Carriage lorry-mounted crane

A technology of truck-mounted cranes and carriages, which is applied to cranes, freight vehicles, motor vehicles, etc., can solve problems such as low loading and unloading efficiency, and achieve the effect of avoiding load operation and arranging neatly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

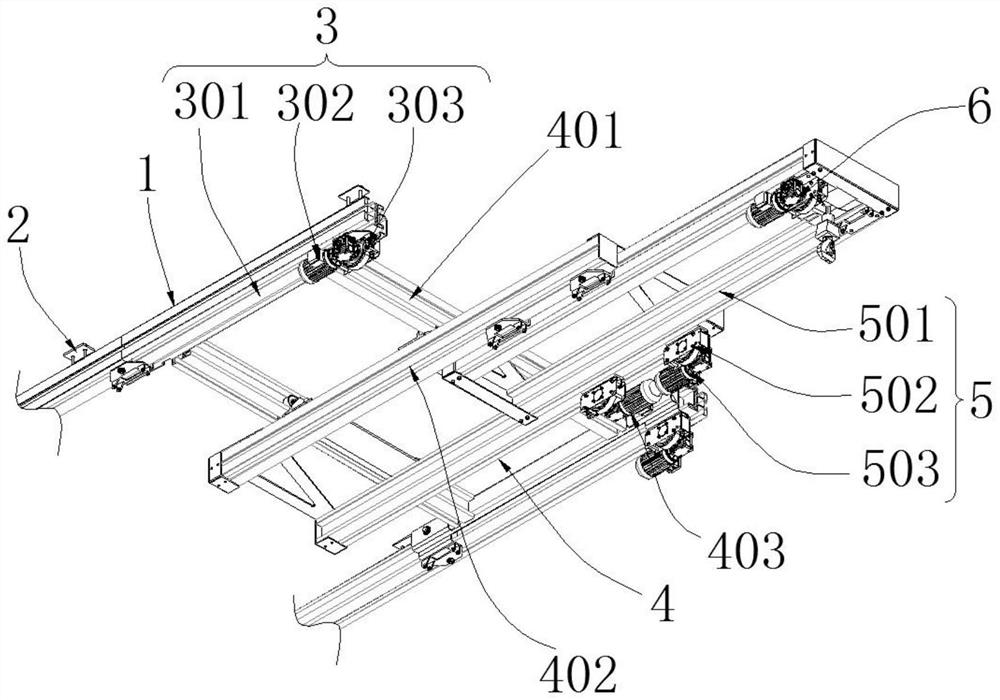

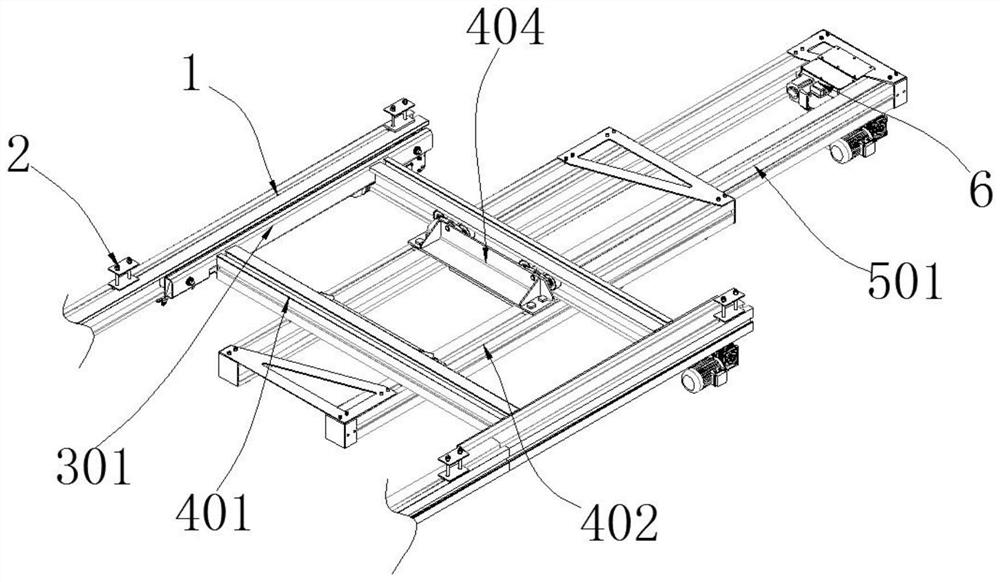

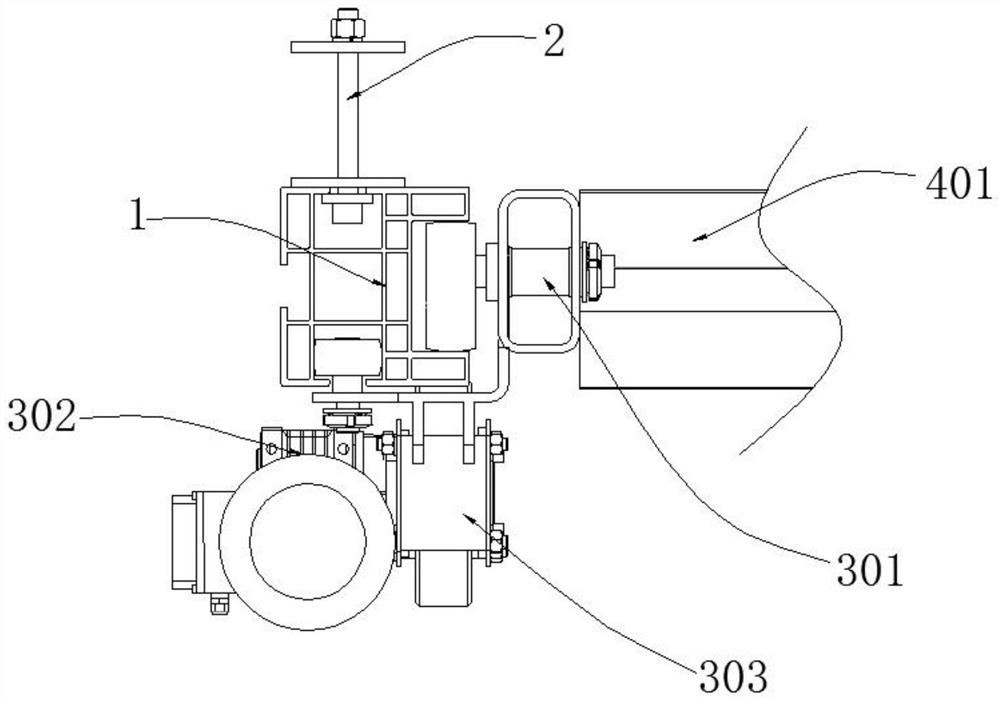

[0033] Embodiment two, such as Figure 4-5 As shown, when it is necessary to load goods on the side of the compartment, the side of the compartment is opened, and the first-stage arm 402 and the beam rail 401 are distributed in parallel up and down. At the same time, two or three sets of basic components are configured according to the length of the object Level 4, level 5 and chain hoist 6;

[0034] Take three groups as an example, three groups of basic components 3, primary components 4, secondary components 5 and chain hoists 6, two of which are located at both ends of the compartment respectively, and the third group is located in the middle of the compartment, specifically by the first motor 302 Drive the first deceleration wheel 303 to slide inside the aluminum alloy track 1, so that the base arm 301 reaches the front end, middle section and tail end of the aluminum alloy track 1;

[0035] Then the secondary arm 501 drives the third deceleration wheel 502 through the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com