Thermal jet natural gas hydrate exploitation device, system and method

A natural gas and hydrate technology, which is applied in the fields of mining fluids, drilling equipment and methods, earthwork drilling, etc., can solve the problems of limited heating mining range, low energy efficiency, environmental pollution, etc., to ensure continuity and stability, Avoid freezing and clogging, high mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

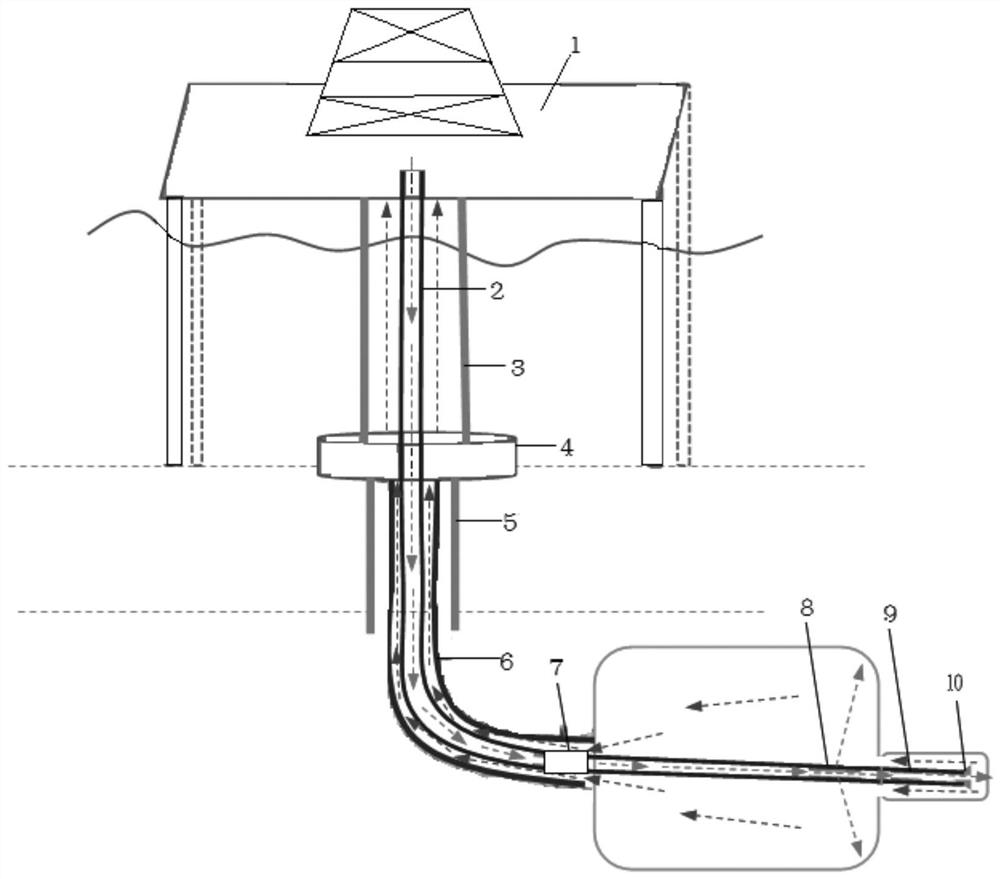

[0038] like figure 1 As shown, the present invention provides a thermal jet natural gas hydrate extraction device, which includes a coiled tube 2 capable of rotating and drilling in the natural gas hydrate layer. When the coiled tube 2 is rotating, it sprays hot water outward to form a thermal jet for Exploitation of natural gas hydrate by jet fracture.

[0039] The thermal jet natural gas hydrate extraction device in the present invention combines thermal development and high-pressure jet flow on the coiled pipe 2 capable of continuous rotary drilling in the natural gas hydrate layer, and adopts the form of jet fracture mining for natural gas hydrate, Effectively realize the development of natural gas hydrate in shallow non-diagenetic formations in the ocean.

[0040] By forming a stable rotating thermal jet, the natural gas hydrate can be effectively cracked, the natural gas hydrate contained in the non-diagenetic formation can be cracked and decomposed, and the hot water c...

Embodiment 2

[0043] In this embodiment, the outside of the coiled tubing 2 is provided with a casing 6, and the end of the casing 6 is an open structure. The coiled tubing 2 extends from the end of the casing 6 and enters the natural gas hydrate layer. Out of the coiled tubing 2 outside the casing 6, the jet is sprayed outward to form a rotating thermal jet that can effectively crack the natural gas hydrate.

[0044]After the gas hydrate layer is decomposed by the rotating thermal jet, a fluid mixture composed of hot water, broken formation particles, gas hydrate debris and part of natural gas can be obtained. The annulus gap between the holes is flowed back to the offshore platform for follow-up treatment; while in the original formation, a fractured cavity will be formed, and the three-dimensional space of the cavity is specifically centered on the continuous tube 2, which is horizontally distributed in the natural gas hydration zone. In the material layer, as the coiled tubing 2 continu...

Embodiment 3

[0049] The coiled tubing 2 in this embodiment is provided with a drilling tool 7, and the coiled tubing 2 connected downstream of the drilling tool 7 protrudes from the casing 6, and rotates and directional drills in the natural gas hydrate layer.

[0050] Specifically, the drilling tool 7 divides the coiled tubing 2 into a non-rotating section and a rotating section driven by the drilling tool 7. The rotating section of the coiled tubing 2 protrudes from the casing 6 and is continuously rotated and oriented under the action of the drilling tool 7. drilled into.

[0051] In the initial stage of the production operation, the installation position of the drilling tool 7 should at least ensure that the rotating section is outside the casing 6, and the natural gas hydrate layer downstream of the end of the casing 6 is exploited; in the subsequent production process, the non-rotating section And the drilling tool 7 can gradually protrude from the casing 6 during the running of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com