Hydraulic clearance self-adjusting special driving cam combined type valve driving device

A technology for driving cams and driving devices, which is applied in the direction of valve driving devices, valve devices, engine components, etc., and can solve the problems of incompatibility of combined engine valve driving devices and the inability to automatically adjust valve clearances, etc., to solve the problem of functional compatibility and use Easy maintenance, improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

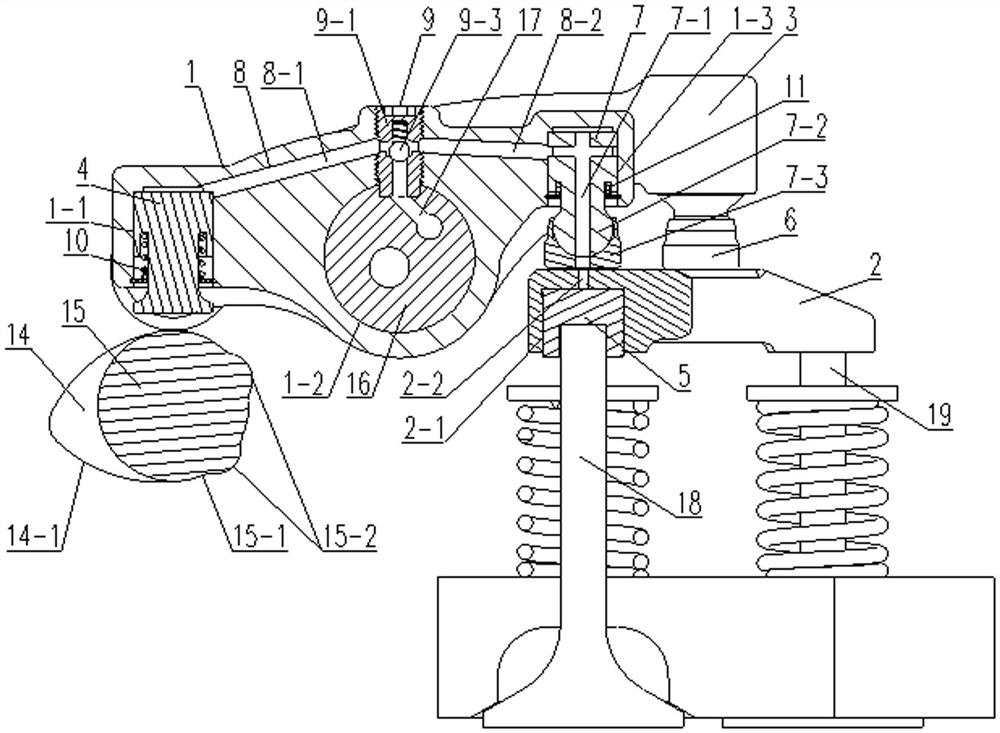

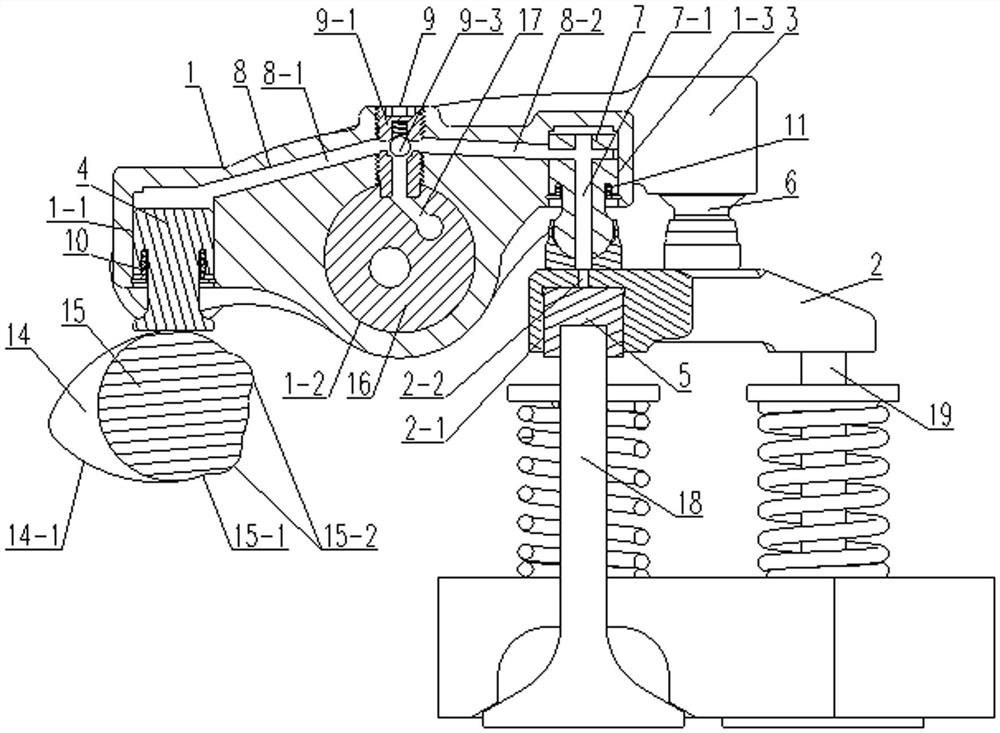

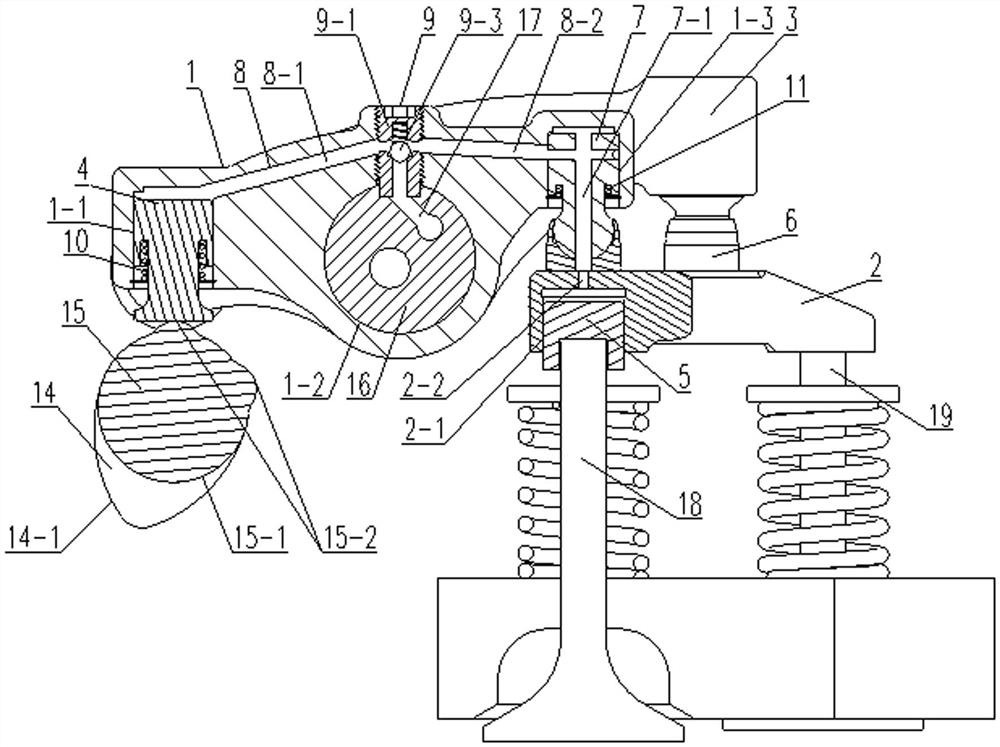

[0048] Such as Figure 1-8As shown, a hydraulic clearance self-adjusting special driving cam combined valve driving device, the engine is a four-stroke engine, the driving valve 18 and the non-driving valve 19 of the valve group are exhaust valves in the engine, and the valve driving device includes:

[0049] The driver 1 has a main piston 4 slidably installed in the main piston hole 1-1, an actuating piston 7 slidably installed in the actuating piston hole 1-3, and a piston connected between the main piston hole 1-1 and the actuating piston hole 1-3. The driving oil passage 8 between the actuator piston 7 runs through the inner oil passage 7-1 communicating with the actuator piston hole 1-3, and the driver 1 is fixedly installed on the rocker shaft 16;

[0050] The rocker arm 3 is equipped with a hydraulic gap adjuster 6, and the rocker arm 3 is rotated and installed on the rocker arm shaft 16;

[0051] The special-purpose drive cam 15 is located on one side of the positive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com