Method for preparing citronellol from hydrogenated citral

A technology of citral and citronellol, which is applied in the field of hydrogenated citral preparation, can solve the problems that common catalysts cannot achieve effects, affect product yield and production efficiency, shorten the life of catalysts, etc. Rapid, selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

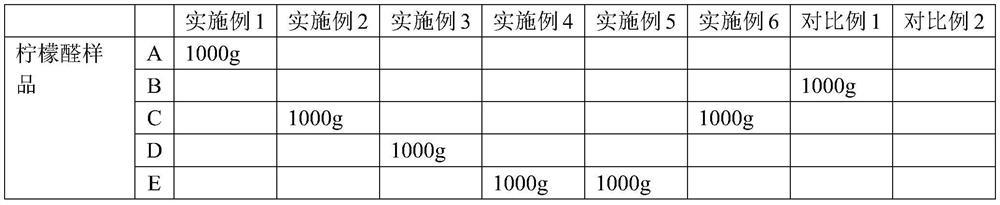

[0047] Preparation of citral raw materials with different metal ion contents

[0048] Add metal ion compound to the citral obtained by the above preparation and stir evenly to obtain citral raw material sample A, sample B, sample C and sample D of different metal ion content, add complexing agent ethylenediaminetetraacetic acid to sample B To reduce the metal ion content in citral, the test results are as follows.

[0049]

preparation example

[0051]Metal cobalt, nickel, molybdenum and aluminum are fused at high temperature according to the mass ratio of 25%, 30%, 5% and 40% respectively, the alloy is cooled to room temperature, pulverized, and alloy particles of 50-400 mesh are screened. Prepare 500 g of sodium hydroxide solution with a concentration of 20%, boil it, slowly add 100 g of alloy particles, continue to boil for 4 hours, and cool. Pour off the gray upper layer of turbid liquid, add water and wash it repeatedly at room temperature for 3 times. After standing still, the liquid layer is clear and transparent, and the pH value is less than 10. The prepared M2 catalyst has a cobalt content of 31% and a nickel content of 37% as detected by ICP, and is stored under the liquid level of the water seal for future use.

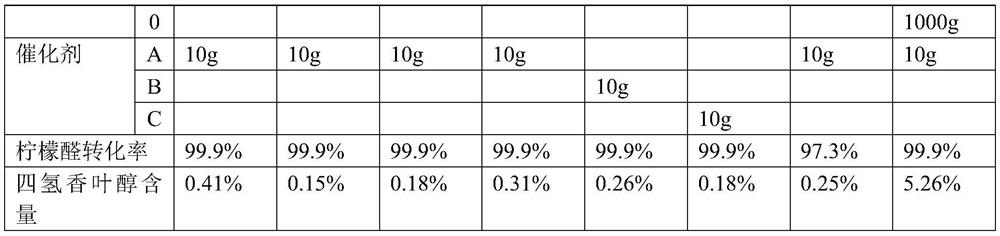

Embodiment

[0053] Transfer a certain amount of catalyst and citral to the autoclave, use nitrogen to replace the gas in the autoclave three times, use hydrogen to replace the nitrogen in the autoclave, adjust the hydrogen pressure to 3MPaA, start stirring, raise the temperature to 50°C for 5 hours, and use gas chromatography The conversion rate of citral was measured, and the citronellol product was obtained after removing the catalyst by filtration.

[0054]

[0055]

[0056] It can be seen from the above examples and comparative examples that when the metal ion content in the citral raw material is controlled within the range of 10ppm-100ppm, the catalyst activity can be adjusted to reduce excessive hydrogenation and improve selectivity.

[0057] Application example of catalyst

[0058] Repeat the conditions of Example 2, Example 4, Comparative Example 1 and Comparative Example 2, filter and recover the catalyst and apply mechanically, the reaction results are as follows:

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com