Bagged cement unloading robot

A robot and cement technology, applied in loading/unloading, manipulators, conveyors, etc., can solve the problems of limited strength of packaging bags, small size of cement powder, dust, etc., to achieve good suction and collection effect, uniform contact surface, guarantee The effect of air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

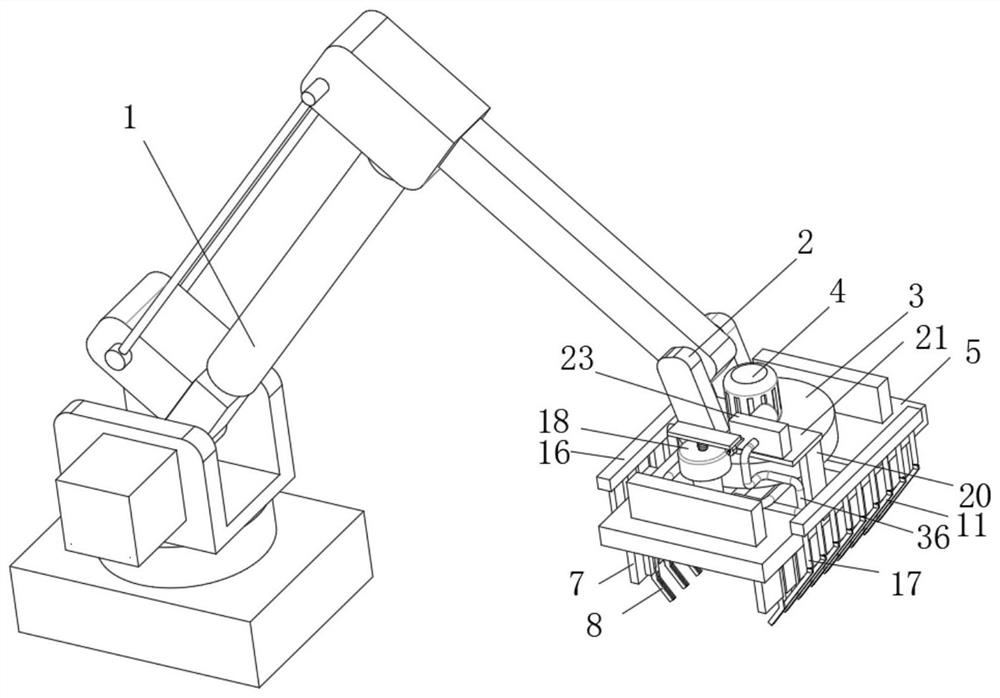

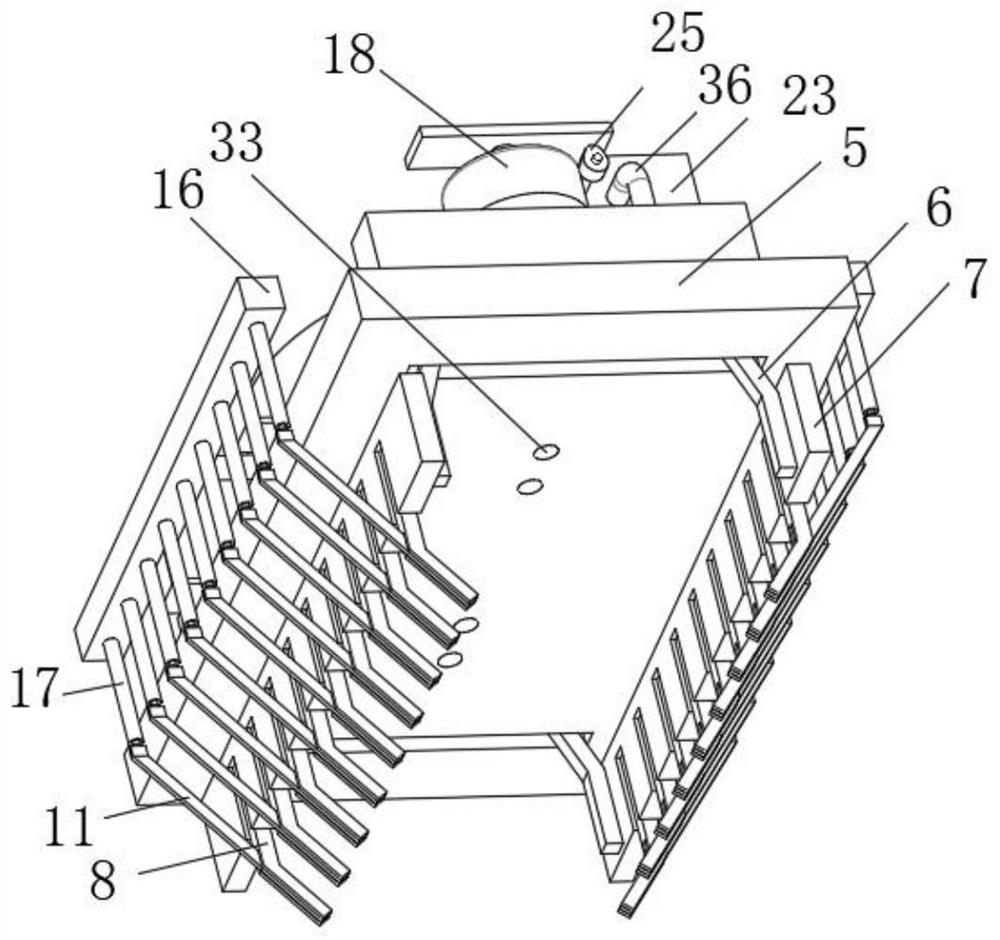

[0039] The first embodiment: as figure 1 , figure 2 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, when unloading and stacking, the main body of the robot 1 moves so that the base 5 is close to the bagged cement downwards, and the existing pneumatic control box on the top surface of the mounting seat 3 is used to push the existing pneumatic control box to push the The angle of movement of the control clip 6 swings, so that the control clips 6 on both sides drive the installation plate 7 to swing, and then the bottoms of the jaws 8 installed on both sides are moved closer and tilted to hold the bagged cement from the bottom of the bagged cement, so that the jaws 8 are tilted Clamp the side of the bagged cement, and keep the bagged cement at the top of the side of the jaw 8, complete the clamping, start the power motor 22, so that the power motor 22 drives the rotating shaft 24 to rotate, and at the same time make the cam 25 on the outer surface of the rotating...

no. 2 example

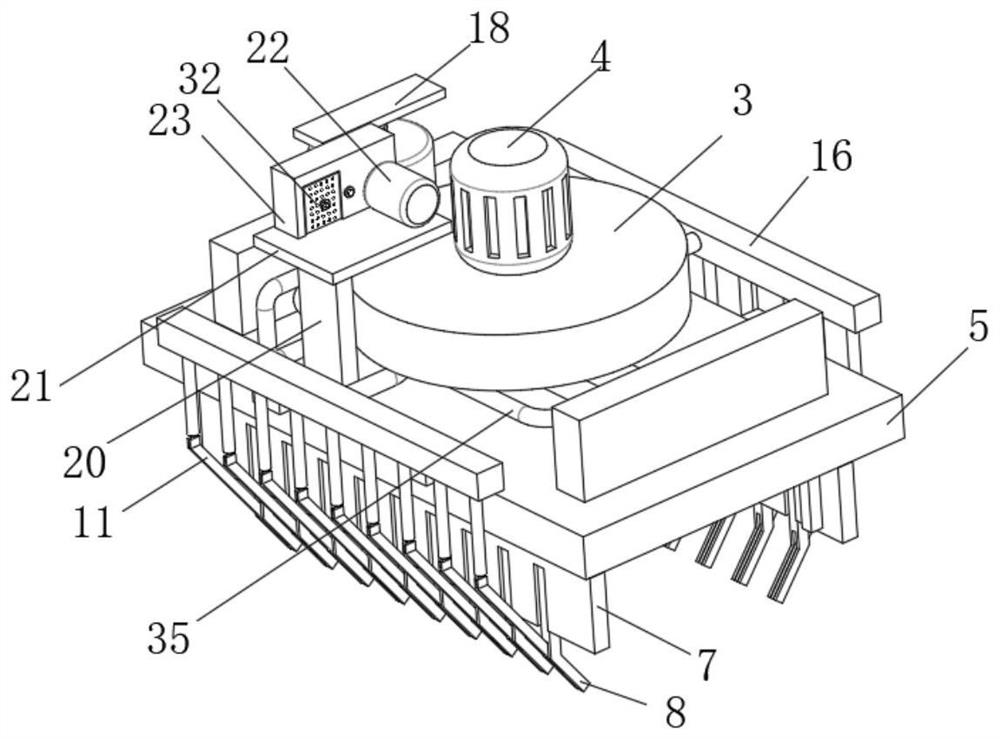

[0046] The second embodiment: as figure 1 , image 3 , Figure 4 , Figure 8 with Figure 9 As shown, when the robot grabs bagged cement, while the power motor 22 drives the rotating shaft 24 to rotate, the second gear 30 on the outer surface of the rotating shaft 24 