Low-temperature mounting structure for grating assembly of long-wave infrared Doppler differential interferometer

A differential interference, long-wave infrared technology, used in instruments, measuring devices, speed/acceleration/shock meter details, etc., can solve problems such as thermal expansion coefficient mismatch, grating element position change, interference fringe inclination, etc., to achieve position offset Small, easy to install and adjust, reduce the effect of thermal expansion coefficient mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

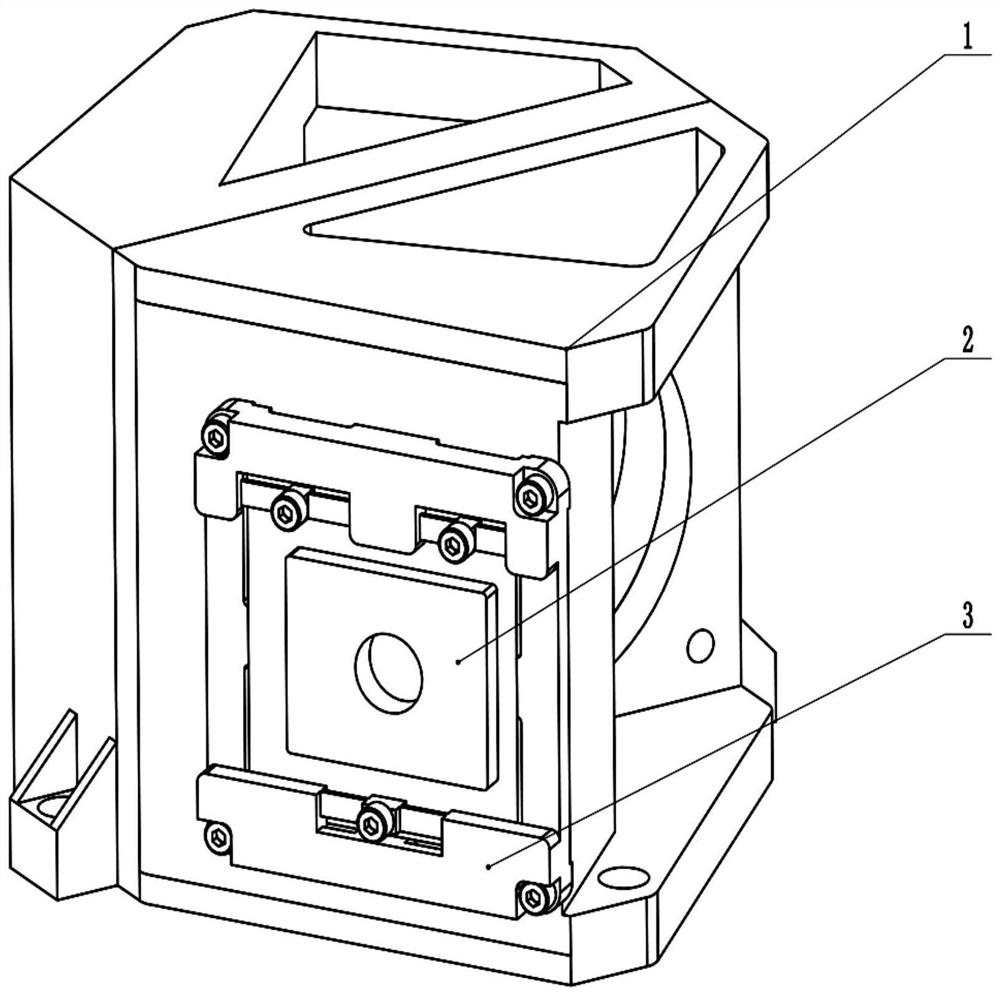

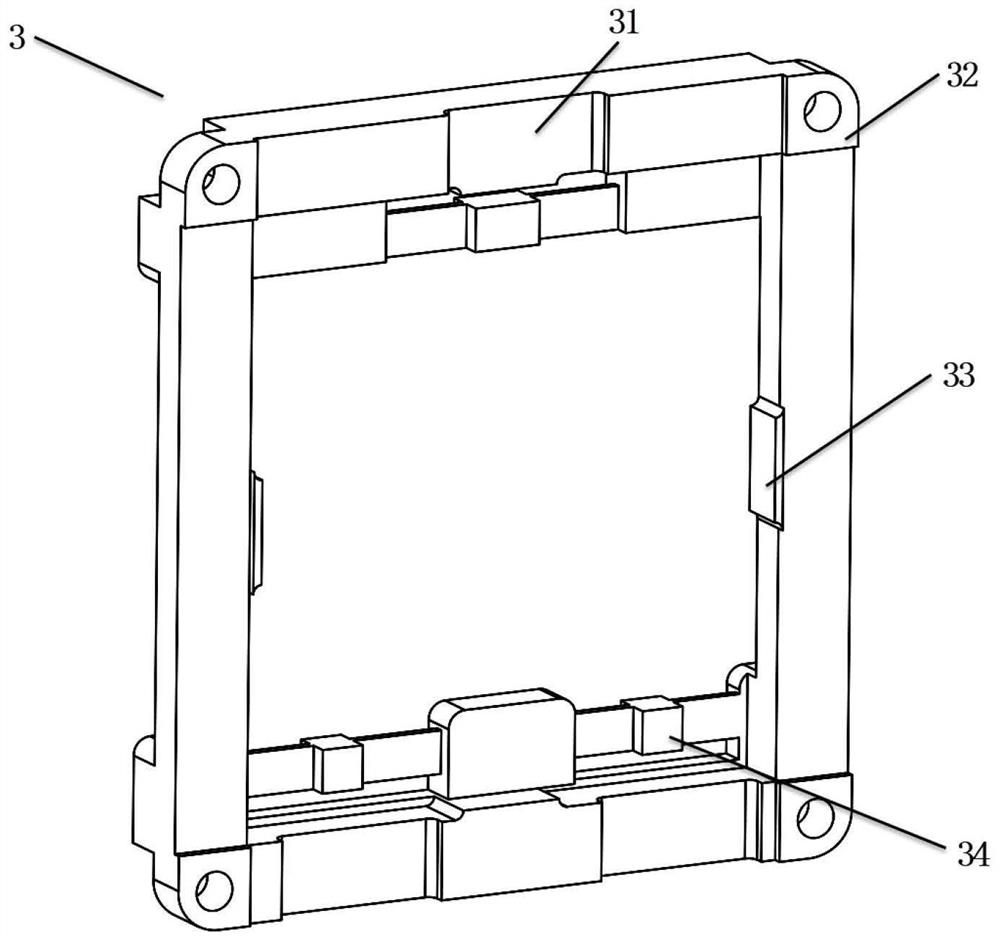

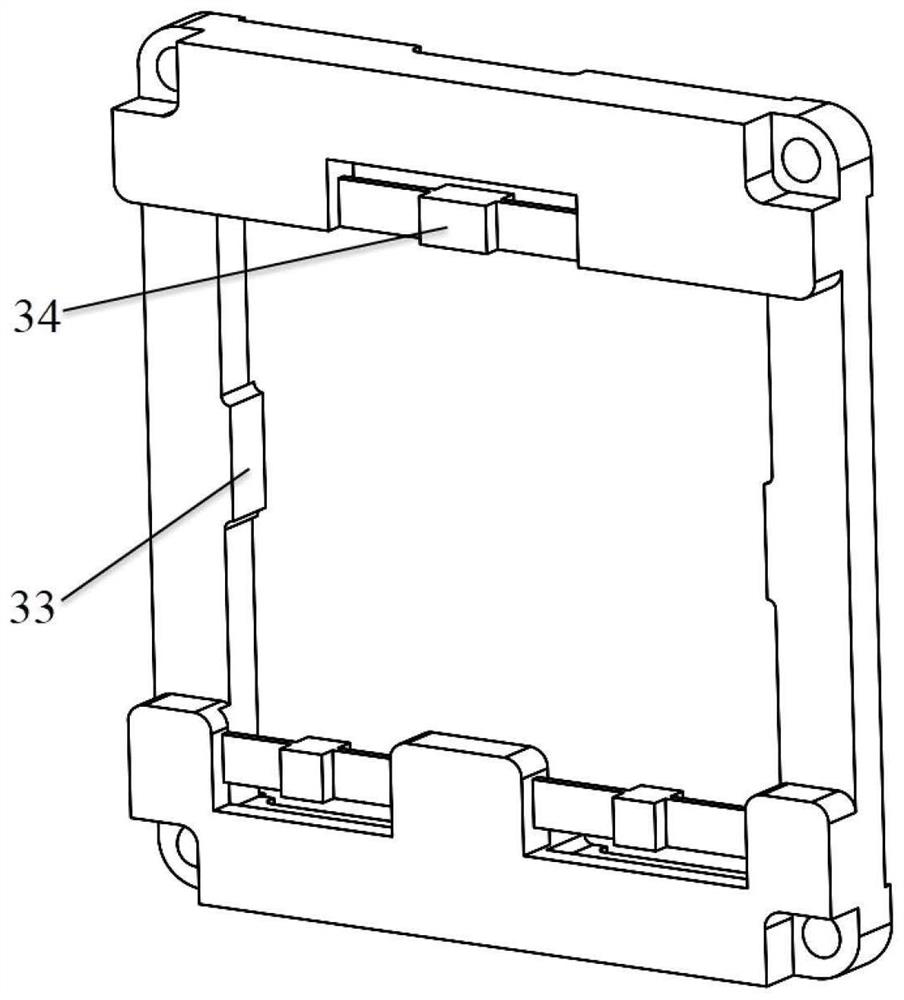

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the low-temperature installation structure of a long-wave infrared Doppler differential interferometer grating assembly provided by the present invention includes an interferometer bracket 1 , a grating pressing plate 2 , and a grating pressing plate fixing member 3 . The grating pressing plate 2 and the grating pressing plate fixing part 3 are made of aluminum alloy. Such as Figure 4 As shown, the grating pressing plate 2 is installed with grating components inside, and the front surface of the grating pressing plate 2 is provided with three boss mounting surfaces 21, and the boss mounting surfaces 21 are all located on the surface edge of the grating pressing plate 2; when the grating pressing plate 2 is installed on the interferometer support 1, the convex The table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

| Parallelism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com