Chromic acid recycling treatment device for hard chromium plating production line

A production line of chromic acid, recycling technology, applied in the direction of filtration, special treatment, heating water/sewage treatment, etc., can solve the problems of impracticality, filter damage, etc., to save working time, easy to take out and disassemble and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

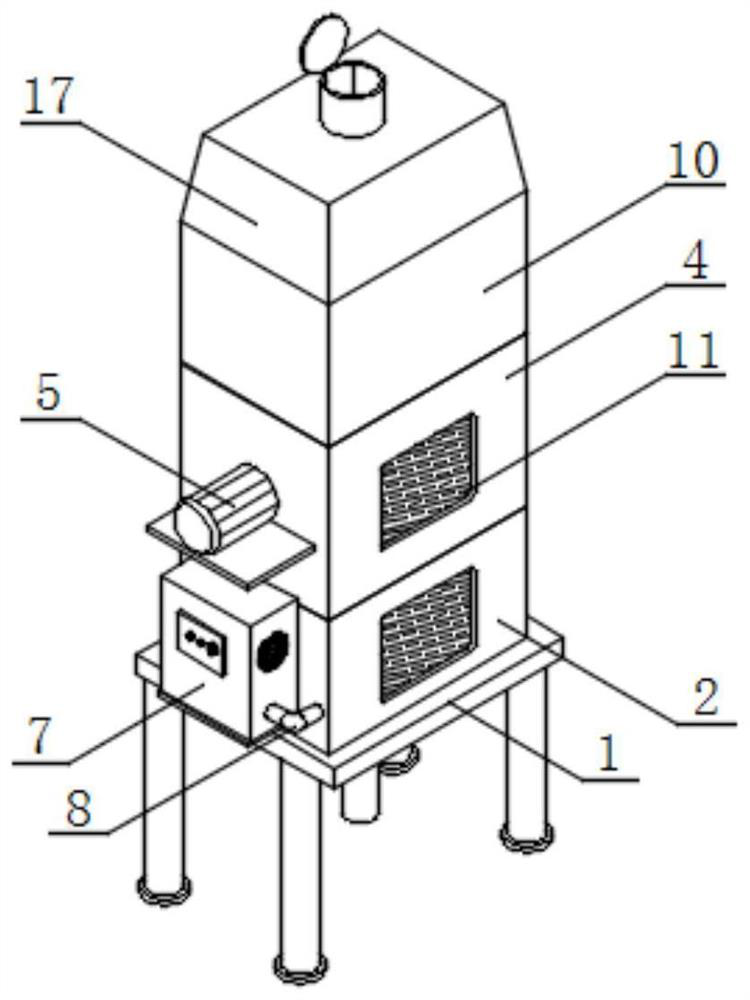

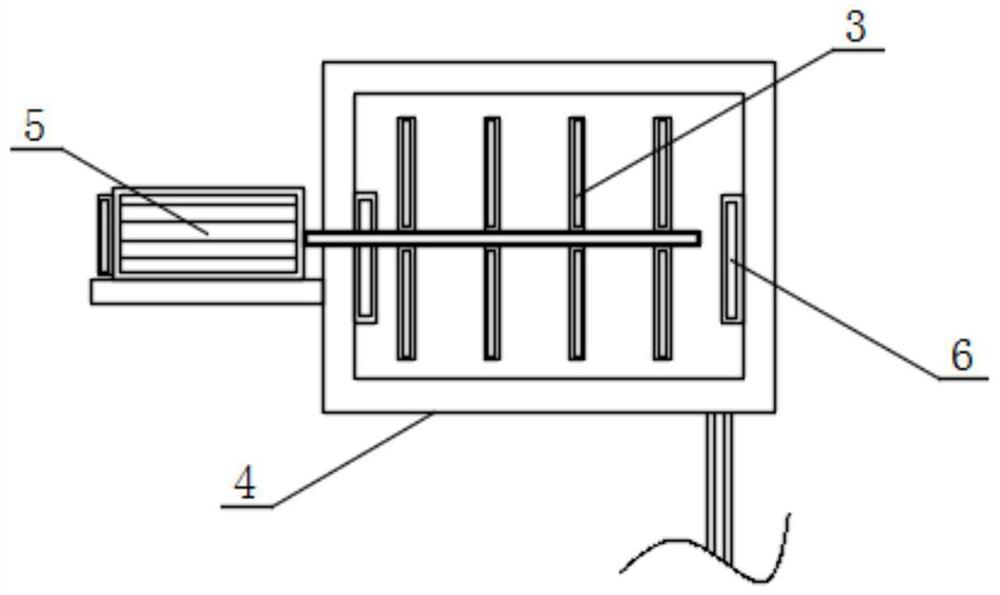

[0029] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , an embodiment provided by the present invention, a chromic acid recycling treatment device for a hard chromium plating production line, comprising a support frame 1, a disinfection chamber 2 and a stirring blade 3, a disinfection chamber 2 is arranged on the top of the support frame 1, and a disinfection chamber 2 The top of the heating chamber is provided with a heating chamber 4, the surface of the heating chamber 4 is provided with a support base, the top of the support base is provided with a driving motor 5, the output end of the driving motor 5 is provided with a stirring rod, and the surface of the stirring rod is provided with several stirring blades 3 , the inner wall of the heating chamber 4 is provided with a group of heaters 6, the bottom of the heating chamber 4 is provided with an infusion tube a, the surface of the disinfection chamber 2 is provided with a fixed seat, and the top of the f...

