Novel automobile oil pump driving shaft and machining process thereof

A processing technology and drive shaft technology, which is applied in the field of new-type automobile oil pump drive shaft and its processing technology, can solve problems such as misalignment, affecting the performance of the drive shaft, and the drive shaft is susceptible to wear, so as to ensure accuracy and improve The service life and the effect of improving the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

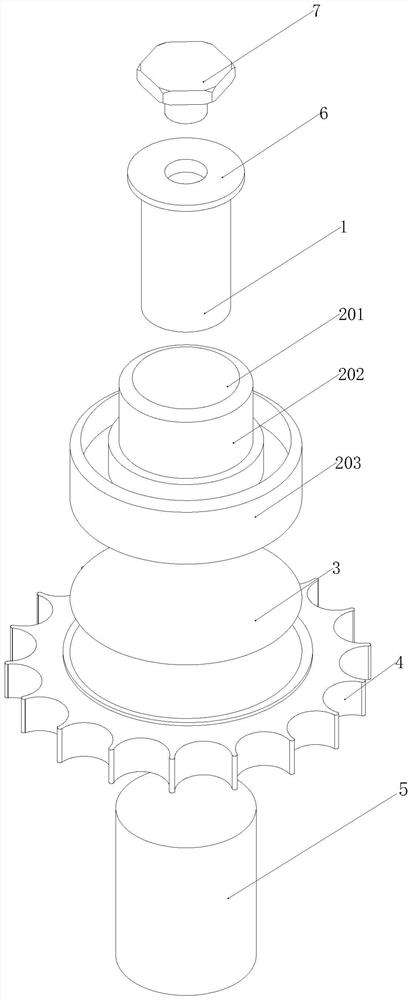

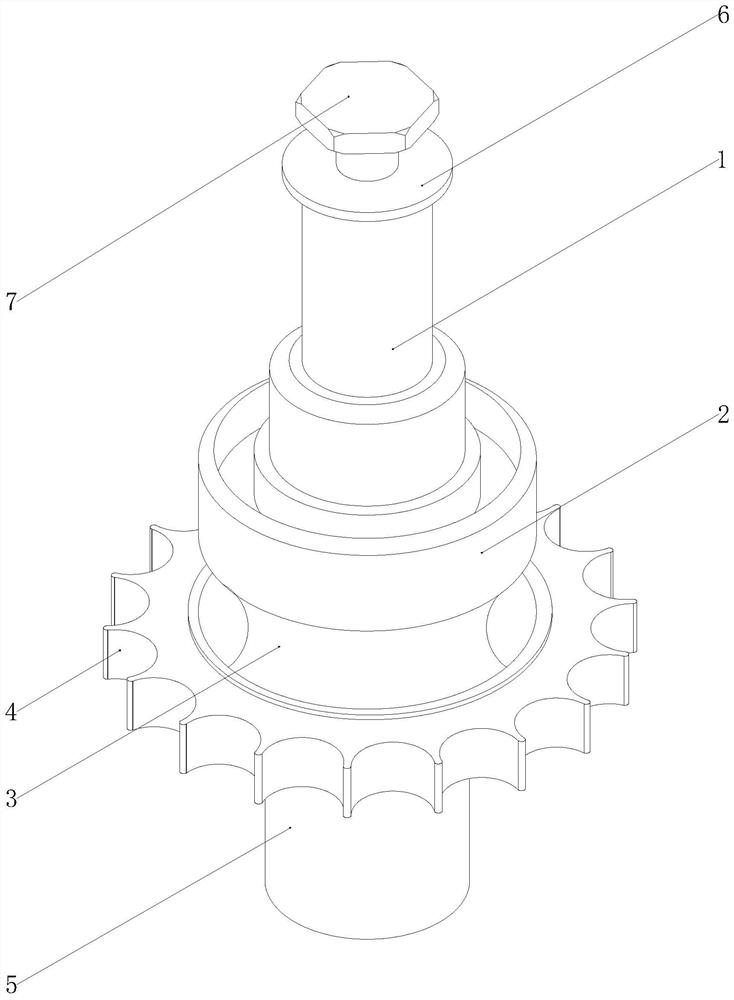

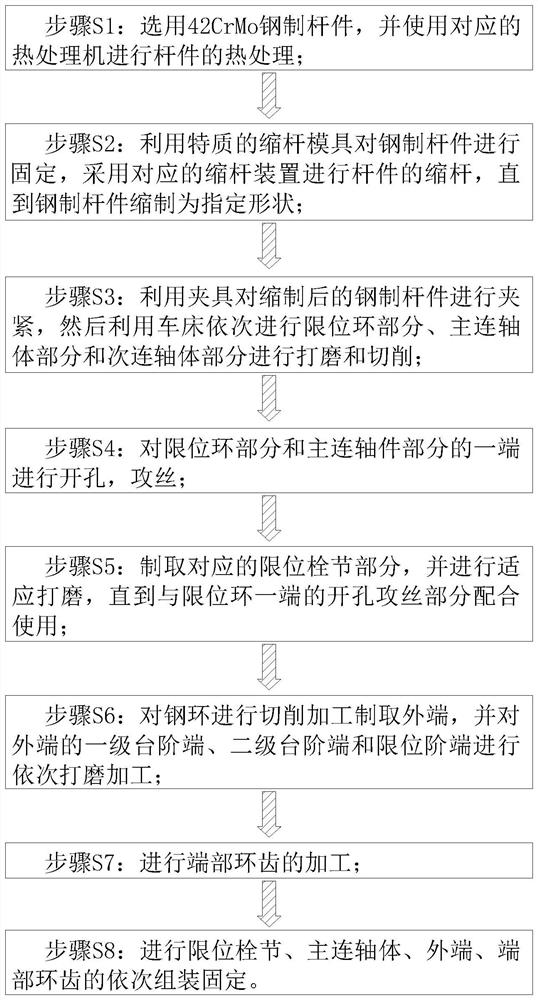

[0041] Example: such as Figure 1-3 As shown, a new type of automobile oil pump drive shaft in the present invention includes a main coupling body 1, an outer end 2 is sleeved in the middle of the outer surface of the main coupling body 1, and an inner arc-shaped joint 3 is fixedly connected to the bottom of the outer end 2. , the outer side of the bottom end of the inner arc-shaped section 3 is provided with an end ring tooth 4, the bottom end of the inner arc-shaped section 3 is fixedly connected with the secondary shaft body 5, and the top end of the main shaft body 1 is fixedly connected with the limit ring 6, The top end of the limiting ring 6 is threadedly connected to the limiting bolt 7 through a screw hole.

[0042] Among them, both the main shaft body 1 and the secondary shaft body 5 are made of 42CrMo steel, and the outer ring diameter of the main shaft body 1 is smaller than the outer ring diameter of the secondary shaft body 5, and the main shaft body 1 and the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com