A kind of low contact resistance resistance paste

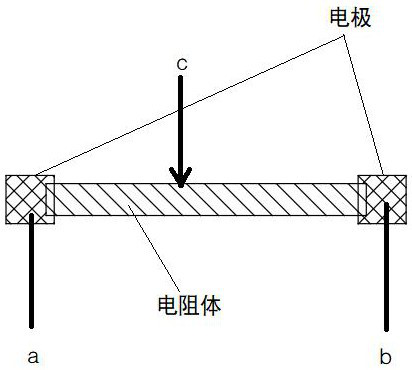

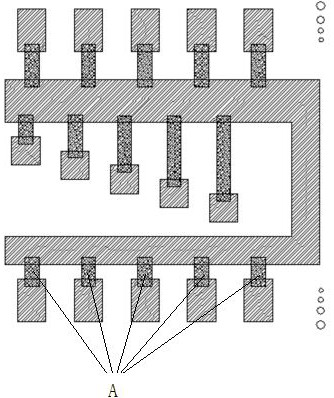

A technology of low contact resistance and resistance paste, which is applied in the direction of sliding contact resistors, resistors, adjustable resistors, etc., can solve the problems of contact point heating and sparking, resistor failure, etc., to achieve smooth surface and small contact resistance , The effect of strong process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] 1. Preparation of conductive powder

[0023] Preparation of conductive phase 1:

[0024] Step 1: Ruthenium nitrate is dissolved in pure water to form Ru 3+ Solution A with an ion concentration of 1mol / L was dissolved in pure water to form Pb 2+ Solution B with an ion concentration of 1mol / L was added to pure water to form a suspension C with a graphyne concentration of 5g / L.

[0025] Step 2: Follow Ru 3+ with Pb 2+ The molar ratio is 1:1, the 500mL solution A and 500mL solution B are added dropwise to 1000mL suspension C under stirring conditions, and after the solution A and B are added dropwise, stop stirring and stand for 24 hours.

[0026] Step 3: After standing the solution, the liquid in the upper layer of the precipitate is extracted, and pure water is re-added to the extracted liquid and stirred for 10 minutes, and then left to stand for 24 hours.

[0027] Step 4: Repeat step 3 twice, then filter and freeze-dry the underlying sediment.

[0028] Step 5: Calcinate the...

Embodiment 2

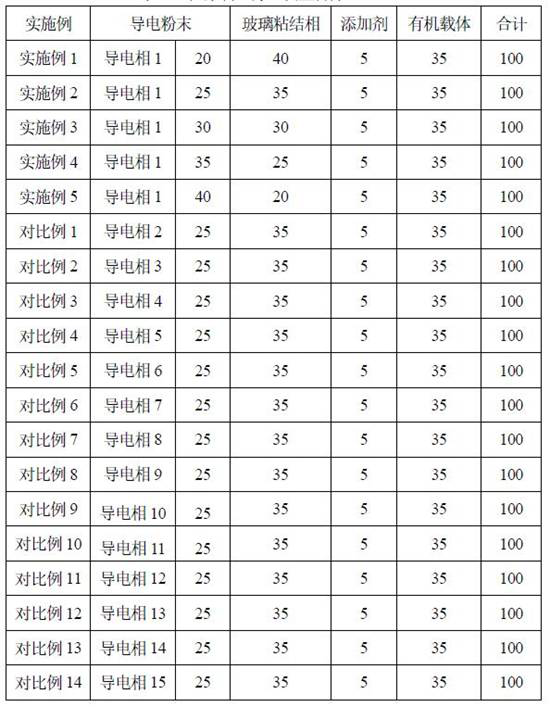

[0059] Example 2 and the use of graphite composite lead ruthate and carbon black composite lead ruthate as a conductive phase in the proportion of 1, 2, indicating that the use of graphite alkyne composite lead ruthate as a conductive phase, in order to obtain excellent temperature coefficient, electrostatic discharge, encapsulation rate of change, contact resistance is small.

[0060] Example 2 is compared with the proportions 3, 4, 5, 6, illustrating that when preparing graphyne composite lead ruthate by chemical deposition method, it is necessary to freeze dry, vacuum calcination process, which is applied to the resistance slurry to obtain the characteristics of excellent temperature coefficient and small contact resistance.

[0061] Example 2 is compared with a counter-proportional ratio of 7 to 14, indicating that whether it is directly using ruthenium dioxide and lead oxide and graphite alkyne, carbon black or graphite composite, or directly using lead ruthate and graphite a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com