Reversible photochromic transparent ceramic as well as preparation method and application thereof

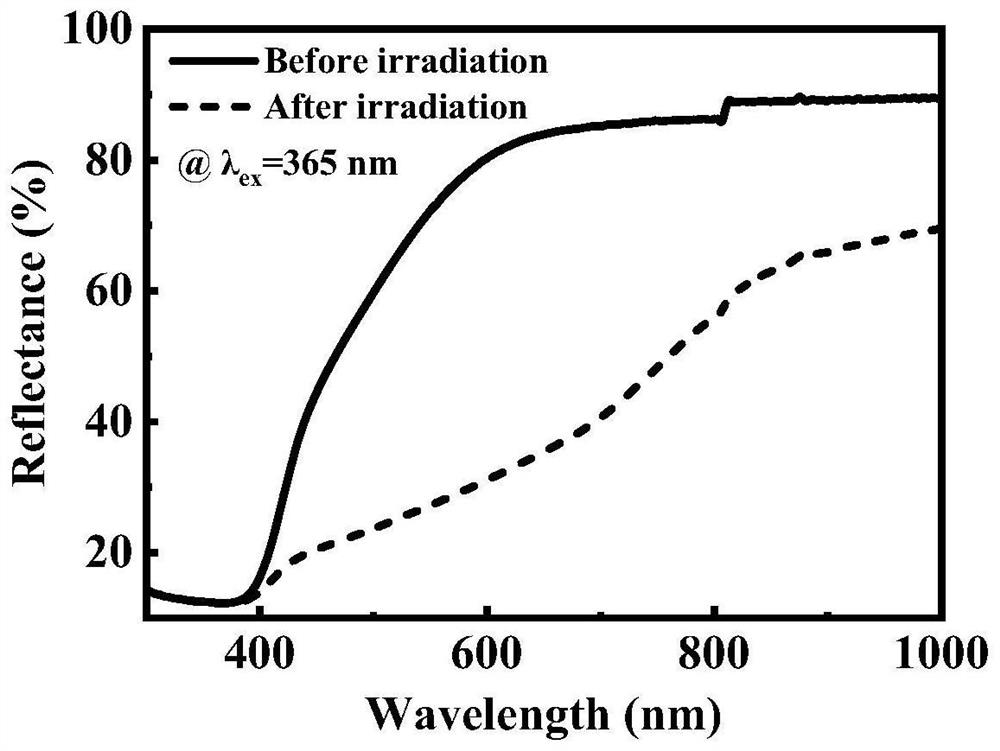

A transparent ceramic and photochromic technology, applied in the field of ceramic materials, can solve the problems of inability to be used in the field of smart windows, slow response, non-transparency of photochromic ceramics, etc., to achieve fast response time, high stability, and high discoloration contrast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a method for preparing any one of the above-mentioned reversible photochromic transparent ceramics, comprising the following steps:

[0051] According to the chemical composition, Ba source, A source, Mg source and B source are mixed with additives for grinding, and then calcined, shaped and sintered.

[0052] In a specific embodiment of the present invention, the A source is selected from ZrO 2 , SnO 2 、TiO 2 and HfO 2 At least one of; the B source is selected from Ta 2 o 5 and Nb 2 o 5 At least one of: the Ba source is barium carbonate, and the Mg source is magnesium oxide.

[0053] In a specific embodiment of the present invention, the auxiliary agent includes a dispersant, a binder and a sintering auxiliary agent. In actual operation, the type and amount of dispersant, binder and sintering aid can be adjusted according to actual needs. Existing conventional additives can be selected to achieve the corresponding conventiona...

