Nitrogen spring intelligent monitoring system based on Internet of Things and operation method

A nitrogen gas spring, intelligent monitoring technology, used in springs, transmission systems, springs/shock absorbers, etc., can solve the problems of inconvenient installation of nitrogen gas springs, incomplete parameters, unstamped times, and stamping frequency monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

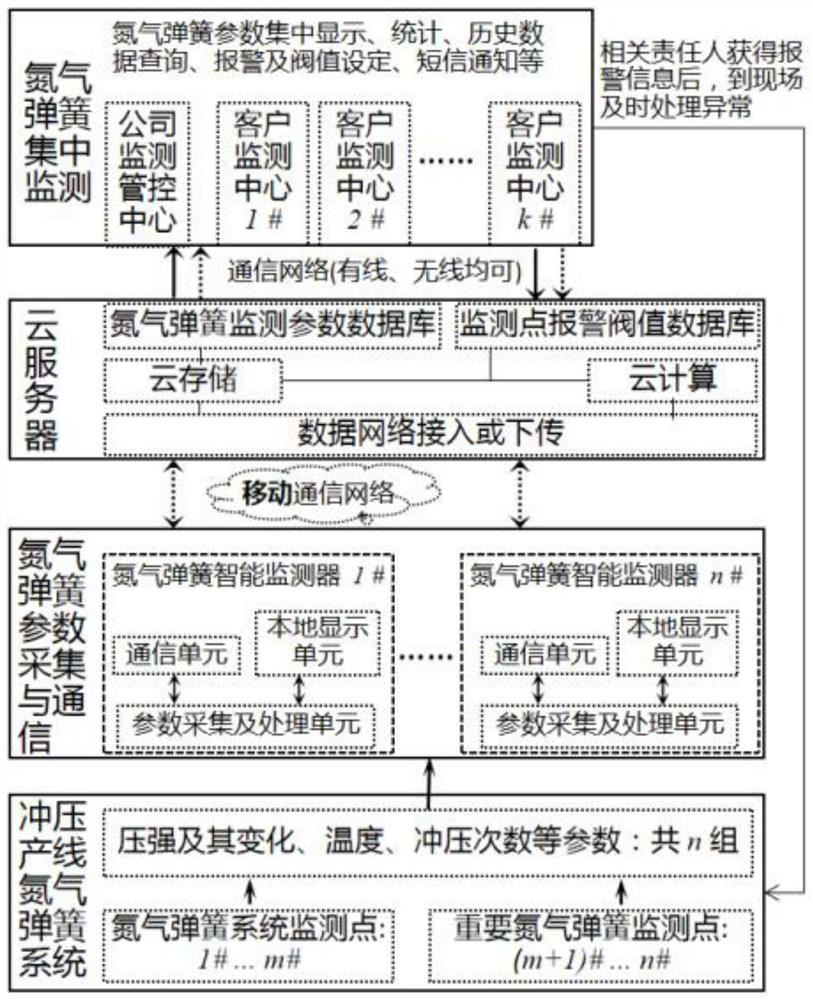

[0051] An intelligent monitoring system for nitrogen springs based on the Internet of Things, including: a stamping production line nitrogen spring system module, a nitrogen spring parameter acquisition and communication module, a cloud server module, and a nitrogen spring centralized monitoring module, wherein:

[0052] There are n groups of nitrogen spring system modules in the stamping production line, which are distributed in each set of molds in the production line after stamping. The nitrogen springs are connected through high-pressure pipelines, and finally the integrated control block in the system is led out to the mold for easy inflation and deflation. , Pressure adjustment and other operations and observation positions.

[0053] The nitrogen spring parameter acquisition and communication module is composed of n nitrogen spring intelligent monitors, which are respectively installed on the corresponding interfaces of the integrated control block, and the high-pressure ...

Embodiment 2

[0057] As a further optimization of the above embodiment: an intelligent monitoring system for nitrogen springs based on the Internet of Things, including: a stamping production line nitrogen spring system module, a nitrogen spring parameter acquisition and communication module, a cloud server module, and a nitrogen spring centralized monitoring module, wherein:

[0058] There are n groups of nitrogen spring system modules in the stamping production line, which are distributed in each set of molds in the production line after stamping. The nitrogen springs are connected through high-pressure pipelines, and finally the integrated control block in the system is led out to the mold for easy inflation and deflation. , Pressure adjustment and other operations and observation positions.

[0059] The nitrogen spring parameter acquisition and communication module is composed of n nitrogen spring intelligent monitors, which are respectively installed on the corresponding interfaces of t...

Embodiment 3

[0063] As a further optimization of the above embodiment: an intelligent monitoring system for nitrogen springs based on the Internet of Things, including: a stamping production line nitrogen spring system module, a nitrogen spring parameter acquisition and communication module, a cloud server module, and a nitrogen spring centralized monitoring module, wherein:

[0064] There are n groups of nitrogen spring system modules in the stamping production line, which are distributed in each set of molds in the production line after stamping. The nitrogen springs are connected through high-pressure pipelines, and finally the integrated control block in the system is led out to the mold for easy inflation and deflation. , Pressure adjustment and other operations and observation positions.

[0065] The nitrogen spring parameter acquisition and communication module is composed of n nitrogen spring intelligent monitors, which are respectively installed on the corresponding interfaces of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com