Multi-stage centralized powder material feeding equipment and method

A powder material, centralized technology, applied in the direction of conveying bulk materials, conveyor objects, conveyor control devices, etc., can solve the problems of reducing equipment sealing, increasing dust leakage, and difficult to realize intensive management of personnel and equipment. To achieve the effect of guaranteed feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

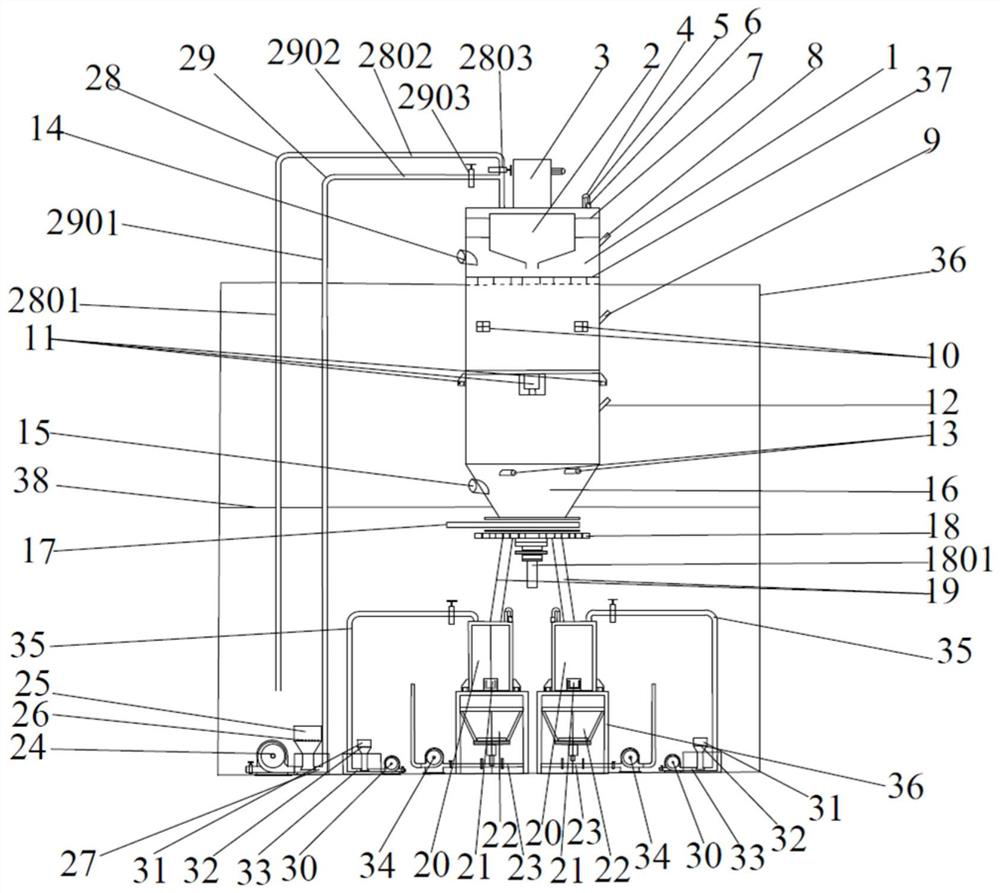

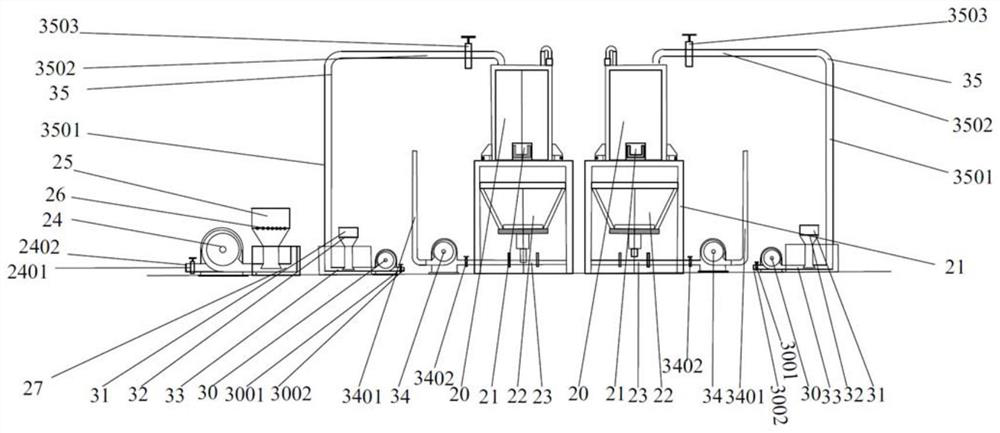

[0043] Such as figure 1 , 2 As shown, a multi-stage centralized powder material feeding equipment, a silo storage unit, a conveying unit, a weighing unit, and a control unit; wherein the silo storage unit includes a primary silo 1 and a secondary silo 20 The conveying unit includes a primary conveying system connected to the primary silo 1 and a secondary conveying system connected to the secondary silo 20; the metering and weighing unit includes a load cell-11 arranged in the primary silo 1 and the load cell 2 21 set in the secondary silo 20; also includes the level meter set in the primary silo 1; the control unit is connected with the conveying unit and the metering and weighing unit respectively.

[0044] The feeding equipment also includes a metal frame 36; wherein the primary silo 1 and the secondary silo 20 are all set on the metal frame 36; the top of the primary silo 1 is provided with a cloth bag 2, and the cloth bag 2 is connected to the primary material through th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap