Cable connector and connector assembly

A cable connector and cable technology, which is applied to parts, connections, and fixed connections of connecting devices, can solve problems affecting product signal integrity, signal interference, etc., to save space on the motherboard, improve reliability, and reduce size. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

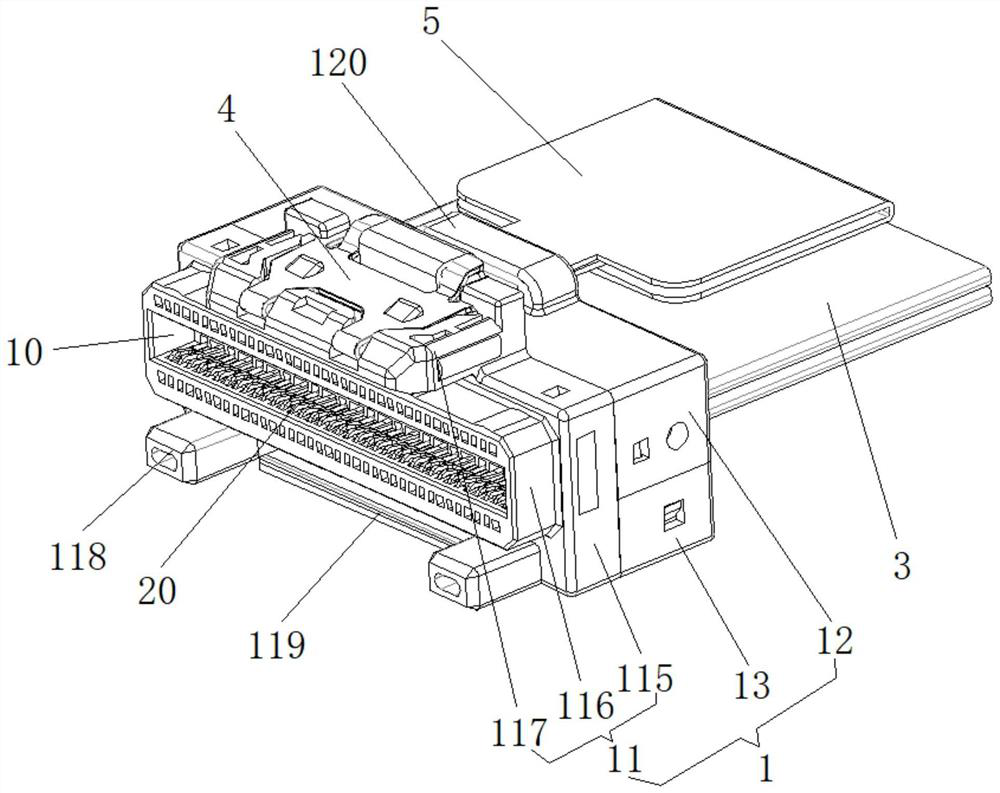

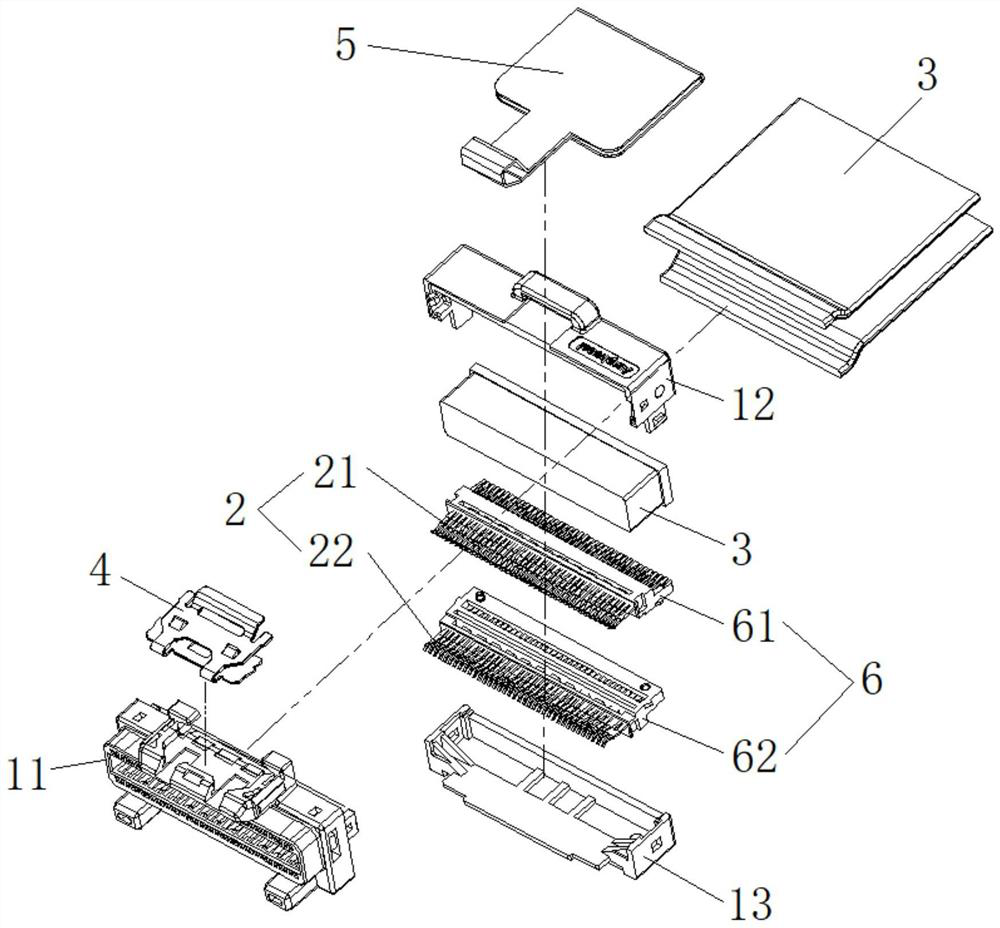

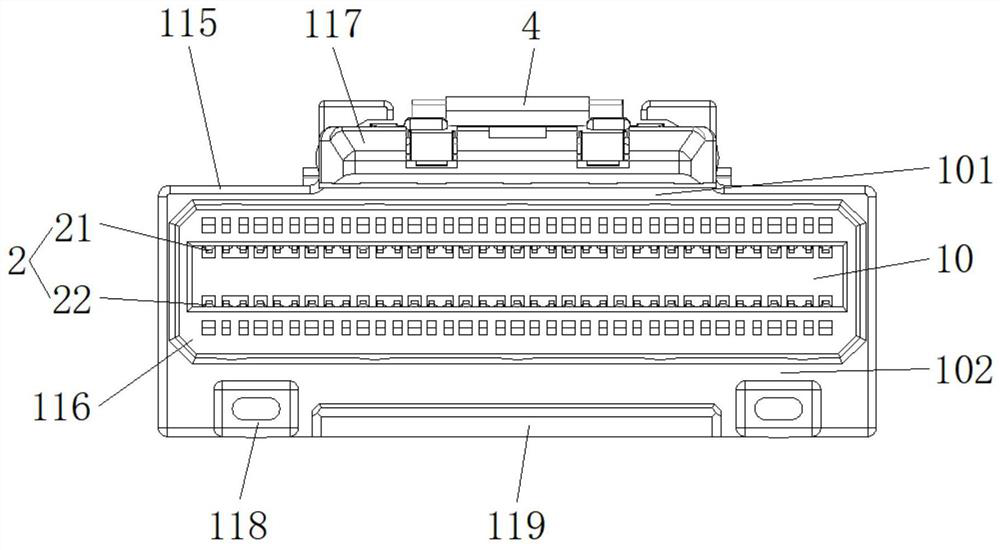

[0045] Figure 1-12As shown, a cable connector includes a housing 1, a conductive terminal group 2 disposed inside the housing 1, a cable 3 electrically connected to the conductive terminal group 2, and a locking member 4 installed on the top of the housing 1 And the drawstring 5 that is connected with the buckle 4. The front end of the housing 1 is provided with a socket slot 10, and the conductive terminal group 2 includes a first terminal row 21 and a second terminal row 22 symmetrically arranged on the upper and lower sides of the socket slot 10, and the first terminal row 21 and the second terminal row 22 are composed of several conductive terminals 20 arranged along the width direction of the socket slot 10 . The conductive terminal 20 includes a main body 201, a contact portion 202 bent from the front end of the main body 201, and a welding portion 203 extending backward from the rear end of the main body 201. The welding portion 203 of the first terminal row 21 and th...

Embodiment 2

[0055] Such as Figure 13 , Figure 14 As shown, a connector assembly includes a cable connector and a board connector 8, and the cable connector is the cable connector in the first embodiment. The board end connector 8 includes an insulating body 81 , a tongue 82 fixed inside the insulating body 81 for contacting and mating with the conductive terminal group of the cable connector, and a shell 83 sleeved outside the insulating body 81 . Preferably, the bottom of the housing 83 is bent to form a limiting groove 830 , and the limiting block 119 at the front end of the housing 1 of the cable connector is inserted into the limiting groove 830 for positioning.

[0056] In this embodiment, the thickness of the tongue 82 of the board end connector 8 is 2 mm, and the minimum distance h between the contact portion 202 of the first terminal row 21 of the cable connector and the contact portion 202 of the second terminal row 22 is 1.4 mm. ~2 mm, and the distance H between the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com