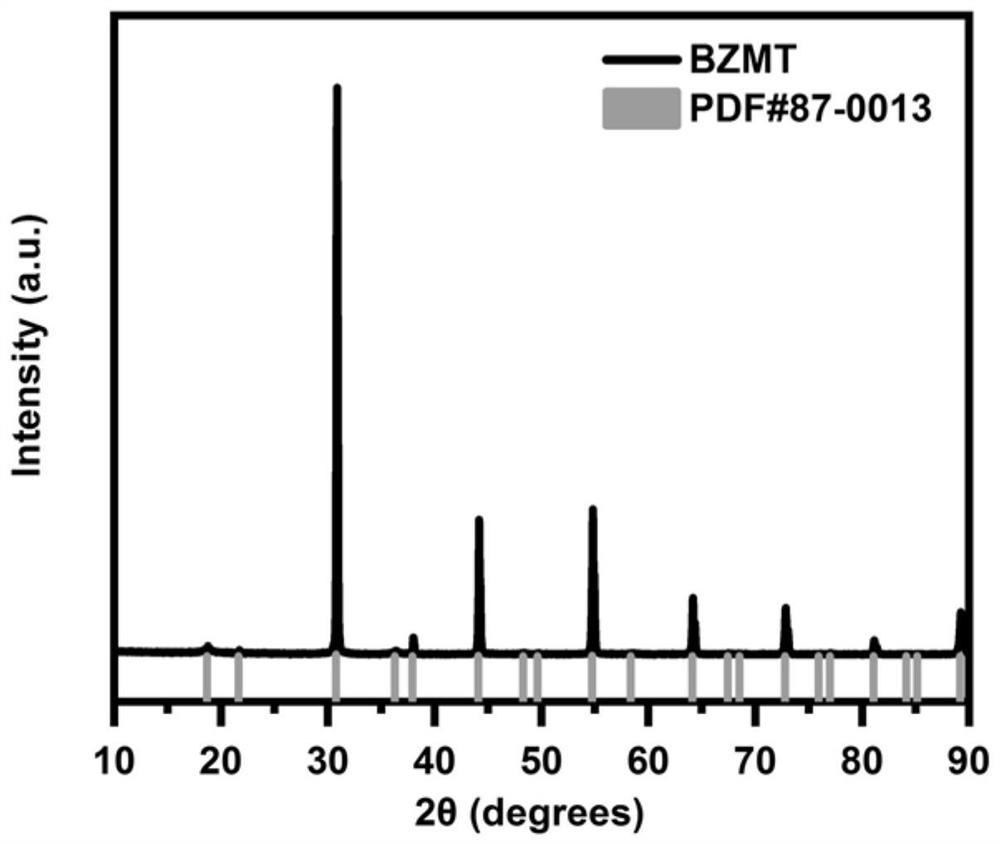

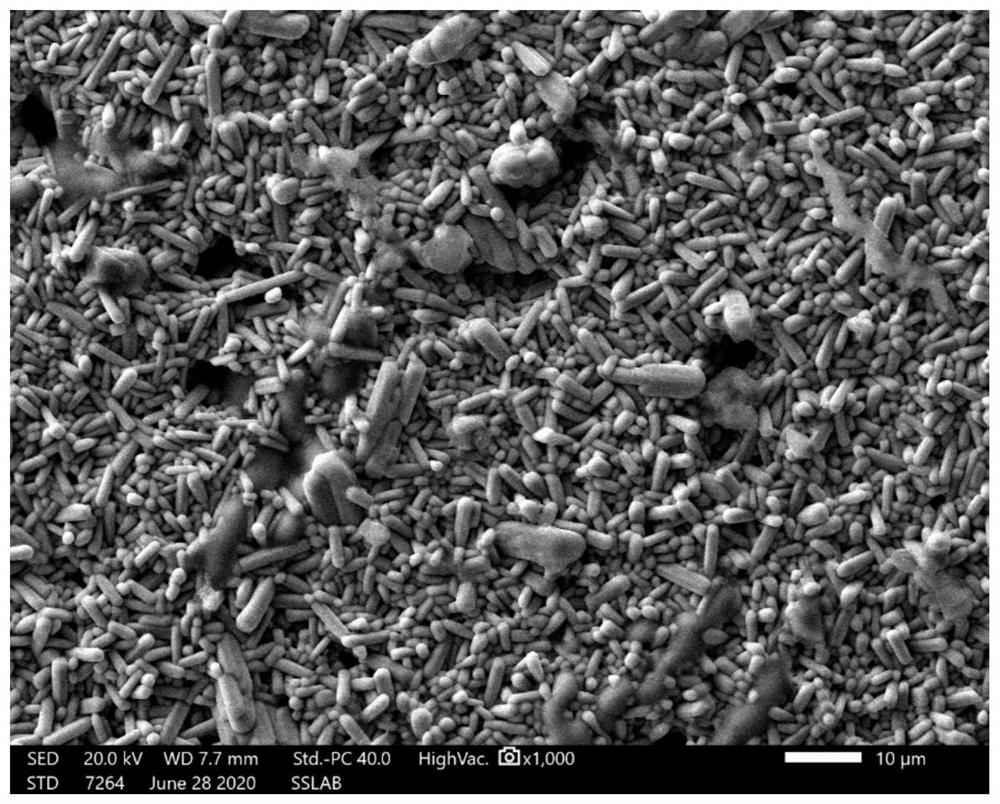

Embodiment 1

[0063] This embodiment provides a method for preparing a reversible photochromic transparent ceramic, including the following steps:

[0064] (1) Press Ba(Zr 0.16 Mg 0.28 Ta 0.56 )O 3 The stoichiometric weighing of BaCO 3 , ZrO 2 , MgO, Ta 2 o 5 (The molar ratio of Ba, Zr, Mg, Ta is 1: 0.16: 0.28: 0.56) to obtain the mixed powder, add 0.5%, 1% and 0.5% of the mass of the mixed powder respectively dispersant oleic acid, binder polymer Vinyl butyral and tetraethyl orthosilicate as a sintering aid to obtain a mixed material; then add ethanol 1.2 times the mass of the mixed material, and add zirconia balls according to the ball-to-material ratio of 1:3 (the weight ratio of large and small balls is 1:1 , the size of the large ball is 10 mm, and the size of the small ball is 5 mm), all of which are placed in a polytetrafluoroethylene ball mill tank, and the ball mill is treated for 24 hours to obtain a mixed slurry.

[0065] (2) Then, suck the slurry and dry it in an oven at...

Embodiment 2

[0068] This embodiment provides a reversible photochromic transparent ceramic Ba(Sn 0.16 Mg 0.28 Ta 0.56 )O 3 The preparation method, the specific steps refer to Example 1, the only difference is that the ZrO in the step (1) 2 Replaced by SnO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com