CO2 adsorbent based on multi-source solid waste modification and preparation method and application thereof

An adsorbent and modification technology, which is applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of capture cost and cycle adsorption performance, weak cycle adsorption capacity, safety and environmental protection hazards, etc. Achieve harmless treatment, improve adsorption performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

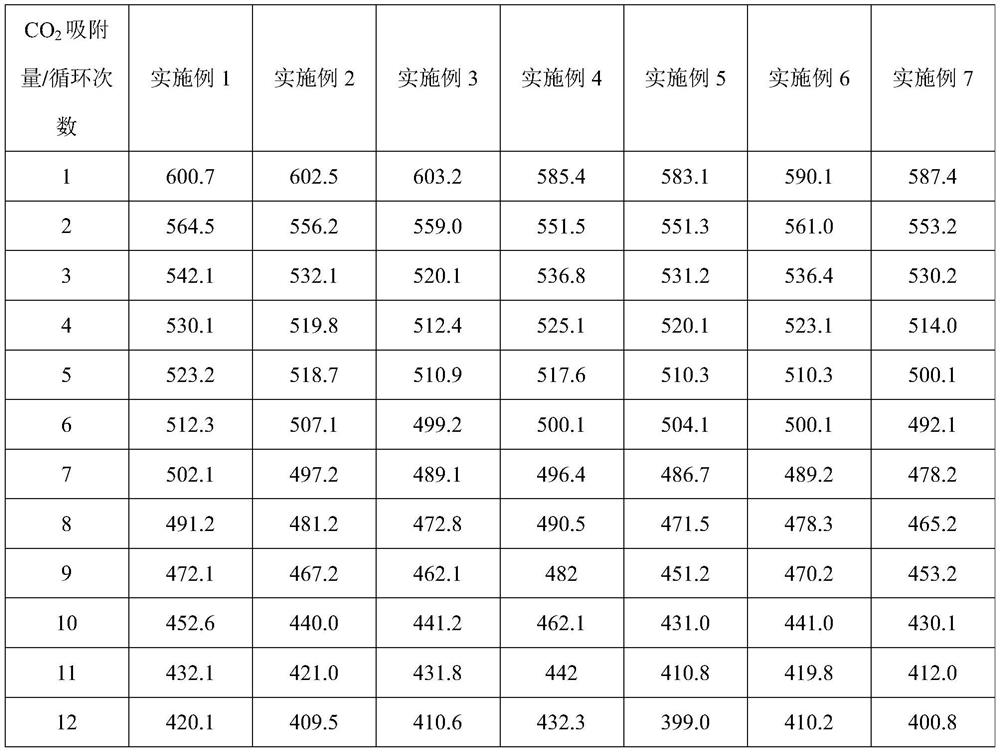

Embodiment 1

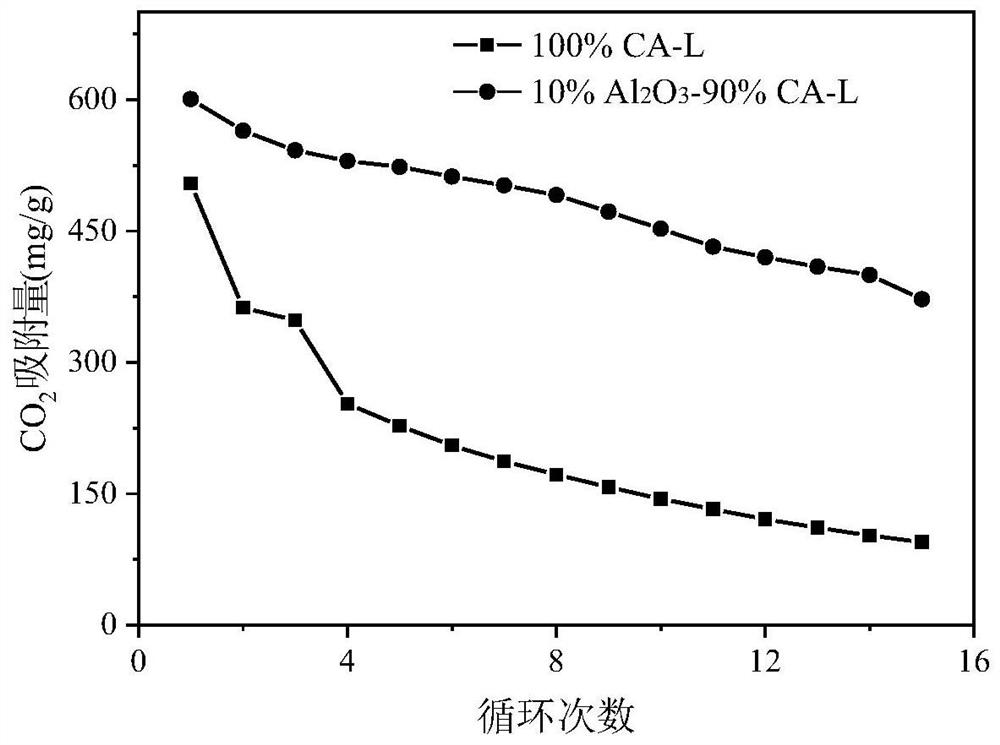

[0049] This example provides a CO based on multi-source solid waste modification 2 The preparation method of adsorbent, described preparation method comprises the following steps:

