weld the seed crystal to the gallium oxide raw material on the top of the mold; pull the seed crystal at a rate of 6 mm / h to start seeding;

[0043] (3) When the seeding length reaches 10 mm, continue to pull the seed rod at a rate of 6 mm / h, and at the same time lift the crucible at 0.4 mm / h to make the crystal shoulder spontaneously;...

Embodiment 2

[0045] The β-gallium oxide crystal of Example 2 was prepared by the following method:

[0046] (1) Under the condition of 99% argon and 1% oxygen at 0.5MPa, the temperature in the furnace is heated to 1840°C to melt the gallium oxide raw material in the crucible;

[0047] (2) with embodiment 1;

[0048] (3) with embodiment 1.

Embodiment 3

[0050] The β-gallium oxide crystal of Example 3 was prepared by the following method:

[0051] (1) Under the conditions of 95% argon and 5% oxygen at 0.5MPa, the temperature in the furnace is heated to 1840°C to melt the gallium oxide raw material in the crucible;

[0052] (2) with embodiment 1;

[0053] (3) with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com