Denitration combustion device of biomass boiler

A biomass boiler and combustion device technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve problems such as corrosion of the inner wall of the pipeline, and achieve the effects of avoiding corrosion, increasing service life, and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

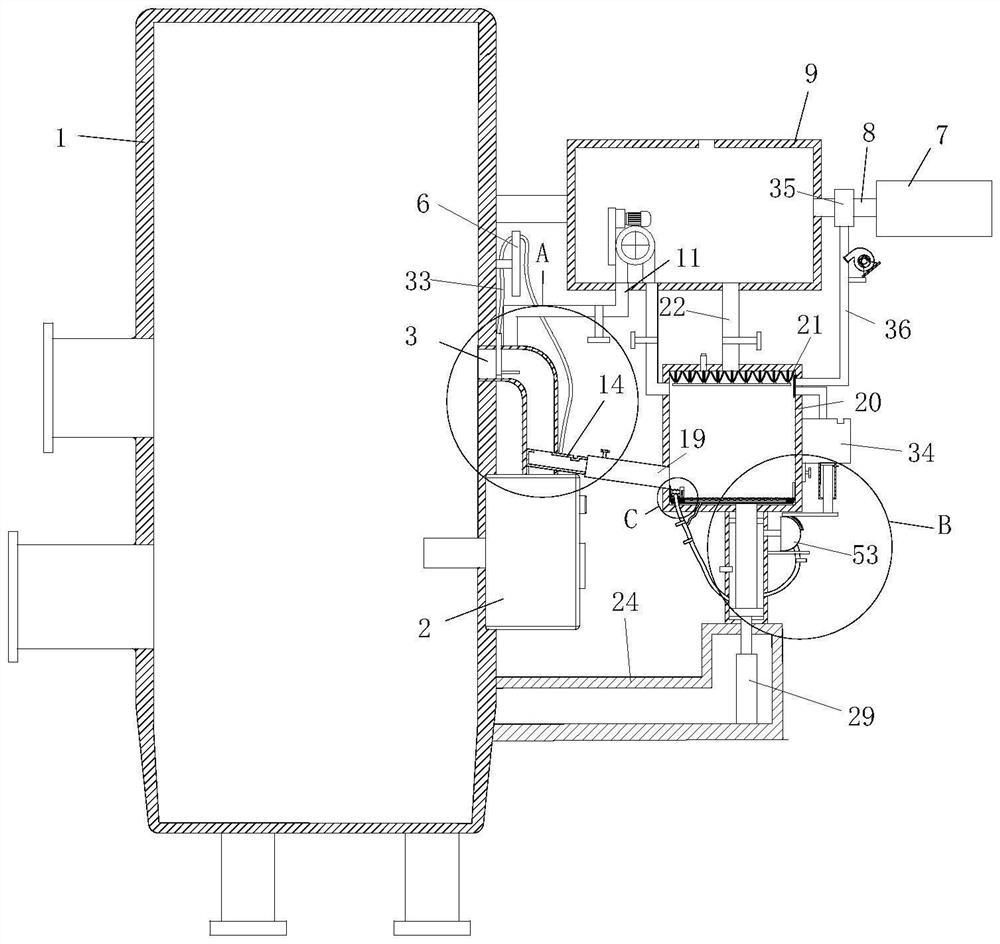

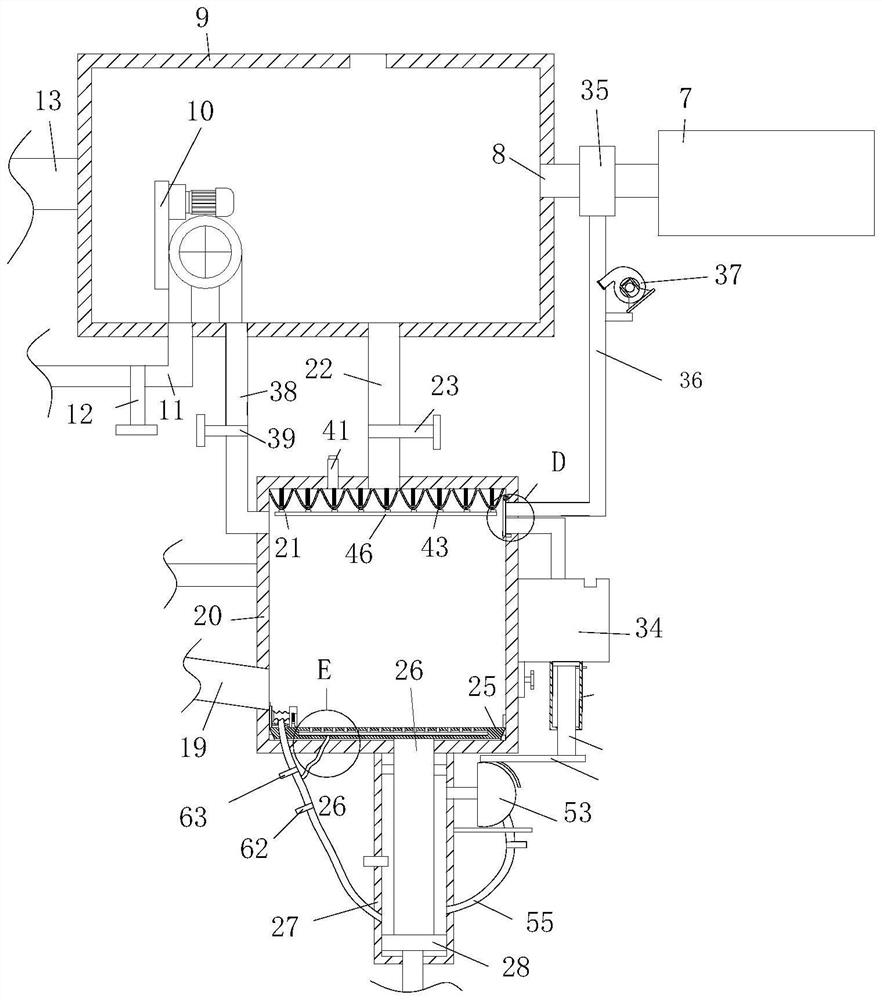

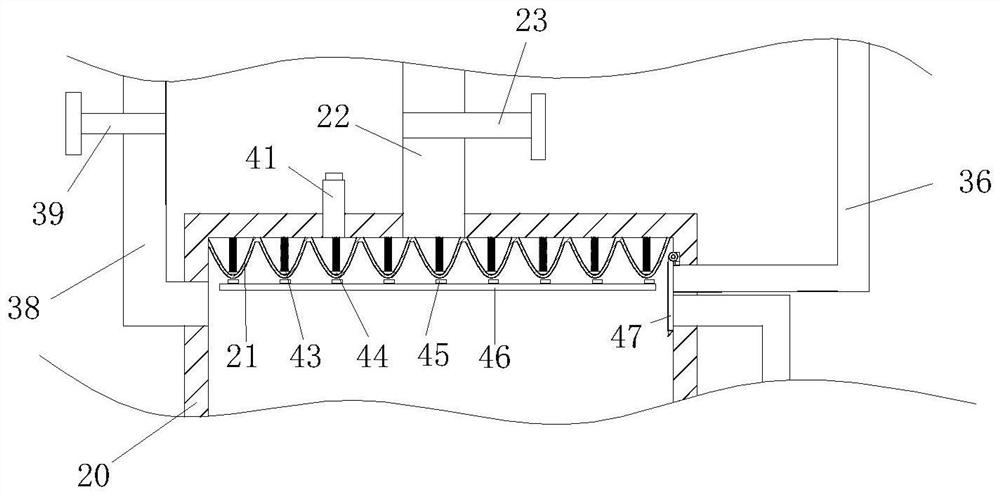

[0034] Such as Figure 1 to Figure 4 As shown, the biomass boiler denitrification combustion device described in the embodiment of the present invention includes a furnace body 1; A pipeline 3 is communicated between them. A water tank 9 is provided on one side of the furnace body 1. The water tank 9 is fixedly connected with the furnace body 1 by means of a bracket. A water inlet is provided at the top of the water tank 9. There is a heating pipe 8, the other end of the heating pipe 8 is fixedly installed with a natural gas heater 4, the bottom end of the water tank 9 is communicated with a water inlet pipe 11, and a first valve 12 is installed on the water inlet pipe 11, and the inlet The end of the water pipe 11 far away from the water tank 9 communicates with the pipeline 3, and the water retaining plate 15 is slidably connected to the pipe 3, and the surface of the water retaining plate 15 is sealed and connected to the pipe 3, and the water outlet pipe 14 is slidably con...

Embodiment 2

[0043] Such as Figure 3 to Figure 10 Shown, comparative example one, wherein another kind of implementation mode of the present invention is:

[0044] A third air valve 63 is installed on the second air pipe 56, an elastic rope 69 is fixedly installed between the sliding block 60 and the support plate 58, a rectangular groove is opened inside the bottom plate 25, and a pusher is sealed in the rectangular groove. plate 66, the top of the pushing plate 66 is evenly fixed with a sliding post 65, the sliding post 65 is connected to the inside of the bottom plate 25 by sliding, the bottom end of the scraper 61 is arc-shaped, and one of the scraper 61 The connection drive plate 68 on the side, the second spring 67 is fixedly connected between the drive plate 68 and the sliding block 60, the bronchus 64 is communicated with the second air pipe 56, and the bronchus 64 communicates with the rectangular groove, by opening the third Air valve 63, and close the air valve, use the air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com