[0050] (1) Limestone was immersed in 1mol / L NaCl solution for 2 hours, calcined at 1000°C at a heating rate of 5°C / min for 2h, and then ball milled at a speed of 300r / min for 25min to obtain an adsorbent;

[0051] (2) Al 2 o 3 Dry at 130°C for 2 hours, ball mill at 300r / min for 25 minutes, and 1g of Al after ball milling 2 o 3 Mixed with 9g of the adsorbent described in step (1), the obtained mixture was ball milled at 300r / min for 25min, and then calcined at 800°C for 2h at a heating rate of 5°C / min to obtain the CO 2 Adsorbent.

Embodiment 2

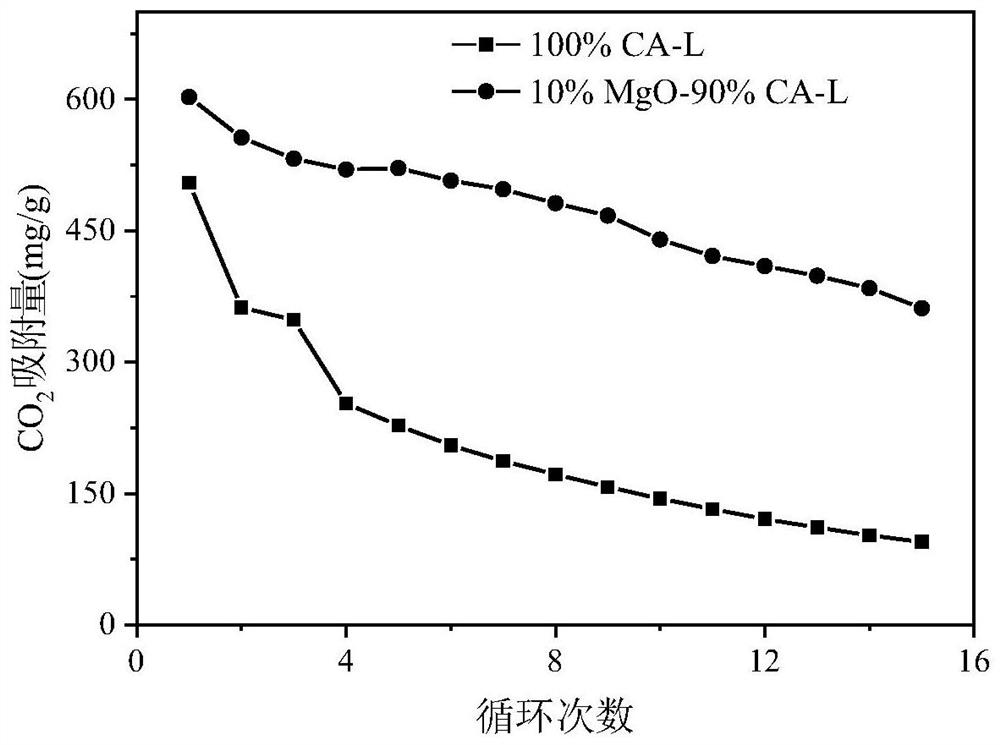

[0053] This example provides a CO based on multi-source solid waste modification 2 The preparation method of adsorbent, described preparation method comprises the following steps:

[0054] (1) Limestone was immersed in 1mol / L NaCl solution for 2 hours, calcined at 1000°C at a heating rate of 5°C / min for 2h, and then ball milled at a speed of 300r / min for 25min to obtain an adsorbent;

[0055] (2) MgO was dried at 130° C. for 2 h, ball milled at 300 r / min for 25 min, 1 g of MgO after ball milling was mixed with 9 g of the adsorbent described in step (1), and the obtained mixture was ball milled at 300 r / min for 25 min, Then calcined at 800°C for 2h at a heating rate of 5°C / min to obtain the CO 2 Adsorbent.

Embodiment 3

[0057] This example provides a CO based on multi-source solid waste modification 2 The preparation method of adsorbent, described preparation method comprises the following steps:

[0058] (1) Limestone was immersed in 1mol / L KCl solution for 3 hours, calcined at 900° C. for 2 hours at a heating rate of 3° C. / min, and then ball milled at 400 r / min for 20 minutes to obtain an adsorbent;

[0059] (2) Al 2 o 3 Dry at 125°C for 2 hours, ball mill at 400r / min for 20 minutes, and 1g of Al after ball milling 2 o 3 Mixed with 9g of the adsorbent described in step (1), the obtained mixture was ball milled at 400r / min for 20min, and then calcined at 850°C for 2h at a heating rate of 3°C / min to obtain the CO 2 Adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com