drives the first gear 28 on the outer surface of the mounting shaft 27 to rotate, which is relatively The larger No. 2 gear 30 drives the smaller No. 1 gear 28 to rotate at a high speed. With the high-speed rotation of the No. 1 gear 28, the installation shaft 27 drives the blade 29 to rotate, and then the air inside the No. 3 pipe 36 is sucked into the fixed box 23, As the power motor 22 rotates, multiple sets of swing rods 11 beat the bagged cement repeatedly, so that the auxiliary cement powder on the surface of the bagged cement vibrates and is sucked into two sets of suction sleeves 34 through the suction holes 33, and rotates with the blades 29. Air is sucked, and the cement powder in the two sets of suc...

no. 3 example

[0051] The third embodiment: as figure 1 , Figure 4 , Figure 8 with Figure 9 As shown, after the cement powder is gradually sucked in the fixed box 23, the robot completes the unloading work, and the locking cap 324 is unscrewed from the fixed rod 321 from the side of the fixed box 23, and the filter plate 323 is taken off outwardly. Manually sweep the cement powder on the filter hole of the filter plate 323 and the side into the external storage box, and gently sweep out the cement powder in the fixed box 23 through the installation port 31 on the side of the fixed box 23, and sweep it out The cement powder is placed in the storage box, and the cleaning and cleaning are completed.

[0052] First, use the power motor 22 to drive the rotation shaft 24 to rotate, so that the cam 25 rotates, and the second gear 30, which has a number of teeth much larger than the number of teeth of the first gear 28, drives the first gear 28 to rotate, so that the first gear 28 drives the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com