Photovoltaic cell, manufacturing method thereof and photovoltaic module

A photovoltaic cell and manufacturing method technology, applied in the field of solar energy, can solve the problems of large internal stress, reduce the light absorption rate of photovoltaic cells, reduce the absorption rate of a silicon nitride film layer, etc., so as to improve the absorption rate and reduce incident to photovoltaic modules. The effect of the loss of light on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It can be seen from the background art that the light absorption rate of photovoltaic cells needs to be improved.

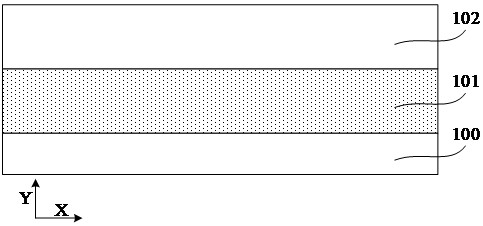

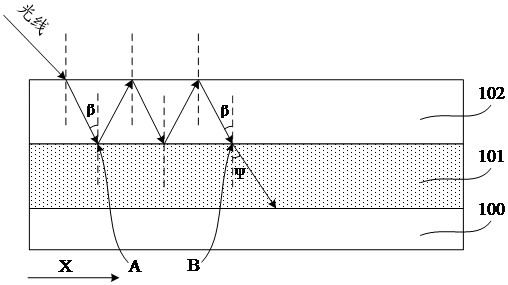

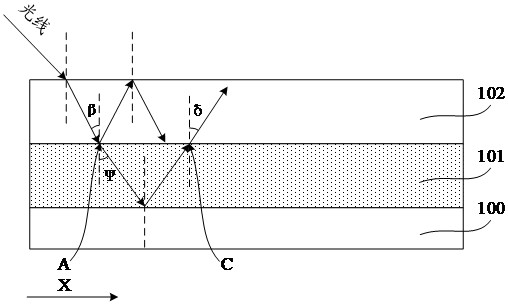

[0030] The implementation of the present application provides a photovoltaic cell, along the direction perpendicular to the direction of the first anti-reflection layer pointing to the direction of the second anti-reflection layer, the content of oxygen element and nitrogen element in one of the first anti-reflection layer and the second anti-reflection layer The ratio shows an increasing trend, and the content ratio of the oxygen and nitrogen elements of the other shows a decreasing trend. In this way, along the direction perpendicular to the direction of the first anti-reflection layer pointing to the direction of the second anti-reflection layer, it is beneficial to make the first anti-reflection layer Both the reflective layer and the second anti-reflection layer have a gradual change in the refractive index of light, and the change trends of the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com