Construction method of FQY + TU-JS basement waterproof system

A TU-JS and construction method technology, applied in infrastructure engineering, protective devices, buildings, etc., can solve the problems of groundwater seeping into the room, abandonment of underground projects, and shortened life, so as to reduce corrosion, save construction period, and reduce materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

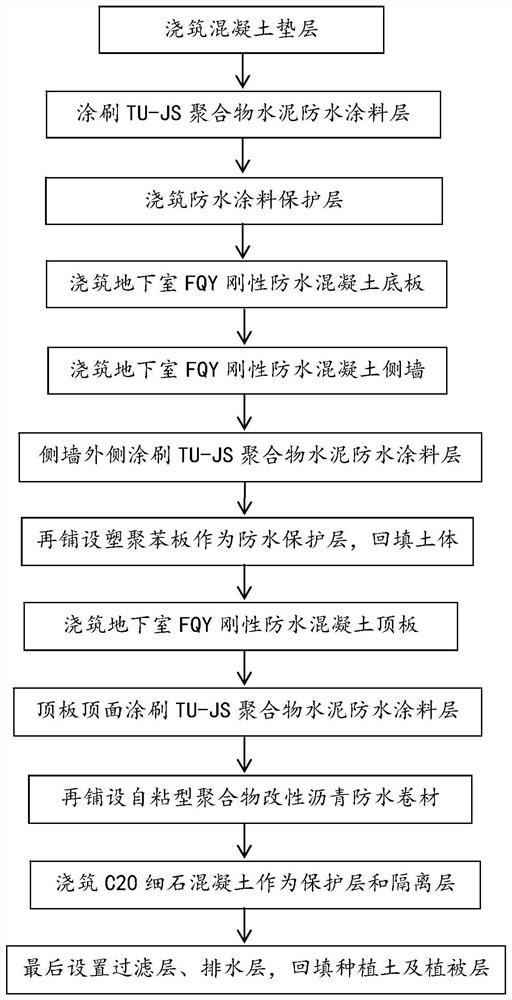

[0013] The construction method of the FQY+TU-JS basement waterproof system provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] Now take a residential building project in a residential area as an example to illustrate: the project has a total of 15 residential buildings (4 buildings 18F, 6 buildings 17F, 5 buildings 11F), 1 public toilet, 1 police room, 1 elderly care service facility, 1 community service center and 2 commercial buildings; the height of the residential buildings is 2.9m, and the height of the basement is 3.9m; The high-rise structure is a shear wall structure, and the underground garage is a frame structure; the first basement of the main building is a storage room, and the second basement is a civil air defense. The applicant adopts the method of the present invention to control the waterproof construction of the basement waterproof system, and the effect is excell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com