Embodiment 2

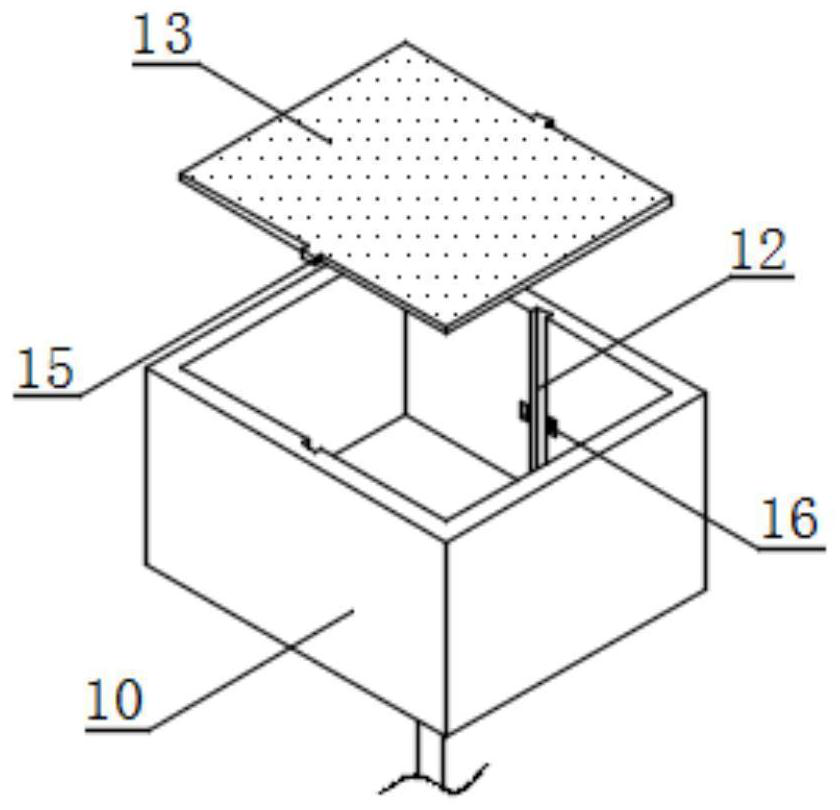

[0031] see figure 1 with figure 2 , an embodiment provided by the present invention, a chromic acid recycling treatment device for a hard chromium plating production line, comprising a filter screen 13, a compression spring 14 and an insertion rod 15, the top of the heating chamber 4 is provided with a filter chamber 10;

[0032] Filter chamber 10, heating chamber 4, disinfection chamber 2, driving motor 5, stirring blade 3, heater 6, ozone generator 7, gas delivery pipe 8 and ultraviolet lamp 9 are set, and the staff feeds the chromic acid solution through the feed port Add the inside of the filter chamber 10, so that the chromic acid solution passes through the filter screen 13 to filter out some impurities inside, and then enter the inside of the heating chamber 4 through the infusion tube b after filtering the chromic acid solution, and start the drive motor 5 and the heater 6 at this time , the output end of the drive motor 5 drives the stirring rod to rotate, because t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com